Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Function

Erucamide and oleamide based release aids for polyolefin and TPE (thermoplastic elastomer) processing

Features & Benefits

- Materials Features

- RE- (erucamide) series of slip additive masterbatches for film are

- More cost-effective slip additives compared to low load (5%) alternatives

- Do not contain fillers for enhanced transparency

- Engineered for superb dispersion and slip properties

- RO20 for processing below 220°C

- RE20 for processing above 220°C

- Available from 10-40% loadings

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Uses

These masterbatches are used by injection molders, film processors and compounders to add surface lubrication and mold release properties directly into the resin pellet feed without release sprays or pre-compounded resins. This class of masterbatches can also serve as a process aid. In the case of molybdenum disulfide in nylon, the active ingredient will promote the growth of a fine crystalline structure through nucleation, raising the heat distortion temperature.

- Industry

Film/Sheet Manufacturing, Injection Molding

Properties

- Physical Form

Technical Details & Test Data

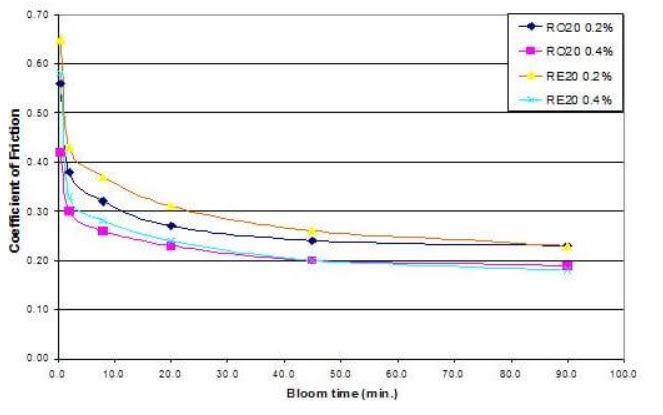

- Slip Bloom Rate RO vs RE in LDPE Film

The high coefficient of friction of LDPE, LLDPE & PP film contributes to adhesion to film or metal surfaces in production. Low erucamide or oleamide levels decrease the film coefficient of friction and reduce or eliminate sticking.

When using these masterbatches, the new coefficient of friction will be a function of both bloom time and letdown.