Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Applications

- Carrier Resin - PE

- Additive Type - Inorganic Infra-Red Absorber

Properties

- Physical Form

Technical Details & Test Data

- Film Recipe

FILM RECIPE Film

thickness

(mic)Infra-Red

transmittance

(%)Clarity

(%)Trans mittance

(%)Haze

(%)100% metallocene polyethylene resin (reference) 150 68,2 97.6 92.8 13.9 95% metallocene polyethylene resin + 5% IR550 150 79,8 79.8 91 32.4 92% metallocene polyethylene resin + 8% IR550 150 68.5 68.5 90.2 44.5 90% metallocene polyethylene resin + 10% IR550 150 62.9 62.9 89.3 51.1 - Film Recipe (Graphs)

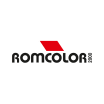

Graph 1 - Infra-Red effect in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

Graph 1 - Infra-Red effect in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

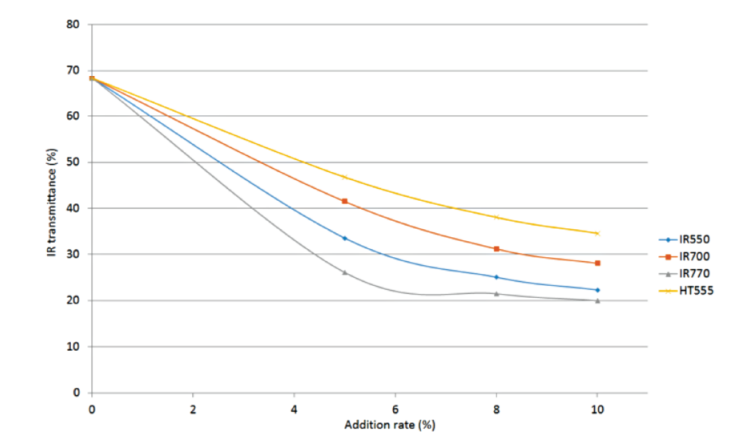

Graph 2 - Film clarity in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

Graph 2 - Film clarity in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

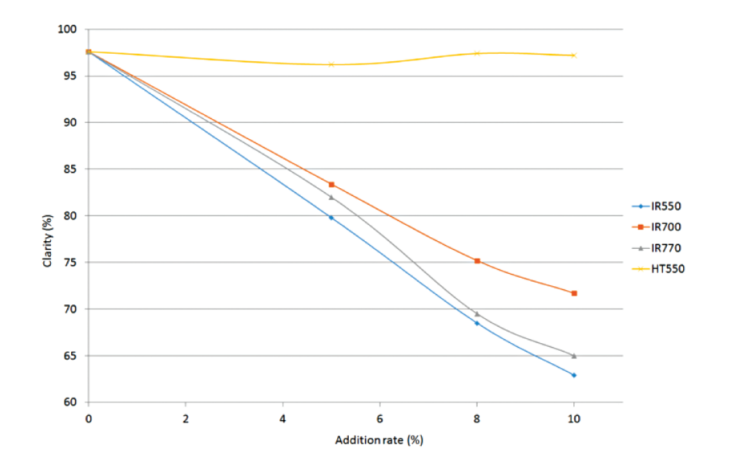

Graph 3 - Transmittance in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

Graph 3 - Transmittance in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

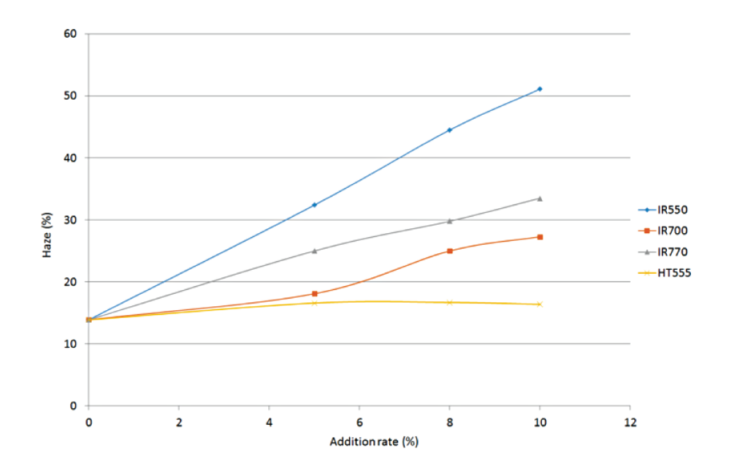

Graph 4 - Haze in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

Graph 4 - Haze in relationship to the masterbatch addition rates in a 150mic film made of metallocene polyethylene resin.

