Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Achieving a unique balance of properties in a model cast polyurethane formulation with SABIC’s specialty additive offers:

- Improved toughness and increased hardness

- Increased tensile strength and elongation

- Improved modulus

- Higher temperature resistance

- Improved resistance to solvent, water and alkaline or acidic water

Applications & Uses

- Markets

- Applications

- Applications

- Coated Pipes

- Tires and Wheels

- Rollers

- Gaskets / O- Rings

Potential applications

Hot cast elastomer solutions may benefit applications that require more durability and better performance at high temperatures and under hydrolytic conditions. Potential applications include print rollers, protective coatings on pipes for slurry pumping applications, PU wheels,seals and gaskets, tires and mining screens.

Properties

- Physical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Hydroxy Equivalent Weight | 880 | g/eq | SABIC method |

| Moisture Content | max. 0.5 | % | SABIC method |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature (Half-width) | 140 | °C | SABIC method |

Technical Details & Test Data

- Improving Performance in Cast Polyurethane Systems in Mdi-fbdo Formulations

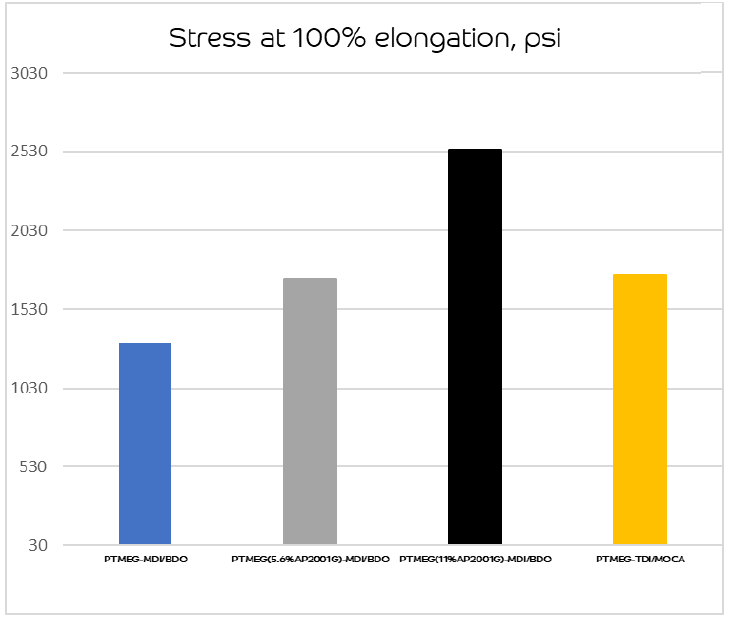

SABIC’s NORYL™ AP2001G polyol in MDI-BDO formulations can provide enhancements in stiffness, toughness and hardness. Additional benefits to these formulations include an increase in cohesive strength and demonstrated retention of physical properties at elevated temperatures. These benefits were observed when compared to standard MDI-BDO and TDI-MOCA formulations. Improvements in chemical and environmental resistance can also be achieved with the inclusion of NORYL AP2001G polyol.

