Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Fibre

- Carbon

- Fibre Type

- TR30s-3K

- Technologies

Features & Benefits

- Materials Features

- Key Features & Benefits

• Cures and is demouldable in 4 minutes at 140°C

• Tg >140°C

• Excellent surface finish

• No thermal cycling of tools required

• Fast Tg development

• Can be preformed

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

- Applications

• Automotive

• Motorsport

• Marine

• Defense- Processing Methods

Pressing

Properties

- Physical Form

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Fabric Weave Style | Twill 2/2 | — | — |

| Fabric Weight | 245 | g/m2 | — |

| Resin Content | 42 | % | — |

| Fibre Volume Fraction | 48 | % | — |

| Thermogravimetry (Dsc) | 140 | °C | — |

| Thermogravimetry (Dma Onset) | 131 | °C | — |

| Thermogravimetry (Dma Peak) | 155 | °C | — |

| Tensile Strength | 840.4 | MPa | ASTM D3039 |

| Tensile Modulus | 63.1 | GPa | ASTM D3039 |

| Interlaminar Shear Strength (Ilss) | 66.9 | MPa | EN ISO 14130 |

| Flexural Strength | 948.2 | MPa | EN ISO 178 |

| Value | Units | Test Method / Conditions | |

| Cure Temperature | 140 | °C | — |

Technical Details & Test Data

- Cure Cyle

Carefully place prepreg preforms in 140°C preheated hot tool. Close tool under 10 bar pressure and

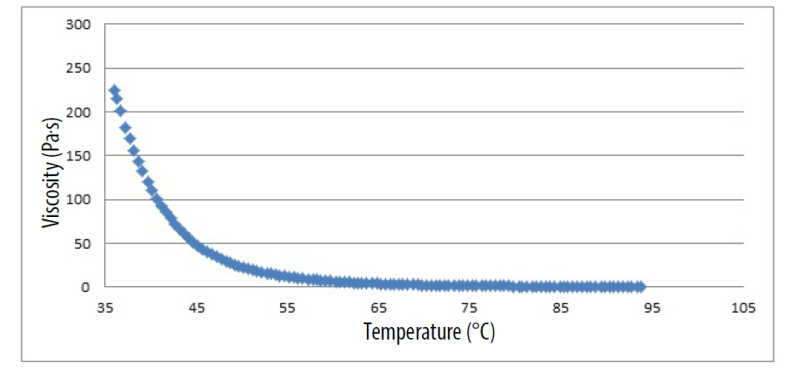

maintain 140°C temperature. Release pressure after 4 minutes and remove cured part.- Viscosity

Storage & Handling

- Storage Conditions

- 6 months at -18°C

- 30 days at 23°C