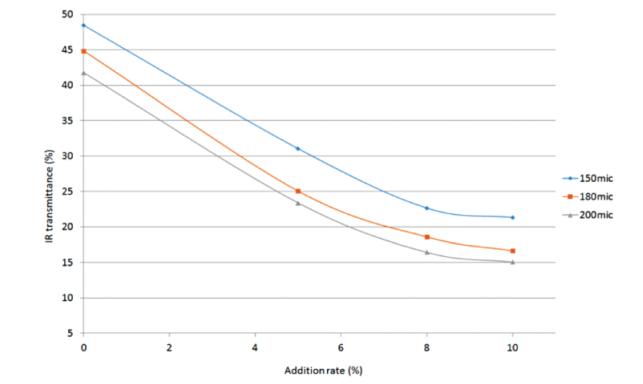

Graph 5 - IR effect in relationship to the KRITILEN® IR550 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

Graph 5 - IR effect in relationship to the KRITILEN® IR550 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

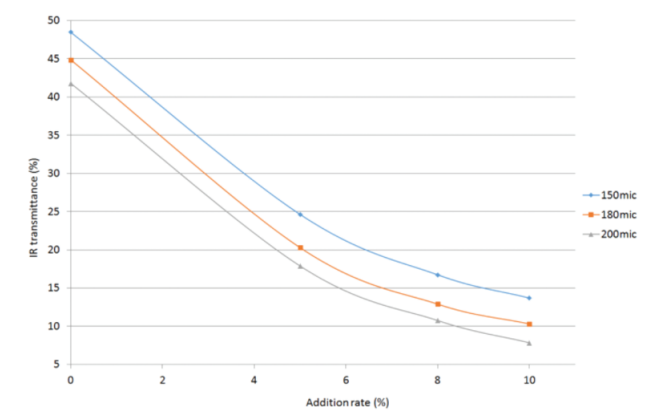

Graph 6 - IR effect in relationship to the KRITILEN® IR700 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

Graph 6 - IR effect in relationship to the KRITILEN® IR700 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

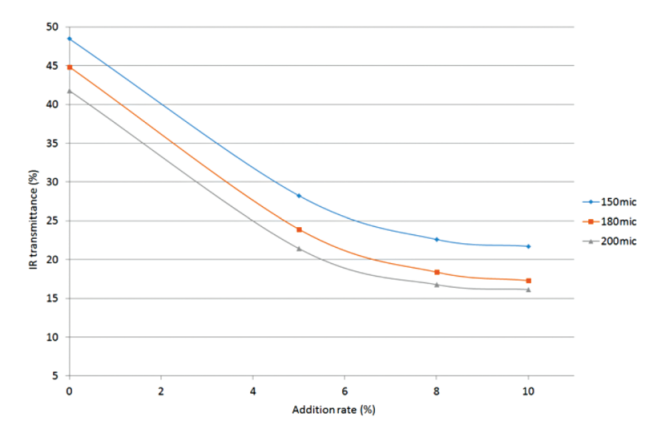

Graph 7 - IR effect in relationship to the KRITILEN® IR770 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

Graph 7 - IR effect in relationship to the KRITILEN® IR770 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

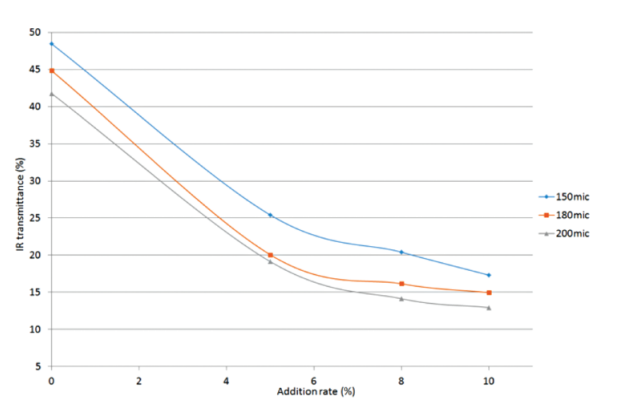

Graph 8 - IR effect in relationship to the KRITILEN® HT555 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

Graph 8 - IR effect in relationship to the KRITILEN® HT555 addition rates in different film thicknesses (in a film made of metallocene polyethylene resin and 25% EVA - 14% VA content).

Packaging & Availability

- Packaging Type