Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Features

- Low melting point

- Excellent dispersibility into PE

- Excellent heat sealability (Low melting point)y

Applications & Uses

- Markets

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Appearance

- Pale Yellow Pellet

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melting Point | approx. 115 | °C | — |

| Adapted Thermoplastic Resins | PE blown film PE, PP extrusion sheet | — | — |

| Surface Resistivity (23°C 73°F, 50% R.H) | 5×10^7 | — | — |

| Melt Flow Rate (190°C (374°F), 21.18 N) | approx. 15 | g/10min | — |

| Thermal Degradation Temperature | approx. 250 | °C | — |

Technical Details & Test Data

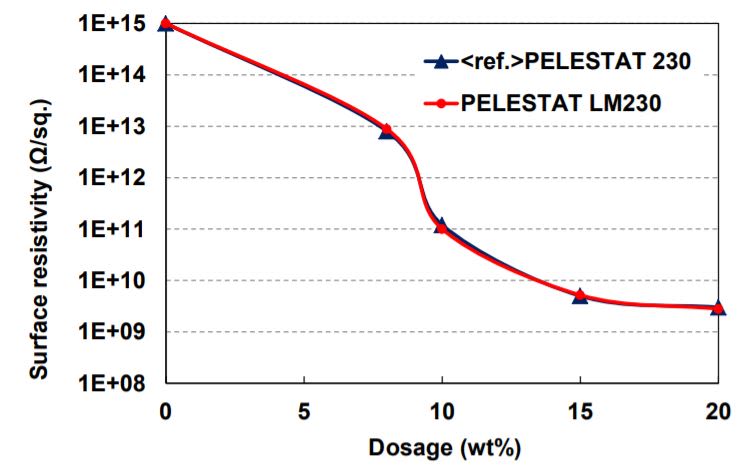

- LDPE BLOWN FILM EXTRUSION

Dosage (wt%)

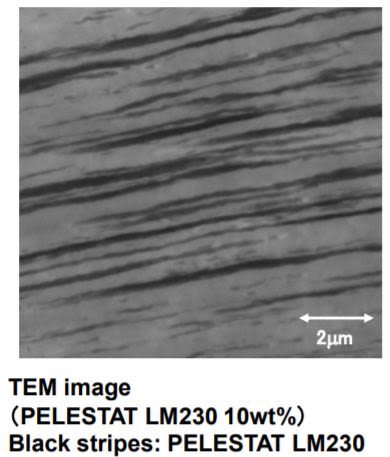

TEM image (PELESTAT LM230 10wt%) Black stripes: PELESTAT LM230

<Matrix resin:>

LDPE① [MFR=0.3 g/10min]

<Extrusion and blown film conditions>

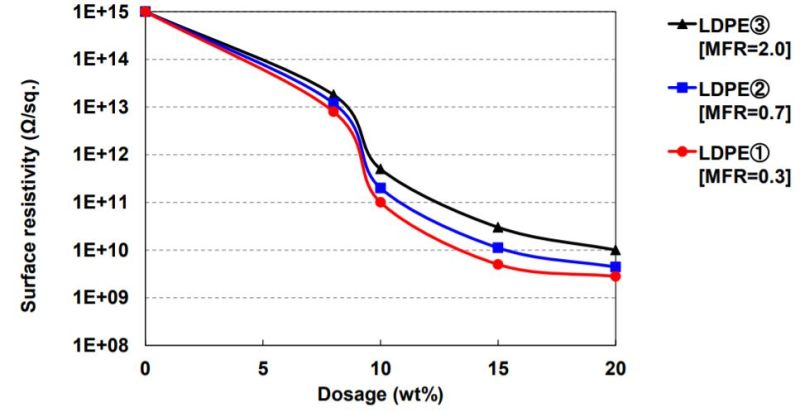

Temp.:170℃(338 °F) , Filmthickness: 50 mm, Blow rate:2- Effect of MFR(LDPE) on Surface resistivity

<Extrusion and blown film conditions>

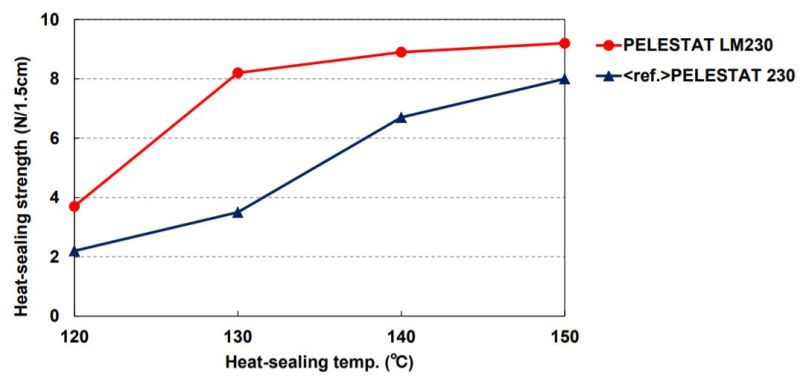

Temp.:170℃ (338 °F), Filmthickness:50 mm, Blow rate:2- Temperature dependence on heat-sealing Strength

