Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Technologies

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- Benifits of High-Purity Aluminas

- CATALOX products are the trademarks for the aluminum oxides derived from the controlled activation of CATAPAL products high-purity alumina hydrates.

- CATAPAL products are the respective trademarks of synthetic, high-purity boehmite (AlOOH) and bayerite (Al(OH)3), manufactured in Brunsbüttel, Germany, and Lake Charles, USA.

- The proprietary process used in the preparation of these high-purity aluminum oxides allows Sasol to control many important physical properties and hence “tailor-make” a product for your needs.

- CATALOX products are available as white, free-flowing powders with high purity and consistency. Due to the precisely controlled processing conditions during and after manufacturing these aluminum oxides, CATALOX products make excellent starting materials for the catalyst industry.

- CATALOX products provide excellent specific catalytic activities, high surface area stability, and low attrition loss.

- CATALOX products are arguably the best starting materials for the catalyst industry where consistency and a stable nature of the support is highly desired.

- These characteristics are of great importance for fluid and slurry bed applications. Due to their high thermal stability, CATALOX products are widely used raw materials for wash coat formulations in environmental emission-control catalysts.

- Recent developments have found other suitable uses for these materials in applications outside catalysis such as polishing, chromatography, adsorbents and gas separation.

Applications & Uses

- Markets

- Applicable Processes

- Base Chemicals End Uses

- PURALOX and CATALOX for Fluid Bed Application

The unique ability of Sasol to adjust certain physical properties makes the aluminas perfect for a variety of applications. For example, fluid-bed applications demand for rather coarse aluminas that also exhibit a high level of attrition resistance.

Technical Details & Test Data

- Analytical Methods

- Element Analysis: Alumina powder is quantitatively brought into solution by using acids and then analyzed by ICP, atomic emission. Additionally, X-ray fluorescence spectroscopy is used.

- Crystallite Type and Average Crystalline Phases: Powdered samples of the alumina are analyzed by using X-Ray Diffractometry (XRD) on either a Siemens D5000 or a Philips X’Pert diffractometer. The resulting diffractogram enables the laboratory to identify the crystal structure of the material.

- Particle Size Distribution: The particle size distribution of alumina may be measured by various instruments, namely, Cilas Granulometer 1064 supplied by Quantachrome, Malvern Mastersizer or Luftstrahlsieb (air sieve) supplied by Alpine.

- Surface Area Analysis: The surface area of the alumina is measured by using an instrument supplied by Quantachrome (Nova series) or by Micromeritics (Gemini series). The method entails low temperature adsorption of nitrogen at the BET region of the adsorption isotherm.

- Pore Volume and Pore Size Distribution: The boehmite is first calcined at 550 °C for three hours in preparation for analysis. The porosity is measured by nitrogen desorption using Autosorb instruments supplied by Quantachrome.

- Differential Scanning Calorimetry (DSC): Netzsch STA 449C Jupiter, Setaram 92 or Perkin Elmer instruments may be used with a selected heating rate to obtain the exothermic and endothermic transitions of alumina. Additional test methods are available for other physical properties upon request.

- Alumina Production Process

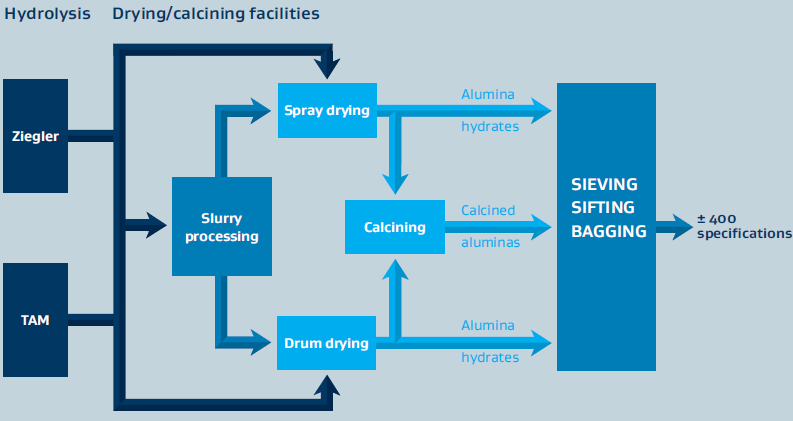

Sasol Inorganics produces high- and ultra-high-purity aluminas primarily through synthetic aluminum alkoxide processing routes. The alumina is produced either as a co-product with synthetic linear alcohols (Ziegler method) or directly from aluminum metal (on-purpose route). Several production steps must be completed to produce the different alumina-based products. In the first step, an aqueous intermediate (alumina slurry) is produced, which is further tailored in the subsequent processing steps to obtain the various products sold on the market. These can be alumina hydrates, calcined aluminas, and doped versions thereof.

