Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Foam Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Characteristics

- Breathable

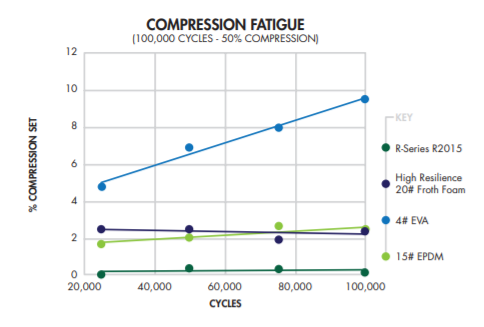

- Superb Compression Fatigue Properties

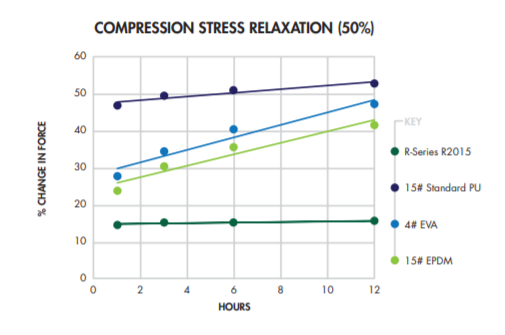

- Excellent Stress Relaxation Resistance

- Low Compression Set

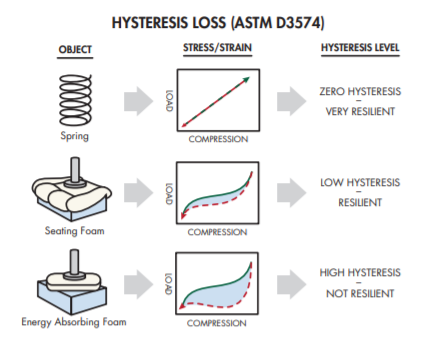

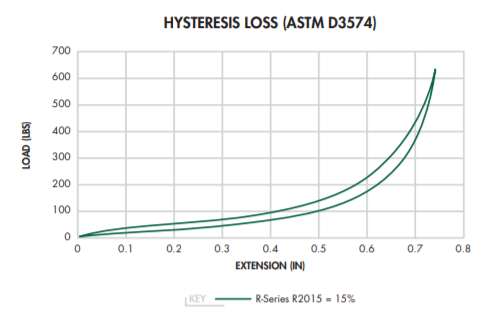

- Low Hysteresis Loss

- Dimensionally Stable

Applications & Uses

- Markets

Properties

- Color

- Physical Form

- Physical Properties

| Value | Units | Test Method / Conditions | |

| CFD (25%) | 4.0 | psi | ASTM D3574 |

| CFD (25%) | 15.0 | psi | ASTM D3574 |

| Compression Deflection (25%) | 15.0 | psi | ASTM D1056 |

| Compression Deflection (25%) | 2022-03-07 | psi | ASTM D1056 |

| Compression Set (50%, 70°C) | 2.5 | % | ASTM D3574 |

| Compression Set (50%) | 0.5 | % | ASTM D1056 |

| Compression Set (50%) | max. 3 | % | ASTM D1056 |

| Compression Set (50%) | max. 10 | % | ASTM D3S74 |

| Density | 20.0 | pcf | ASTM D3574 |

| Density | 2022-10-14 | pcf | ASTM D3574 |

| Elongation | 130.0 | % | ASTM D3574 |

| Elongation | 160.0 | % | ASTM D3574 |

| Flammability (minimum thickness TBD) | Pass | — | FMVSS-302 |

| Hysterisis Loss | 15.0 | % | ASTM D3574 |

| Resilience | 55.0 | % | ASTM D2632 |

| Resilience | 42.0 | % | ASTM D2632 |

| Service Temperature | 40 - 250 | °F | — |

| Tear Strength | 14.0 | lb/in | ASTM D624 |

| Tear Strength | 8.0 | lb/in | ASTM D624 |

| Tensile Strength | 70.0 | psi | ASTM D3574 |

| Tensile Strength | 42.0 | psi | ASTM D3574 |

Technical Details & Test Data

- Compression Fatigue

The most visible signature of fatigue is compaction – the material fails to recover to its original thickness after repetitive or long term compression. Compaction is quantified as “compression set”, a relationship between the original thickness (T) and the compacted thickness (t), expressed as % loss. Compression set is the result of plastic deformation of cell walls and the reduced resilience of damaged cells. R-Series performance is exceptional with virtually zero compression set or degradation of cellular structure providing a superior alternative for many demanding applications.

- Stress Relaxation

Defined as a gradual decrease in stress with time under a constant deformation or strain. This polymer behavior is studied by applying a constant deformation to the specimen and measuring the stress required to maintain that strain as a function of time. Basically, it quantifies the stress lost by the material over time while maintaining a constant strain. R-Series maintains this stress much longer than standard foams, making it an ideal performance material for demanding gasket and die ejection applications.

- Hysteresis Loss

The measure of the energy lost or absorbed by a foam when deflected by a specified strain and immediately recovered at the same strain rate to its original thickness, it is the area between the loading and unloading curves on a hysteresis loop. R-Series, with a resilience of 50% extraordinary compression resistance properties, exhibits very low hysteresis loss of just 15% making it an advantaged material for high energy return applications.

Packaging & Availability

- Packaging Type

- Availability

- 60” wide rolls in 50’ and 100’ lengths, skived to custom thicknesses.

- Available with PSA or laminated fabrics.

- Colors and additives, such as anti-microbial, are available depending on volume.

- Standard 60 inch (1.52 meter) wide rolls with capabilities to produce in various widths.

- Available in 50 feet (15.24 meters)’ and 100 feet (30.48 meters) lengths, skived to custom thicknesses.

- Available with adhesives, laminated fabrics , films, custom coatings or composites.

- Various color options available with the ability to custom color match using our fully reacted colorants.

- Other additives, such as anti-microbial and flame retardants, are available depending on sales opportunities and volume.