Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Potential Benefits of LEXAN EXL Resin

- Impact: Best-in-class ductility to -60 ºC with an outstanding balance of ductility and viscosity.

- Weatherability: Excellent retention of mechanical properties upon outdoor exposure.

- Aging: Better retention of properties vs. other polycarbonate resins.

- Flame retardance: FR grades can be used in many ECO-compliant applications.

- Knitline strength: A significant improvement over PC/ABS material

- Chemical resistance: Improved chemical resistance to some chemicals compared to standard polycarbonate

- Mechanical Recycling

Process

Debris are washed, melted & transformed into raw material for a new process. Focus on responsible sourcing of high-quality waste streams

Certification

Third-party certification of PCR content conducted by SCS Global Services

Value Proposition

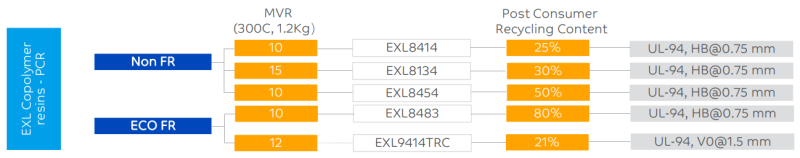

- 21-80% post-consumer recycled content

- Meeting RoHS1 guidelines

- Provides CO2

- reduction & waste depletion options

- Non-brominated & non-chlorinated flame retardant systems

- Up to 2 extra EPEAT points can be achieved

- Broad color space, enhanced performance via

- blending with copolymers

- Drop in solution to existing tools

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color

- Flame Rating

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

- Impact Properties

- Injection Molding

- Flame Characteristics

- Note

- ʰ Measurements made from laboratory test coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Yield, Type I, 50 mm/min) ¹¹ | 57 | MPa | ASTM D638 |

| Tensile Stress (Break, Type I, 50 mm/min) ¹¹ | 55 | MPa | ASTM D638 |

| Tensile Strain (Yield, Type I, 50 mm/min) ¹¹ | 6 | % | ASTM D638 |

| Tensile Strain (Break, Type I, 50 mm/min) ¹¹ | 100 | % | ASTM D638 |

| Tensile Modulus (at 5 mm/min) ¹¹ | 2200 | MPa | ASTM D638 |

| Flexural Stress (Yield, 1.3 mm/min, 50 mm span) ¹¹ | 90 | MPa | ASTM D790 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ | 2100 | MPa | ASTM D790 |

| Value | Units | Test Method / Conditions | |

| Specific Gravity ¹¹ | 1.2 | — | ASTM D792 |

| Mold Shrinkage (flow, 3.2 mm) ʰ ¹¹ | 0.4 - 0.8 | % | SABIC method |

| Melt Flow Rate (at 300°C, 1.2 kgf) ¹¹ | 10 | g/10 min | ASTM D1238 |

| Water Absorption (at 23°C, 24hrs) ¹¹ | 0.15 | % | SABIC method |

| Value | Units | Test Method / Conditions | |

| Vicat Softening Temperature (Rate B/50) ¹¹ | 145 | °C | ASTM D1525 |

| Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ | 123 | °C | ASTM D648 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ | 0.00006 | 1/°C | ASTM E831 |

| Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ | 0.00006 | 1/°C | ASTM E831 |

| Relative Temperature Index (Electrical) ᵖ ¹¹ | 80 | °C | UL 746B |

| Relative Temperature Index (Mechanical with impact) ᵖ ¹¹ | 80 | °C | UL 746B |

| Relative Temperature Index (Mechanical without impact) ᵖ ¹¹ | 80 | °C | UL 746B |

| Value | Units | Test Method / Conditions | |

| Volume Resistivity ¹¹ | min. 1.E+15 | Ω.cm | ASTM D257 |

| Surface Resistivity ¹¹ | min. 1.E+15 | Ω | ASTM D257 |

| Dielectric Strength (in oil, at 0.8mm) ¹¹ | 15 | kV/mm | ASTM D149 |

| Relative Permittivity (1 MHz) ¹¹ | 3 | — | ASTM D150 |

| Dissipation Factor (at at 1 MHz) ¹¹ | 0.0093 | — | ASTM D150 |

| Hot Wire Ignition (PLC 3) ¹¹ | min. 3 | mm | UL 746A |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Notched, at 23°C) ¹¹ | 800 | J/m | ASTM D256 |

| Izod Impact (Notched, at -30°C) ¹¹ | 700 | J/m | ASTM D256 |

| Izod Impact (Notched, at -40°C) ¹¹ | 650 | J/m | ASTM D256 |

| Instrumented Dart Impact Total Energy (at 23°C) ¹¹ | 70 | J | ASTM D3763 |

| Charpy Impact (at 23°C, V-notch Edgew 80*10*3 sp=62mm) ¹¹ | 67 | kJ/m² | ISO 179/1eA |

| Charpy Impact (at -30°C, V-notch Edgew 80*10*3 sp=62mm) ¹¹ | 58 | kJ/m² | ISO 179/1eA |

| Charpy Impact (at -40°C, V-notch Edgew 80*10*3 sp=62mm) ¹¹ | 54 | kJ/m² | ISO 179/1eA |

| Charpy Impact (at 23°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ | 65 | kJ/m² | ISO 179/1eA |

| Charpy Impact (at -30°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ | 27 | kJ/m² | ISO 179/1eA |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 120 | °C | — |

| Drying Time ⁷ | 3 - 4 | Hrs | — |

| Drying Time (Cumulative) ⁷ | 48 | Hrs | — |

| Maximum Moisture Content ⁷ | 0.02 | % | — |

| Melt Temperature ⁷ | 295 - 315 | °C | — |

| Nozzle Temperature ⁷ | 290 - 310 | °C | — |

| Front - Zone 3 Temperature ⁷ | 295 - 315 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 280 - 305 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 270 - 295 | °C | — |

| Mold Temperature ⁷ | 70 - 95 | °C | — |

| Back Pressure ⁷ | 0.3 - 0.7 | MPa | — |

| Screw Speed ⁷ | 40 - 70 | rpm | — |

| Shot to Cylinder Size ⁷ | 40 - 60 | % | — |

| Vent Depth ⁷ | 0.025 - 0.076 | mm | — |

| Value | Units | Test Method / Conditions | |

| UL Recognized (94HB Flame Class Rating) ᵖ | min. 0.75 | mm | UL 94 |

| UL Recognized (94HB Flame Class Rating) ᵖ | min. 0.4 | mm | UL 94 |

| Glow Wire Ignitability Temperature (at 3.0 mm) ᵖ | 875 | °C | IEC 60695-2-13 |

| Glow Wire Ignitability Temperature (at 1.5 mm) ᵖ | 875 | °C | IEC 60695-2-13 |

| Glow Wire Ignitability Temperature (at 1.0 mm) ᵖ | 875 | °C | IEC 60695-2-13 |

| Glow Wire Ignitability Temperature (at 0.75 mm) ᵖ | 850 | °C | IEC 60695-2-13 |

| Glow Wire Flammability Index (at 3 mm) ᵖ | 960 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at 1.5 mm) ᵖ | 850 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at 1 mm) ᵖ | 850 | °C | IEC 60695-2-12 |

| Glow Wire Flammability Index (at 0.75 mm) ᵖ | 825 | °C | IEC 60695-2-12 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- EXL Copolymer Resins: Low Temperature, High Impact Resistance with Post Consumer Recycling Material Solutions

Packaging & Availability

- Regional Availability