Figure 1: Schematic for the Alumina Manufacturing Process

- Particle Size Distribution of PURALOX and CATALOX Aluminas

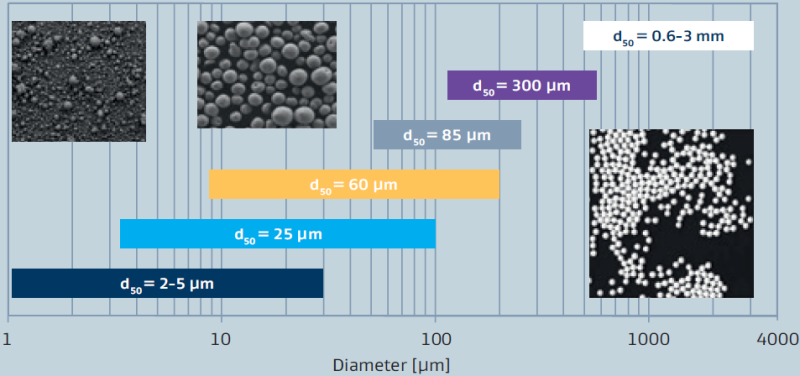

Unlike other alumina manufacturing processes which use less pure bauxite derivatives as a starting material, Sasol has pioneered a process based on aluminum alkoxide which produces synthetic alumina hydrates of high purity. Examples of some trace impurities are shown in table 1. Sasol produces aluminum oxides with a wide range of possible particle size distributions (figure 2). The range of possible average particle sizes stretches from 8 micrometers to 2.5 millimeters. Other pore size distributions are available on request.

Dry-milled versions of our alumina are available under the tradename PURALOX UF and CATALOX UF as well. These ultra-fine materials comprise mean particle sizes in the range of typically 2–6 μm, which can be tailored upon customer request. Ultra high-purity grade (PURALOX UHPA) is available upon request.

Fig 2: Areas of the particle size distribution of PURALOX and CATALOX aluminas

Table 1: Chemical purity of PURALOX and CATALOX Aluminas

Impurity ppm (typical) Na2O <20 Fe2O3 50–100 SiO2 50–120 Table 2: Purity of PURALOX UHPA Aluminas

Impurity ppm (typical) Na2O 1 Fe2O3 3 SiO2 3 - Calcination

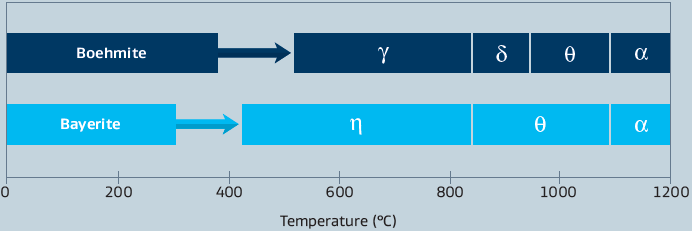

- The final crystalline phase and physical properties of the alumina depend on the physical properties of the starting material as well as the calcination process. Our calcined aluminas are predominantly based on high-purity boehmite as the starting alumina hydrate.

- Typical calcination temperatures of the boehmite lie within 600-1000°C. Applying such temperatures, the physically and chemically bound water is removed, transforming the hydrate into an oxide. High temperature calcination leading to α-Alumina can also be applied.

