Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Introduction

There are 2 hardeners varying in reactivity, with pot lives from 20 -30 minutes up to 4 hours. The individual hardeners can be inter-mixed in any ratio, enabling users to optimize the pot life of the system to meet their individual requirements. Cured parts can be worked and demoulded after curing at room temperature. Due to the low vapor pressure of the raw materials, this system can be processed at the elevated temperatures (80 - 100°C) using vacuum processes for example, vacuum assisted RTM. However the maximum temperature will depend on the layer thickness and the geometry of the component part.

Adding an internal parting agent, e.g. zinc stearate, has proven useful for pultrusion processes where profiles with good surface finishes have been produced. Depending on the profile geometry, mold temperatures in the range of 180 - 230°C are possible, thus permitting higher drawing speeds.

It is not expected that there should be compatibility problems with fully cured, dry UP gelcoats or various paint systems (e.g. PUR-based), etc. However, comprehensive tests should be carried out first to confirm this.

The resin and hardeners in this system contain neither solvents nor fillers. Careful selection of raw materials has ensured this system is low in odor and has good physiological properties, minimizing skin irritation and allergy problems. However, the appropriate safety advice regarding contact with, and processing of, epoxy resin system should be followed.- Main Features

Operational Temperature

• -60°C + 50 - 60°C without postcure

• -60°C + 80°C after postcure

Processing

• Between 10°C and 50°C

• Pot life from ca. 45 minutes to ca. 4 hours at 25°C

Processing methods

• Injection molding (RTM)

• Vacuum Infusion

• Pultrusion

Other features

• Good physiological properties

• Very good mechanical properties

• Very low viscosity

• Excellent initial cure at room temperature

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Applications

• Boats and Shipbuilding

• Wind Energy Turbine Blades

• Sports Equipment- Processing Methods

• Injection molding (RTM)

• Vacuum Infusion

• Pultrusion

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density (25°C) | 1.13-1.17 | g/cm3 | — |

| Epoxide Equivalent | 166-185 | — | — |

| Epoxide value | 0.54-0.60 | — | — |

| Viscosity (25°C) | 700-1000 | mPa s | — |

| Color | max. 3 | Gardner | — |

Technical Details & Test Data

- Product Specification

Hardeners RS-MH134 RS-MH137 Density at 25°C (g/cm3) 0.94-1.00 0.94-0.98 Viscosity at 25°c (mPa s) 10-50 10-50 Amine value (mgKOH/g) 550-700 400-500 Color / Gardner max. 4* max. 4* Does not apply to standard hardeners which are colored blue.

- Processing Data Resin

Resin Hardeners RS-M135 RS-MH134 RS-MH137 Average Epoxide Value 0.56 - - Amine Equivalent - 52 52 Processing Temperature

10° - 15°C Mixed viscosity at 25°C

See diagram Setting Temperature

Initial cure at room temperature (20 - 25°

Heat Treatment At temperatures between 40 - 150°C

The optimum processing temperature is between 20°C and 25°C. Higher processing temperatures will reduce the mixed viscosity and shorten the pot life, a rise of 10°C will halve the pot life. Further, water contained in fillers for example, or very high relative humidity will accelerate the reaction of the resin-hardener mixture. However, there is no significant effect to the strength of the cured product as a result of different temperatures and relative humidity levels during processing.

