Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Technologies

Features & Benefits

- Base Chemicals Features

- CASE Ingredients Features

- Product Highlights

The unique product characteristics of Sasol dispersible boehmites can lead to many advantages for use in different systems. Some key features are:

- The high purity boehmites are produced under careful control to yield products with consistent quality and reliable performance.

- The powders are highly dispersible. Low-viscosity nano-sized particle sols can be prepared at room temperature in 10 to 30 minutes with concentrations of 10-40 wt.% AlOOH.

- The boehmites are versatile. They can be employed under a variety of application conditions, including low or high pH and low or high shear.

- Sasol also offers boehmites which are dispersible in polar and non-polar organic media.

- Product Advantages

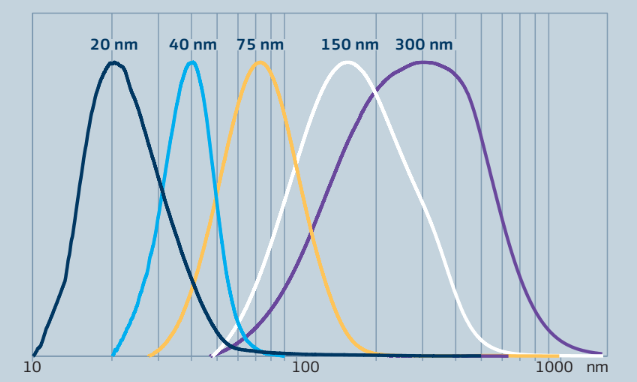

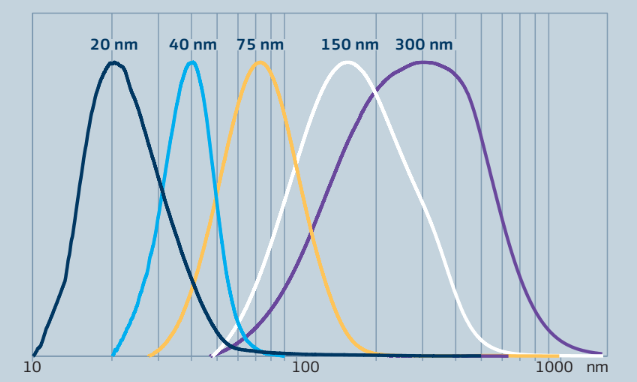

Sasol pioneered processes utilizing alkoxide chemistry to convert primary aluminium metal into synthetic boehmite of exceptional purity. Unlike other alumina manufacturing processes that start with less pure materials, Sasol’s processes yield aluminas with significantly lower levels of common impurities such as iron, sodium and silica (table 1). Additionally, our 50 years of experience, in combination with other proprietary production techniques, allow us to produce highly dispersible boehmites with a wide range of physical properties such as dispersed particle size (figure 2) resulting in translucent to opaque dispersions (figure 1). Thus, our customers are not limited in their thinking for possible uses for the aluminas.

Impurity ppm (typical) Na₂O <20 Fe₂O₃ 50-100 SiO₂ 50-120 Table 1: Chemical purity of DISPERAL boehmite powders

Figure 1: Translucent to opaque boehmite sols, each with a concentration of 10 wt.% AlOOH

Figure 2: Dispersed particle size distributions of selected products

Applications & Uses

- Markets

- Applications

- Base Chemicals End Uses

Properties

- Physico-Chemical Properties

- Note

Chemical purity: C: 0.25 %, SiO2: 0.01-0.015 %, Fe2O3: 0.005-0.015 %, TiO2: 0.01-0.15 %

- * Particle size as measured on the powder

- ** After activation at 550°C for 3 hours

To form a colloidal sol or dispersion simply stir the powder in deionized water with moderate agitation at room temperature for 10-20 minutes

| Value | Units | Test Method / Conditions | |

| Aluminium Oxide (Al₂O₃) | 72.0 | % | — |

| Sodium Oxide (Na₂O) | 0.002 | % | — |

| Nitrate (NO₃) | 4.0 | % | — |

| Loose Bulk Density | 850.0 | g/l | — |

| Particle Size (d50)* | 45.0 | μm | — |

| Surface Area (BET)** | 260.0 | m²/g | — |

| Pore Volume** | 0.5 | ml/g | — |

| Crystallite Size (120) | 4.5 | nm | — |

| Dispersed Particle Size | 25.0 | nm | — |

| Water Dispersibility | 97.0 | % | — |

Technical Details & Test Data

- Dispersing Procedure

How to Disperse and Use DISPERAL

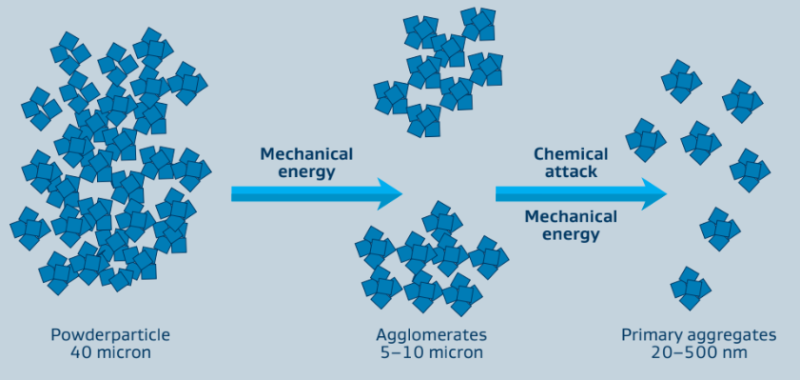

DISPERAL powders may be dispersed by following the descriptions below. Figure 3 shows a schematic representation of what occurs to the powder during dispersion using chemical attack and mechanical energy.