Figure 4: Sequence of phase transistions

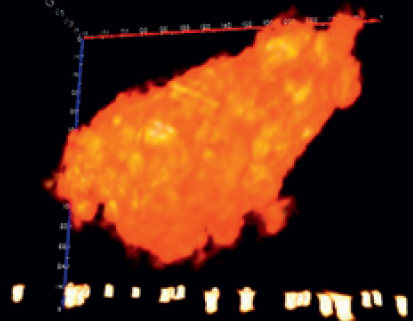

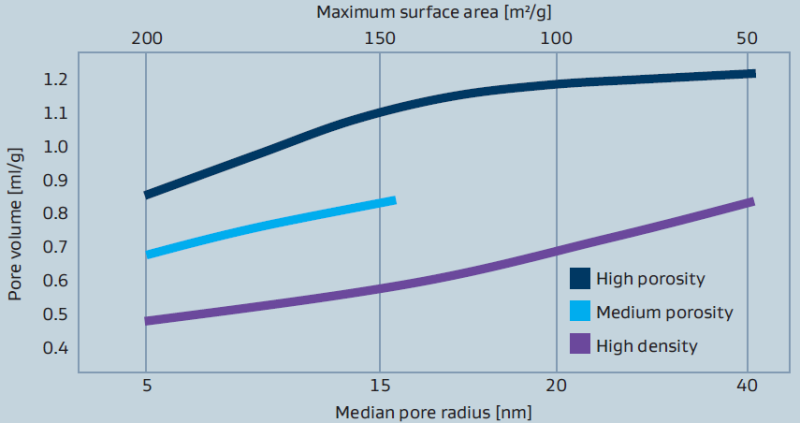

- Thy physical properties of the aluminum oxides are to a large extend adjusted at the stage of the corresponding hydrates by varying their crystallite size and shape. This way, aluminas with tailored porosities are accessible, ranging from high-density to high-porosity materials. These two border cases are illustrated in Figure 5.

Figure 5a: Electron tomography of high-density aluminas showing different crystallite arrangements.

Figure 5a: Electron tomography of high-porosity aluminas showing different crystallite arrangements.

- Properties such as the crystalline phase, surface area and porosity can be altered significantly by varying the calcination process. Figure 6 shows a graphic representation of the relationship between the surface area, pore volume and average pore radius. Depending on the physical characteristics of the initial alumina hydrate Sasol is able to prepare aluminum oxides with various pore volumes.

Figure 6: Alumina grades with different porosities

- Doped Aluminas Analysis

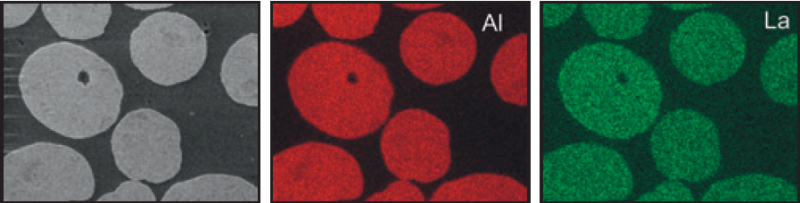

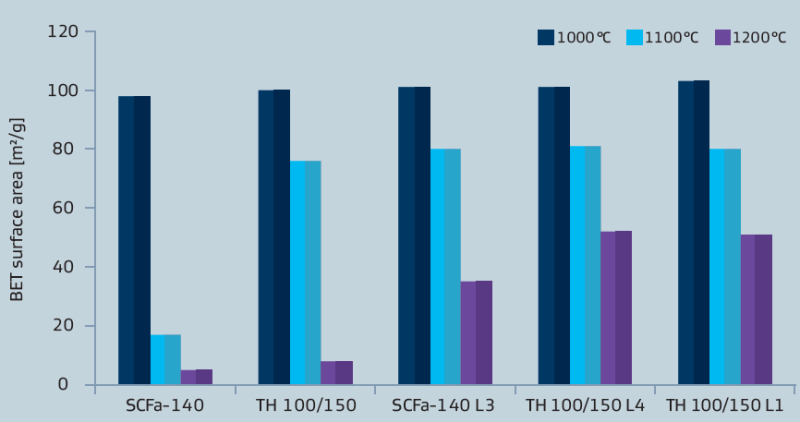

Sasol aluminas are also available as doped or even multi-doped versions (e.g. La, Ce, Ti, Zr). The resulting interplay of well-defined physical properties and chemical modifications is a further step towards optimized support materials for various applications like emission control or refinery catalysts. As an example, the addition of lanthanum-oxide improves the thermostability of the base alumina as it can be seen in figure 8.

Figure 7: SEM-EDX illustration of a La-doped alumina

Figure 8: Thermostability of pure, La- and Ba-doped aluminas

Storage & Handling

- Storage & Handling Information

CATALOX aluminas are dry, pure aluminum oxides, however, since all aluminas adsorb atmospheric moisture, facilities should be designed to avoid excessive exposure to moist air. By excluding moisture from the storage of alumina, shelf life is extended.CATALOX are abrasive materials. Therefore, handling and storage equipment should be abrasion-resistant carbon steel, aluminum, or polypropylene-lined steel.