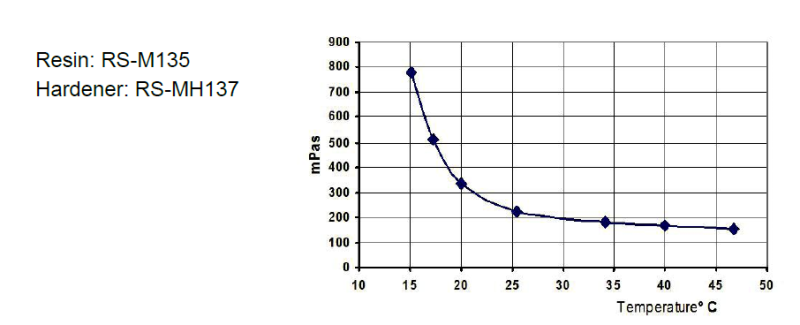

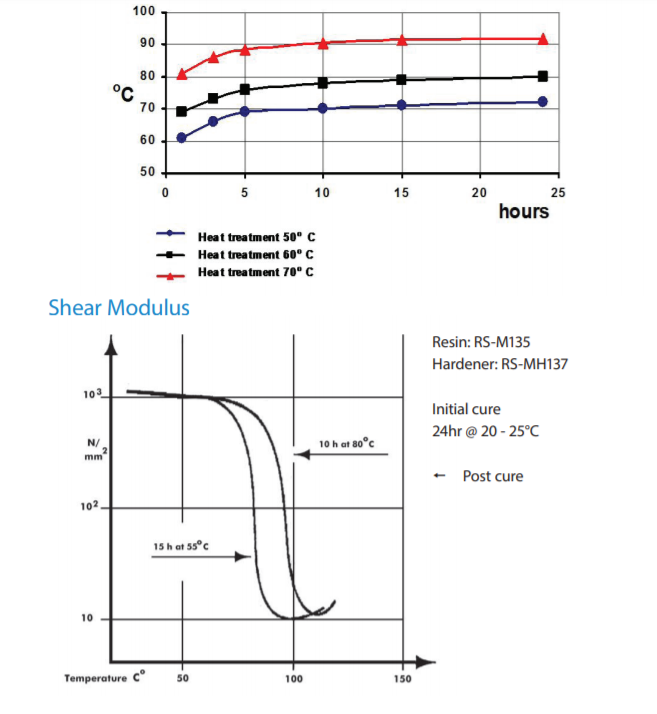

The mixed viscosity is very low, which is especially advantageous for injection and pultrusion methods. By heating the resin mass, the viscosity can be reduced further to approximately 150 mPa s at 46°C (see diagram), enabling complicated molded parts with long flow paths to be easily injected. The temperature rise with hardener RS-MH137 remains very low up to a mold temperature of approximately 30°C, so that even parts with thicker layers can be produced at elevated temperatures.

- Mixing Ratios

RS-M135 : RS-MH134 ~ RS-MH137

Parts by Weight 100 : 30 (+/-1) Parts by Volume 100: 35 (+/-1) The specified mixing ratios must be observed; varying the quantity of hardener will adversely affect the properties of the matrix. The resin and hardener must be mixed thoroughly until they are homogeneously mixed, paying special attention to the walls and the bottom of the mixing container. Do not mix large quantities, especially if highly reactive systems are being used. Heat dissipation from mixing containers is poor, causing the resin-hardener mixture to warm up quickly as a result of the exothermic reaction of the two materials. Temperatures >200°C can be generated causing smoke-intensive burning of the resin-hardener mixture. To avoid this, mix small quantities in large, shallow containers.

