Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

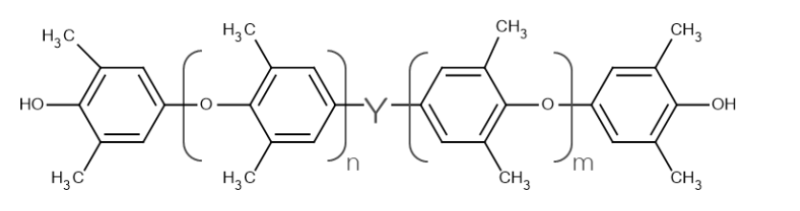

- Chemical Structure

NORYL SA90 RESIN

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Compatible Polymers & Resins

Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Solubility of NORYL™ SA90 Resin in Common Solvents

Solubility was determined by dissolving 30 wt.% NORYL SA9000 resin in the listed solvent at ambient temperature and with agitation for 1 hour.

Solvents Solubility of NORYL™ SA90 Resin Solution stability after 7 days Aromatic Toluene Y Clear Anisole Y Clear Xylene Y Cloudy Alcohols Methanol N Ethanol (denatured) N Butanol N Isopropyl Alcohol N Ethylene Glycol N Ketones Acetone N Methyl ethyl ketone (MEK) Y Cloudy Cyclohexanone Y Clear Methyl isobutyl ketone (MIBK) Y Cloudy Esters Methyl acetate Y Cloudy Ethyl acetate Y Cloudy Butyl acetate Y Cloudy Isopropyl acetate Y Cloudy Amyl acetate Y Cloudy Polar aprotic solvents N,N-dimethyl formamide (DMF) Y @ 75

°CSettled N,N-dimethyl acetamide (DMAc) Y Cloudy N-methyl pyrrolidone (NMP) Y @ 60

°CSettled Acids Acetic acid N Ethers Dioxane Y Cloudy 2-methoxyethanol N Tetrahydrofuran Y Cloudy Ethylene glycol monobuty! ether Y @ 120

°CSettled 2-ethoxyethyl acetate Y Cloudy

| Value | Units | Test Method / Conditions | |

| Hydroxy Equivalent Weight | 840 | g/eq | SABIC method |

| Intrinsic Viscosity | 0.09 | dl/g | SABIC method |

| Phenolic End Group Content | 21500 | ppm | SABIC method |

| Mn | 1600 | — | SABIC method |

| Solubility (In Toluene, at 21°C) | 50 | Wt. % | SABIC method |

| Solubility (In Methyl Ethyl Ketone, at 21°C) | 50 | Wt. % | SABIC method |

| Specific Gravity | 1.02 | — | ASTM D792 |

| Viscosity (at 50 wt% in toluene, 25°C) | 298 | cP | SABIC method |

| Viscosity (at 50 wt% in methyl ethyl ketone, 25°C) | 160 | cP | SABIC method |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature (Half-width) | 140 | °C | SABIC method |

| Value | Units | Test Method / Conditions | |

| Dielectric Constant (at 1 MHz) | 2.54 | — | ASTM D150 |

| Dissipation Factor (at at 1 MHz) | 0.0007 | — | ASTM D150 |

Technical Details & Test Data

- Procedure for Dissolving NORYL™ SA90 Resin into Epoxy Resins

STEPS:

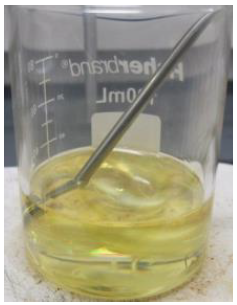

1. Charge vessel (beaker) with epoxy resin and place on magnetic hot plate with a stirrer.

2. Heat epoxy resin up to the temperature provided in the tables on subsequent pages.

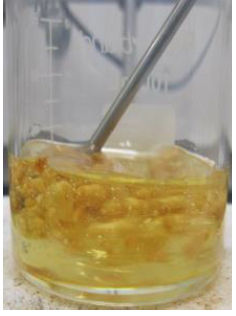

3. Once the desired temperature is reached, add 25% of the total NORYL SA90 resin to

avoid agglomeration. Maintain stirring until NORYL SA90 resin is completely dissolved.

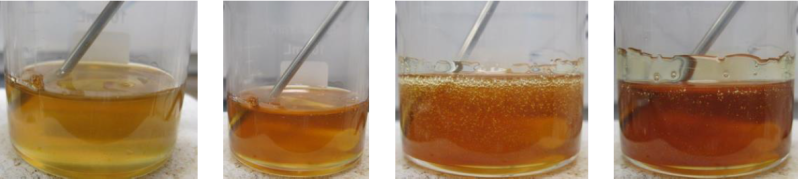

4 - 6. Repeat step 3, adding 25% at a time, until 100% of the NORYL SA90 resin is dissolved.

Step 1

Step 2

Step 3 Step 4 Step 5 Step 6

Photos:

Dissolution of 10% NORYL SA90 resin in EPON® resin 164 shown above.

The dissolution time for each addition is approximately 20 minutes.OTHER CONSIDERATIONS:

- Using resin kettles and/or round bottom flasks may potentially reduce the dissolution time.

- The starting temperature and dissolution time will be dependent on the type of the epoxy resin and the amount of NORYL SA90 resin. Please refer to the subsequent tables dissolution time and temperature.

- Minimum dissolution temperature should be above the Tg of NORYL SA90 resin (135- 145°C)

- There may be a reaction between NORYL SA90 resin and epoxy resin during dissolution. The degree of reaction may be dependent on the amount of NORYL SA90 resin, the type of the epoxy resin, the dissolution time and temperature.

- These studies were completed at lab scale. Please consider reaction rates and temperatures when processing at larger scale.

Packaging & Availability

- Country Availability

- Regional Availability