Figure 3: Schematic mechanism of dispersion

Water Dispersible Boehmite

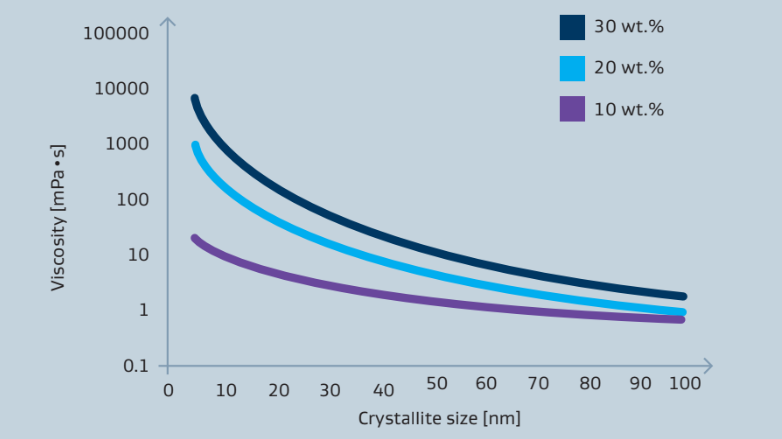

To form a colloidal sol or dispersion from a water dispersible DISPERAL, simply stir the powder in deionized water with moderate to intense agitation at room temperature for 20-30 minutes. The maximum achievable solids loading will vary according to the specific boehmite selected (figure 4). For most applications, the boehmites perform best when completely dispersed prior to further formulation. The resulting pH will be between 3 and 5.

Figure 4: Schematic mechanism of dispersion

- Rheology

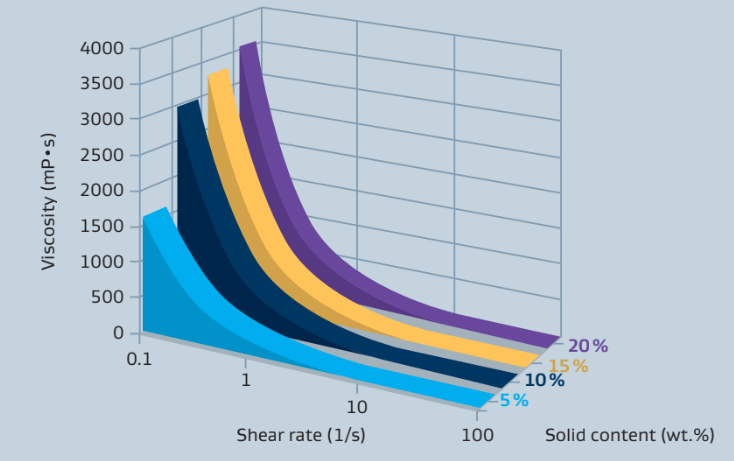

Rheological characteristics of boehmite dispersions can be affected by numerous factors. These include product used, solid content, crystallinity, water quality, pH, ionic strength and other formulation components. Figure 4 gives example curves of viscosity versus crystallite size for some typical Sasol products. Also low-viscosity dispersions can be “thickened” by the addition of acids, bases or salts to form thixotropic, shear-thinning systems (figure 5). This, for example, allows boehmite to function as a thickener for many types of either acidic or basic formulations.

Figure 5: Effect of boehmite concentration on viscosity versus shear rate

- Analytical Methods

- Crystallite size - Crystallite plane dimensions in powdered alumina samples are analyzed using X-ray diffraction techniques on X-ray diffractometers supplied by Siemens or Philips.

- Dispersed particle size - The particle size distribution of diluted alumina sols and dispersions is measured using laser diffraction or photon correlation spectroscopy techniques on Malvern or Cilas instruments.

- Dispersibility of alumina powder - A specified amount of alumina powder is added to water or dilute acid under stirring. The mixture is then stirred for a specified period of time to form a dispersion. The dispersion is centrifuged, and the undispersed residue is isolated, dried, and weighed to determine the percent non-dispersed material.

- Surface area - The boehmite aluminas are first calcined at 550°C for three hours in preparation for analysis. Alumina surface area is then measured using BET nitrogen adsorption techniques on instruments supplied by Quantachrome (Nova series) or by Micromeritics (Gemini series).

- Trace element analysis - Trace element analysis is performed by using several methods, including X-ray fluorescence of pressed alumina disks and wet techniques (ICP/OES).

Safety & Health

- Safety Information

DISPERAL boehmite powders are classified as non-toxic nuisance dusts. Exposure to high concentrations of dust may cause physical irritation and drying of skin and eye tissues. Repeated or prolonged contact with alumina sols may cause irritation as well. Handling and shipping procedures should be designed to avoid such contact and to minimize the inhalation of airborne dust. Normal good laboratory practices and operating procedures should ensure personnel safety.

Storage & Handling

- Storage and Transfer Conditions

Sasol pioneered processes utilizing alkoxide chemistry to convert primary aluminum metal into synthetic boehmite of exceptional purity. Unlike other alumina manufacturing processes that start with less pure materials, Sasol’s processes yield aluminas with significantly lower levels of common impurities such as iron, sodium and silica (table 1). Additionally, our 50 years of experience, in combination with other proprietary production techniques, allow us to produce highly dispersible boehmites with a wide range of physical properties such as dispersed particle size (figure 2) resulting in translucent to opaque dispersions (figure 1). Thus, our customers are not limited in their thinking for possible uses for the aluminas.

Impurity ppm (typical) Na₂O <20 Fe₂O₃ 50-100 SiO₂ 50-120 Table 1: Chemical purity of DISPERAL boehmite powders

Figure 1: Translucent to opaque boehmite sols, each with a concentration of 10 wt.% AlOOH

Figure 2: Dispersed particle size distributions of selected products