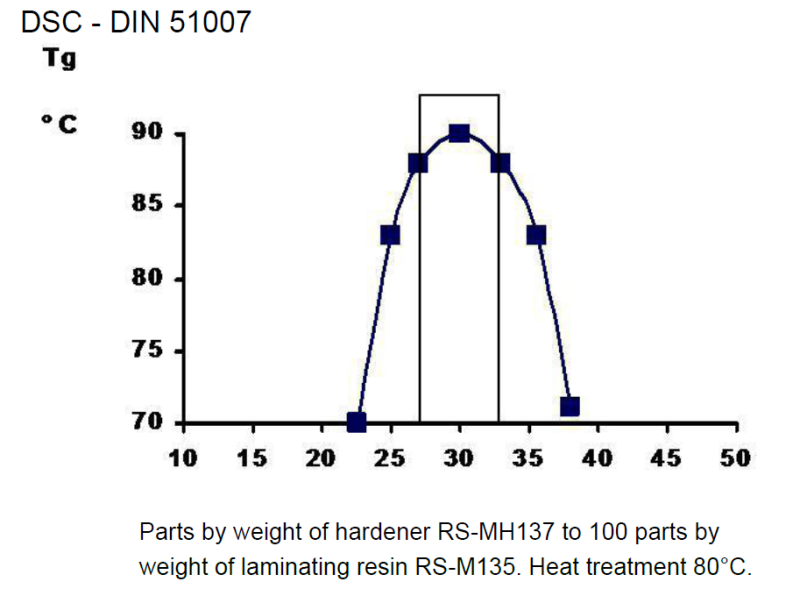

Mixed Ratios <-> Glass Transition Temperature

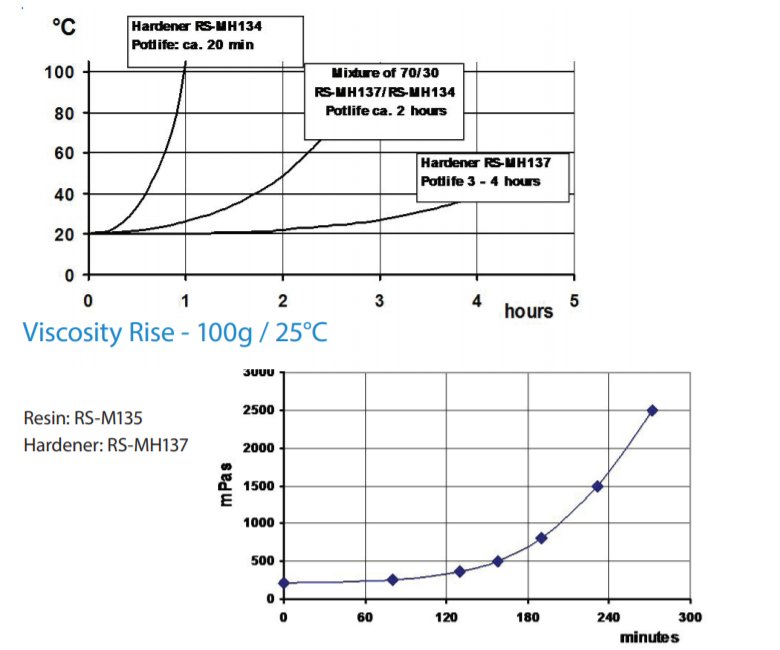

Processing Time (Pot Life) 100g / 25°C

Resin RS-M135 Hardener RS-MH134 RS-MH137 ca. 20 - 30 min 3 - 4 hrs The individual hardeners can be inter-mixed in any ratio, enabling users to optimize the pot life of the system to meet their individual requirements.

For example:

70% RS-MH137 / 30% RS-MH134 will provide a pot life of ca. 2 hours, as shown below.

- Resin Matrix Properties

Glass Transition Temperature (Tg)

Resin RS-M135 / Hardener RS-MH137

- Cured - Un-reinforced Matrix Properties

CURING : 24h @ 23°C + 15h @ 60°C

RS - M135 & RS-MH134 / RS-MH137

Density g/cm3 1.18 - 1.20 Flexural strength N/mm2 110 - 140 Tensile strength N/mm2 70-80 Impact Strength Nmm/mm2 40-50 Elongation % 5-6.5 Compression strength N/mm2 120-140 Modulus of elasticity kN/mm2 3.3-3.5 Water absorption 24 hours / 23°C % 0.10-0.20 Water absorption 7 days / 23°C % 0.20-0.50 Shore Hardness D 80-85 Fatigue under reverse bending stresses acc. DLR Brunswick 10%

min. 1 x 106 Fatigue under reverse bending stresses acc. DLR Brunswick 90%

min. 2 x 106 Representative data in accordance with WL 5.3203 parts 1 & 2 of the German Aviation Materials Manual, part II

RS-- Composite Properties Cured - Fibre Reinforced Properties

CURING: 24h @ 25°C + 15h @ 60°C

Vf 43% RS - M135 & RS-MH134 / RS-MH137

Flexural strength N/mm2 GFC 510 - 560 Flexural strength N/mm2 CFC 720-770 Flexural strength N/mm2 AFC 350-80 Tensile strength N/mm2 GFC 460-500 Tensile strength N/mm2 CFC 510-550 Tensile strength N/mm2 AFC 400-480 Compressive strength N/mm2 GFC 410-440 Compressive strength N/mm2 CFC 460-510 Compressive strength N/mm2 AFC 140-160 Interlaminar shear strength N/mm2 GFC 42-46 Interlaminar shear strength N/mm2 CFC 47-55 Interlaminar shear strength N/mm2 AFC 29-34 Flexural modulus kN/mm2 GFC 20-24 Flexural modulus kN/mm2 CFC 40-45 Flexural modulus kN/mm2 AFC 16-19 GFC - samples: 16 layers, glass fabric, 296g/m2 8H Satin, 4mm thick.

CFC - samples: 8 layers, SM, 3K carbon fabric, 200g/m2 plain weave, 2mm thick.

AFC - samples: 15 layers, Kevlar® aramid fabric, 170g/m2 4H Satin, 4mm thick.

Fiber volume fraction of samples 40%-45%. Data calculated to fiber volume 43%.

Safety & Health

- Caution

• Do not heat over a naked flame;

• Before warming, open containers to equalize pressure;

• Use safety equipment (gloves, safety glasses, respirator);

• Work in a well ventilated area.

Storage & Handling

- Storage

The hardeners can be stored for a minimum of 12 month in original, sealed containers at 15 - 25°C. Crystallization of these materials may occur at temperatures below 15°C and is visible as a clouding or solidification of the liquid within the container. Before processing, the crystallization must be removed. This can be done, without any degradation to the product, by slowly warming the material to approximately 50 - 60°C in a water bath or oven and stirring or mixing until the liquid becomes clear.