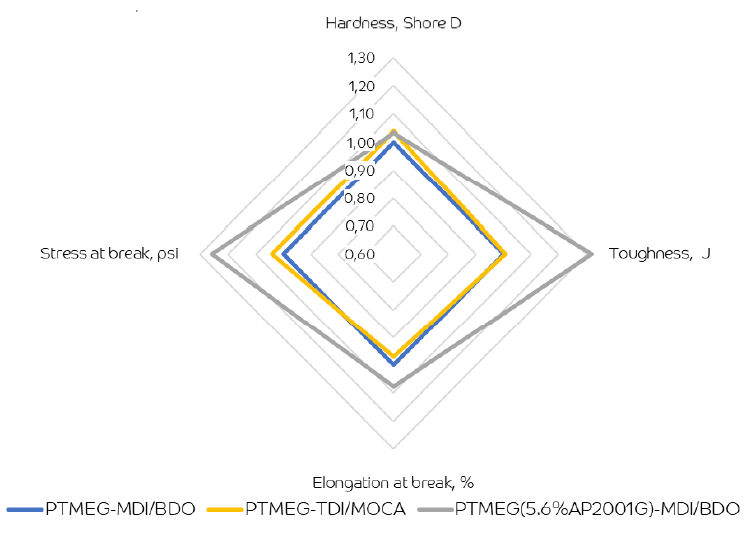

Relative Performance of Ptmeg-based Cast PU Formulations

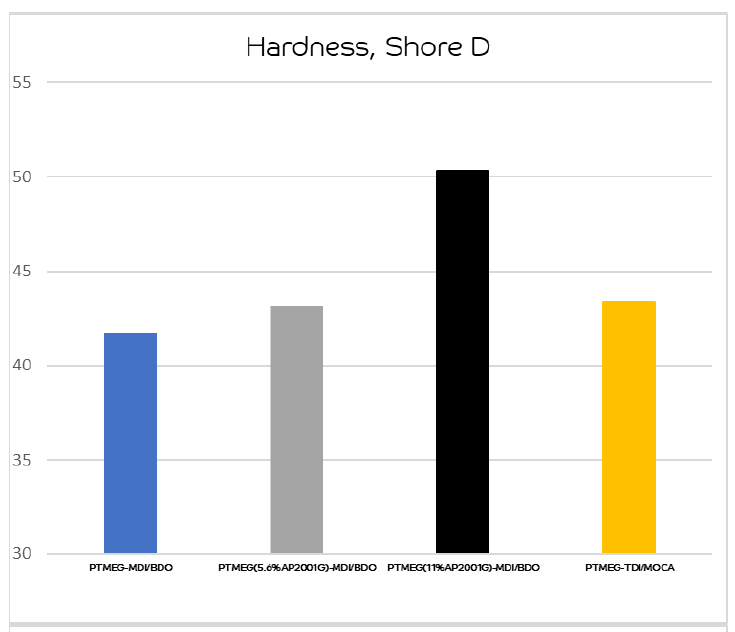

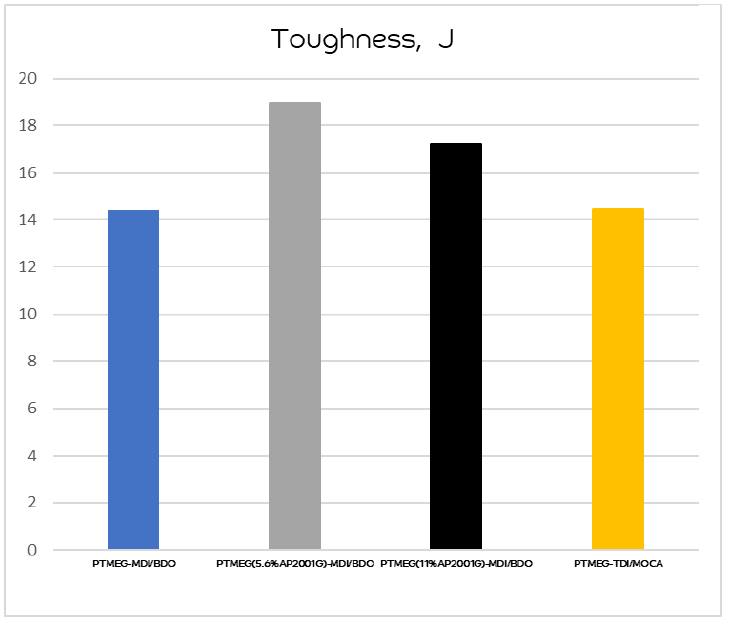

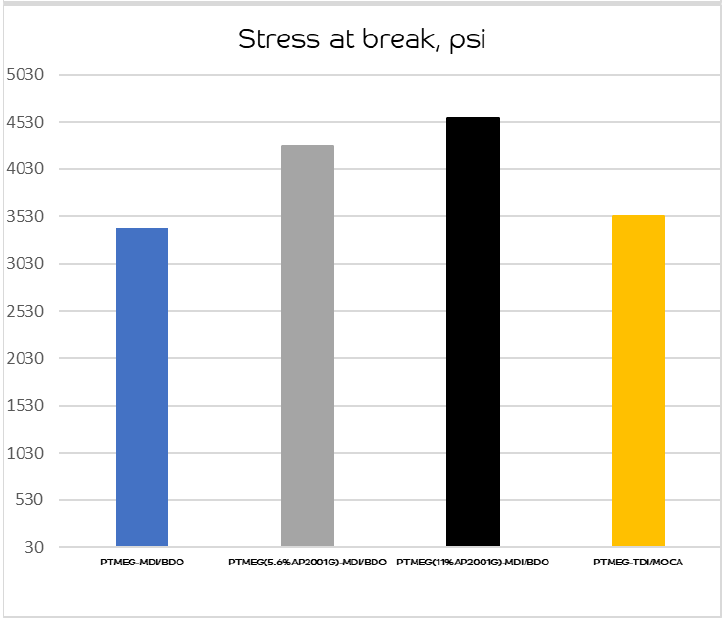

Adding 5.6% of NORYL AP2001G polyol to a standard MDI-BDO Cast PU formulation yielded significantly improved mechanical properties (+8% elongation; +26% tensile strength; +30% toughness and +1.4 shore D points of hardness) at room temperature (20° C).

- NORYL™ AP2001G Polyol Solution Performance Data

The potential benefits of the formulation containing NORYL AP2001G polyol versus standard MDI-BDO include:

- Increased hardness

- Higher modulus and tensile strength

- Improved elongation and toughness at room temperature

Packaging & Availability

- Country Availability

- Regional Availability