Heat-sealing temp. (℃)

Composition

LDPE①/PELESTAT LM230/Metallocene PE=65 /15 /20 (wt%)

Extrusion and blown film conditions

Temp.:170℃(338 °F) , Filmthickness: 50 mm, Blow rate:2

Heat-sealing conditions

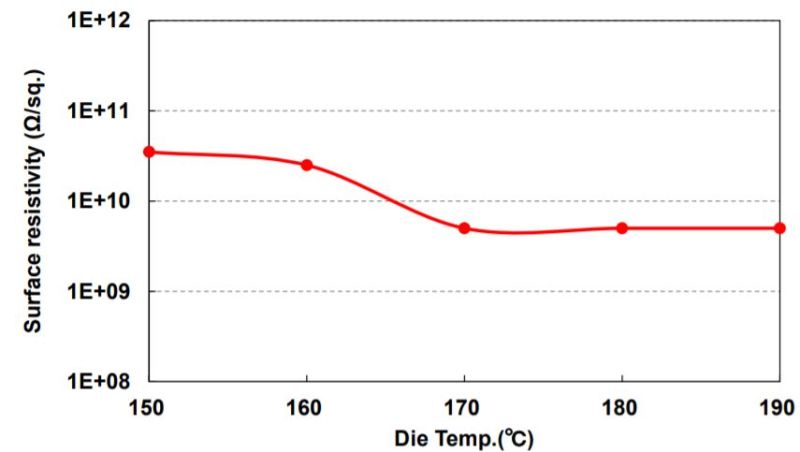

Both sides, Time:1 sec, Pressure:98 kPa- Effect of die temp on surface resistivity (Blown film)

Die Temp.(℃)

<Composition>

LDPE① /PELESTAT LM230

=85/15(wt%)

<Extrusion and blown film conditions>

Temp.:170℃ (338 °F), Filmthickness:50~100 mm- Physical properties(Blown film)

Property (Units) Test Method Dosage (wt %) LDPE

blankPELESTAT

LM2300 15 wt% Surface resistivity*1 (Ω/sq.) ASTM D257 10^16 10^10 Tensil Strength*2 (MPa) ASTM D638 24 19 Fracture elongation (%) ASTM D638 530 400 Haze (%) JIS K 7105 7 14 Total light transmittance JIS K 7105 91 89 *1 : 23℃ (73 °F), 50% R.H

<Extrusion and film conditions>

Temp.:170℃ (338 °F), Filmthickness:100 mm, Blow rate: 2- Polyethylene Resin used in the Evaluation

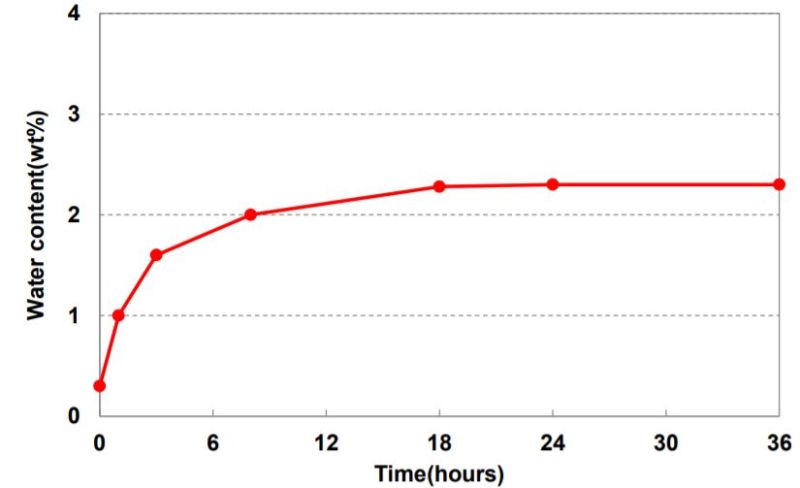

PE resin Supplier Grade MFR [190℃(374 °F) ,21.18 N] LDPE① Japan Polyethylene Co. LF128 0.3 LDPE② UBE-MARUZEN POLYETHYLENE Co. F022 0.7 LDPE③ UBE-MARUZEN POLYETHYLENE Co. F222 2.0 Metallocene PE Japan Polyethylene Co. KERNEL KS340T 3.5 - Hygroscopic Properties of PELESTAT LM230

Time(hours)

<Testing conditions>

23 ℃ (73 °F)

50% R.H.<Example of drying conditions >

Drying under reduced pressure

Vacuum : Below 1,300 Pa (0.2 psi)

Temperature : 70 – 80 ℃ (158 – 176 °F)

Duration : 2 – 3 hoursHot-air drying

Temperature: 85 – 95 ℃ (185 – 203 °F)

Duration: 4 – 6 hours