Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Key Features & Benefits

- Autoclave, Out-of-Autoclave and Press Cure with low void content

- Service temperatures up to 270°F - Wet

- Controlled resin flow enables robust processing

- Optimized for medium level tack for hand lay-up and automated processes

- Used for both laminate and honeycomb core structures

- Product Forms

- Available on a wide variety of reinforcements, including Fabrics and Unidirectional Tape available up to 60” (1.5m) wide

- Precision slit tape for Automated Fiber Placement (AFP) (0.250”), (0.125”) and other widths upon request

- Compatible with Autoclave, Vacuum Bag/Oven or Press Molding processes

- Data available for wide array of reinforcements including T800 12K UD, IMS65 12K UD, IM7 12K UD, HTS45 12K UD, AS4 3KPW, HTS40 3KPW, T830 6KPW, T830 6K8HS

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Applications / Qualifications

- Primary and Secondary Aircraft Structures

- Control Surfaces

- Wings

- Fairings

- Nacelles / Thrust Reversers

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Fabric Area Weight | 145 | gsm | — |

| Prepreg Resin Content | 35 | % | — |

| Resin Flow (350°F, 100psi, 20 min) | 18 | % | — |

| Volatiles (350°F, 8 min) | max. 0.5 | % | — |

| Gel Time | 600 | Seconds | — |

| Dry Tg / Wet Tg | 209 / 160 | °C | — |

Technical Details & Test Data

- Processing Guidelines

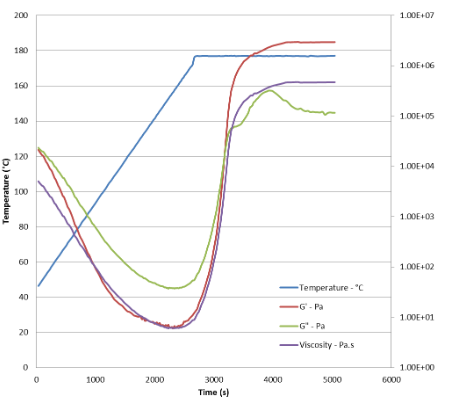

E-752-MTS Resin Rheology Curve

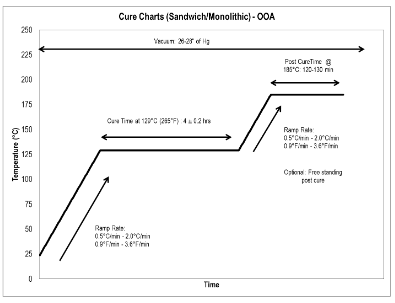

OvenCure Cycle-

Apply 26-28”Hg vacuum - Increase from room temperature to 265 °F (129 °C) at a rate of 0.9-3.6 °F/min (0.5-2.0 °C/min)- Hold cure temperature for 4 hrs +/- 0.2 hrs- Cool down to 150 °F prior to removalOptional Free Standing Post Cure- Increase from 265 °F to 365 °F (129 °C to 185 °C) at a rate of 0.9-3.6 °F/min (0.5-2.0 °C/min)- Hold cure temperature for 120 to 130 minutes- Cool down to 150 °F prior to removal.E-752-MTS Out-of-Autoclave and Autoclave Example Cure Cycles

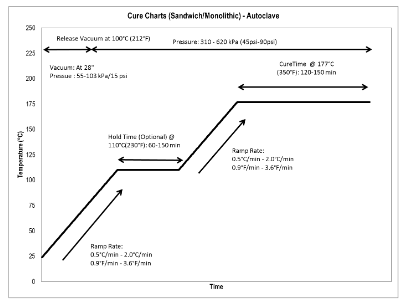

Autoclave Cure Cycle-

Apply 28”Hg vacuum and 15 psi pressure (1 bar)- Increase from room temperature to 230 °F (110 °C) at a rate of 0.9-3.6 °F/min (0.5-2.0 °C/min)- Vent Vacuum when temperature reaches 212 °F (100°C)- Increase pressure from 15 psi to 45 psi (1 bar to 3.1 bar)- Increase from 230 °F to 350 °F (110 °C to 177 °C) at a rate of 0.9-3.6 °F/min (0.5-2.0 °C/min)- Hold cure temperature for 120 to 150 minutes- Cool down to 150 °F and relieve pressure prior to removal

- Mechanical Properties

Property

Lay-up

Condition

HTS45

35%/145gsm UDT

Dry DMA Tg °C

0°

Dry

209

Wet DMA Tg °C

0°

Wet

160

Tension Strength, ksi

0°

RTD

300

-75°F

289

250°F - Dry

300

250°F - Wet

271

90°

RTD

7.8

-75°F

7.8

250°F - Wet

3.7

Tension Modulus, Msi

0°

RTD

18.2

-75°F

17.9

250°F - Dry

18.3

250°F - Wet

18.8

90°

RTD

1.28

-75°F

1.49

250°F - Wet

0.8

Compression Strength, ksi

0°

RTD

242

-75°F

208

250°F - Dry

212

250°F - Wet

156

90°

RTD

42

250°F - Wet

29

Compression Modulus, Msi

0°

RTD

17.7

-75°F

17.6

250°F - Dry

18.2

250°F - Wet

18.0

90°

RTD

1.6

250°F - Wet

1.2

IPS-Str, ksi

[+45°/-45°]2s

RTD

23.8

IPS-Mod, ksi

[+45°/-45°]2s

RTD

0.63

ILSS, ksi

0°

RTD

13.4

G1c, in-psi

0°

RTD

1.3

UNT-Str, ksi

QI Balanced

RTD

114

OHT-Str, ksi

QI Balanced

RTD

54

-75°F

52

UNC-Str, ksi

QI Balanced

RTD

98

250°F - Wet

70

OHC-Str, ksi

QI Balanced

RTD

56

250°F - Wet

39

CAI, ksi (1500 in-lb/in)

QI Balanced

RTD

28