Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Key Features & Benefits

- Toughened epoxy for primary and secondary aerospace structures

- Specifically designed for efficient AFP processing

- Controlled flow rheology specifically designed to facilitate a wide range of processing for AC, OOA and Press cures

- Processes in OOA without the need for extensive bagging and pre-vacuum procedures - Wet DMA Tg of 315°F (157°C)

- Dry DMA Tg of 428°F (220°C)

- Capable of low laminate void content < 1%

- Product Forms

- Available AFP product forms

- 0.125”+/-0.005” (3.18 mm +/-0.13 mm)

- 0.250” +/-0.005”(6.35 mm +/-0.13 mm)

- Unidirectional (UD) Tape up to 48”(1.2 m) width

- Woven fabric prepreg up to 60” (1.5 m) width

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Applications / Qualifications

- Primary and Secondary Aerospace Structures fabricated with AFP processes

- Wings / Control Surfaces / Airframes

- Turbofan Engine Components

- Nacelles/ Fan Reversers

- Air Ducting

- Fairings

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Fabric Area Weight | 145±5 | gsm | — |

| Prepreg Resin Content | 35±2 | % | — |

| Resin Flow (350°F/177°C, 50psi) | 8-20 | % | — |

Technical Details & Test Data

- Mechanical Properties

AFP Laid-up Panels, Autoclave

HTS45E23/E-752-LT @ 35% RC, 145 gsm FAWProperty Layup Condition Test Method Units Avg. 0° Tensile Strength [0°]8 RTA ASTM D3039 ksi Mpa 325 2243 0° Tensile Modulus [0°]8 RTA ASTM D3039 msi Gpa 19.8 136.6 0° Compressive Strength [0°]8 RTA SRM 1R-94 ksi Mpa 242 1668 0° Compressive Modulus [0°]8 RTA SRM 1R-94 msi Gpa 17.1 117.9 90° Compressive Strength [0°]16 RTA SRM 1R-94 ksi Mpa 49.5 341 90° Compressive Modulus [0°]16 RTA SRM 1R-94 msi Gpa 1.4 10.0 ±45° Inplane Shear Strength*[± [±45°]2s RTA ASTM D3518 ksi Mpa 12.6 87 ±45° Inplane Shear Modulus [±45°]2s RTA ASTM D3518 msi Gpa 0.6 4.3 D3518msiGPa0.64.3Open Hole Tensile Strength ([0°/45/90/-45]s)2 RTA ASTM D5766 ksi Mpa 53.5 369 D3518msiGPa0.64.3Open Hole Tensile Modulus ([0°/45/90/-45]s)2 RTA ASTM D5766 msi Gpa 7.5 51.9

Storage & Handling

- Prepreg Storage Life

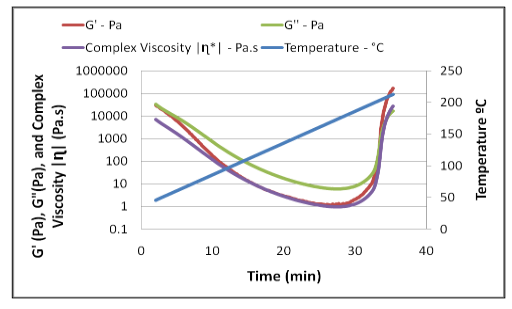

E-752-LT Cure Scan Rheology0.05% Strain, 1Hz 5°C/minWide Process Controlled Flow Window

- Prepreg Storage Life

- Tack Life: Contact Park Engineering

- Out Life: Contact Park Engineering

- Shelf Life: 12 months @ 0°F (-18°C)