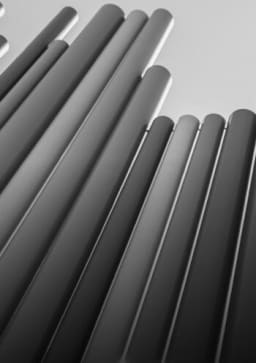

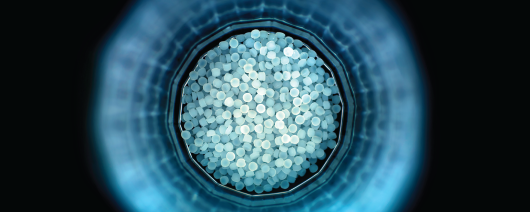

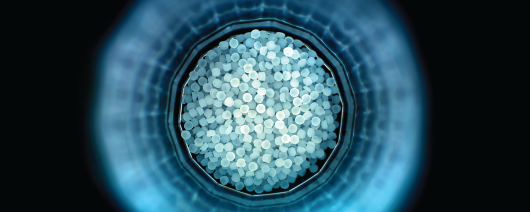

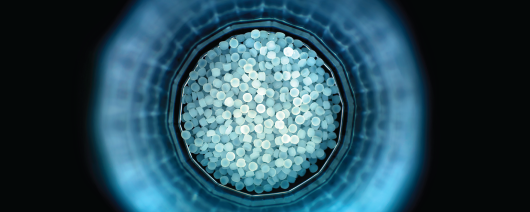

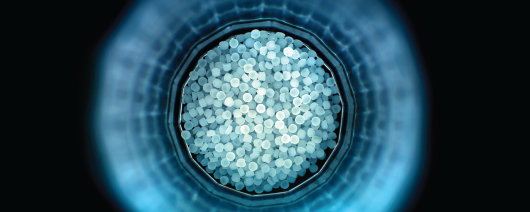

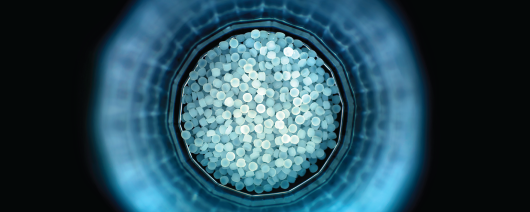

Our Sioplas-type moisture-crosslinkable polyolefins are available for a wide variety of end-use applications. Leading the market for two decades, our PEXIDAN® compounds feature outstanding longterm performance with superior strength, toughness, and resistance to heat, chemicals, abrasion and creep. PEXIDAN® compounds offer the best of crosslinked olefins with the ease of processing found in thermoplastics. PEXIDAN® compounds are well-suited for most processing techniques and post-curable by steam, hot water or even ambient means. Our Sioplas-type moisture-crosslinkable polyolefins are available for silane-PEX Pipe, Injection Molded Fittings and a variety of other end-use applications. Leading the market for more than three decades, our PEXIDAN® compounds feature outstanding long term performance with superior strength, toughness, and resistance to heat, chemicals, abrasion and creep. PEXIDAN® compounds offer the best of crosslinked olefins with the ease of processing found in thermoplastics. PEXIDAN® compounds are well-suited for most processing techniques and are post-curable by steam and hot water.