Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Characteristics

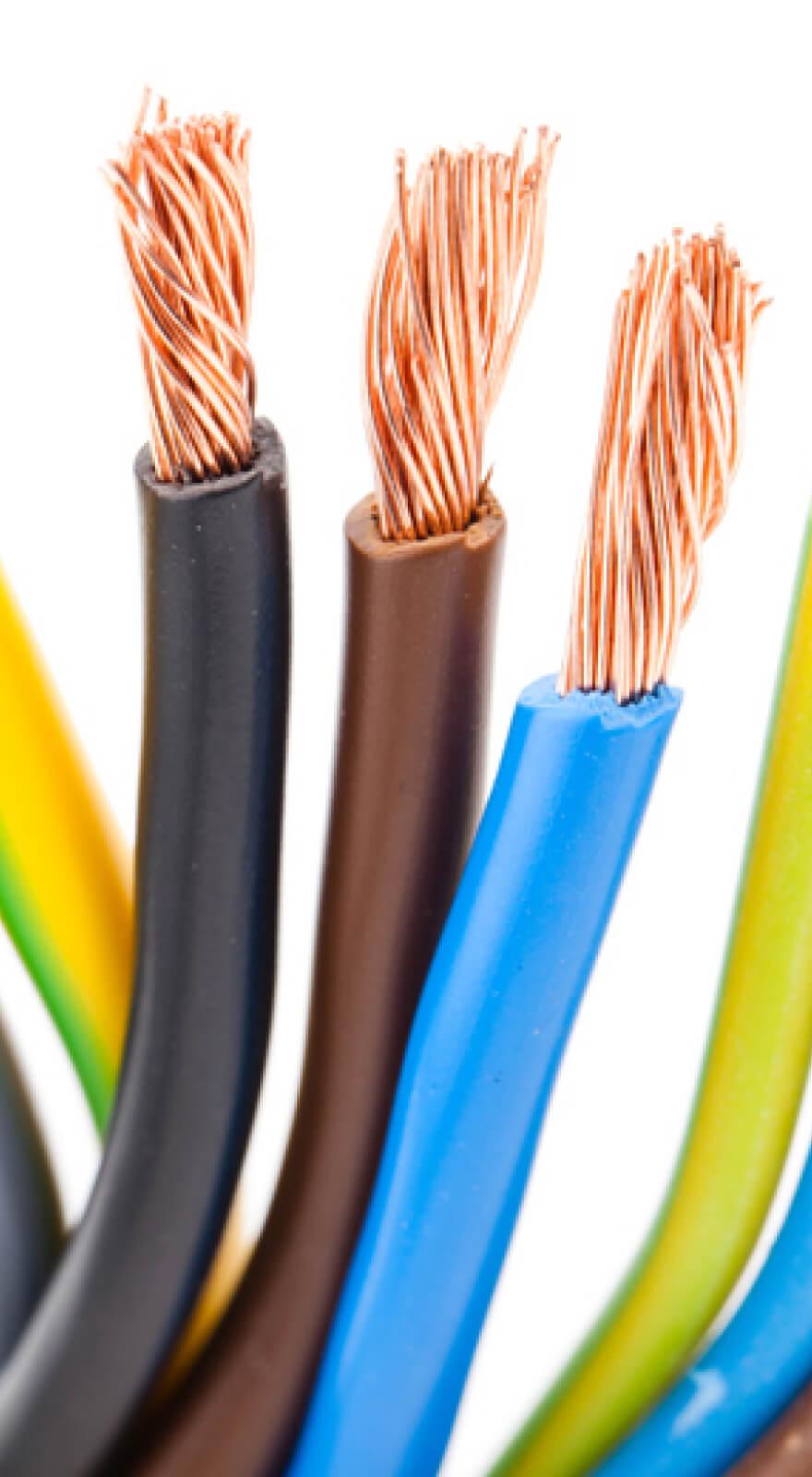

Silane crosslinkable EPR compound for low and medium voltage power cable insulation

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Appearance

- Pellets

- Mechanical Properties

- Physical Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Elongation at Break | 420 | % | IEC 60811-501 |

| Elongation at Break (After Thermal Aging: 7 Days at 135°C) | 8 | % Variation | IEC 60811-401 UL 1581 & UL 2556 |

| Elongation Under Load (20 N/cm² load at 250°C) (Cure Assessment by Hot Set Test: Force cured at 80°C in water.) | 100 | % | IEC 60811-507 |

| Ozone Resistance | Pass | — | IEC 60811-403 |

| Tensile Strength (at Break) | 9.5 | N/mm² | IEC 60811-501 |

| Permanent Elongation (After Cooling) | 0 | % | IEC 60811-507 |

| Tensile Strength (After Thermal Aging: 7 Days at 135°C) | 20 | % Variation | IEC 60811-401 UL 1581 & UL 2556 |

| Value | Units | Test Method / Conditions | |

| Density | 0.9 | g/cm³ | ASTM D792 BS EN ISO 1183-3 |

| Value | Units | Test Method / Conditions | |

| Permittivity (50Hz at 23°C) | 2.29 | — | IEC 60250 |

| Power Factor (50Hz at 23°C) | 0.0016 | — | IEC 60250 |

| Volume Resistivity (at 20°C) | min. 1 x 10¹⁶ | Ohm.cm | BS EN 50395 |

Technical Details & Test Data

- Processing

Extruder - Most modern thermoplastic extruders will process this compound, PE and PVC screws have showed very good results.

Extruder Temperature Conditions - It is important that the melt temperature is not allowed to increase above 205oC. As a guide the following temperature profile is recommended:Zone #1 Zone #2 Zone #3 Zone #4 Head Die Celsius 150°C 160°C 170°C 180°C 190°C 200°C Fahrenheit 302°F 320°F 338°F 356°F 374°F 392°F This profile will vary slightly depending on extruder type, head design and output. Initial purging of the extruder should be performed without the addition of catalyst masterbatch to reduce risks of precuring.

Screw Water Temperature – Not mandatory, if present we recommend 50-60°C

Recommended Screen Pack - 30, 50 mesh (mesh aperture per linear inch) or 600,300 micronHead & Tool Design - The head and tools should be so designed as to allow streamlined flow without the possibility of stagnation of material (where pre-curing could take place). To obtain the optimum in physical properties in the case of tubing tools, it is generally recommended that a draw down ratio not greater than 3.5 is used.

Crosslinking or Cure - A fast cure can be obtained either by immersion in hot water or exposure to low pressure steam at a temperature up to 70°C.

Catalyst & Color Masterbatch - The choice of catalyst will be based on conductor size, processing conditions and equipment; our technical team can assist with this choice. Addition of approved color masterbatches, including black, up to a maximum of 1%, has no detrimental effect on the properties or crosslinking capability. It is recommended that all masterbatches, including those containing the catalyst, should be thoroughly dried at 60°C for 8 hours or at 80°C for 4 hours.

Packaging & Availability

- Packaging

The following possibilities are available:

- Moisture resistant sacks containing 25kg

- Boxes with a moisture-resistant heat sealed liner containing 500kg

Storage & Handling

- Storage & Shelf Life

A period of at least 6 months from date of manufacture can normally be expected. The following storage conditions are recommended:

- Packaging should remain sealed

- Avoid temperature above 30C

- Avoid storage outside and in direct sunlight

- Use within 8 hours of opening packaging