Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Applicable Processes

Properties

- Physico-Chemical Properties

- Note

Chemical purity: C: 0.25 %, SiO2: 0.01-0.015 %, Fe2O3: 0.005-0.015 %, TiO2: 0.01-0.20 %

- *After activation at 550°C for 3 hours

| Value | Units | Test Method / Conditions | |

| Aluminium Oxide (Al₂O₃) | 74.0 | % | — |

| Sodium Oxide (Na₂O) | 0.002 | % | — |

| Loose Bulk Density | 600 - 850 | g/l | — |

| Packed Bulk Density | 800 - 1100 | g/l | — |

| Particle Size (d50) | 45.0 | μm | — |

| Surface Area (BET)* | 250.0 | m²/g | — |

| Pore Volume* | 0.5 | ml/g | — |

| Crystallite Size (120) | 5.0 | nm | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Advantages of PURAL Alumina Hydrates

- PURAL alumina hydrates are mildly abrasive materials with a Mohs hardness of 3.5 to 4.0. Therefore, handling and storage equipment should be abrasion resistant carbon steel, aluminum or polypropylene-lined steel are recommended.

- Blower or vacuum systems are typically used to move the product. A minimum of 4,000 ft/ min fluidizing velocity is recommended. Since alumina will adsorb atmospheric moisture facilities should be designed to avoid moist air contact with alumina.

- Extrusion Behavior

Extrusion is a key use for these types of alumina hydrates due to their ability to form excellent extruded supports. This application takes advantage of the ability to peptize in the presence of organic/inorganic acids.

A wide variety of extrudate properties can be obtained by using different grades of PURAL and by controlling the formulation and extrusion variables. Optimum formulations depend on the exact choice of mixer, extruder and powder properties. General extrusion guidelines can be recommended by our technical staff.

Our unique ability to adjust the peptization behavior means that the gelling behavior of PURAL can be modified to supply a product optimized for our customers’ own unique set of processing conditions. Nitric acid gelation time (NAG) is a valuable tool for selecting the right material for your processing conditions.

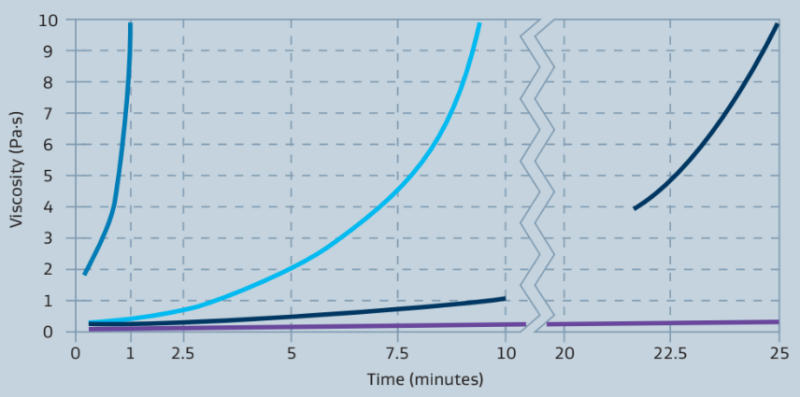

NAG is the time required for a concentrated dispersion of boehmite to reach a certain viscosity by peptization. This behavior is shown in figure 6 and illustrates the range of NAGs we are able to produce on our customers’ request. The graph is not meant to indicate the only NAGs available.

Figure 5: Viscosity behavior of boehmite dispersions having different NAG values

- Calcination

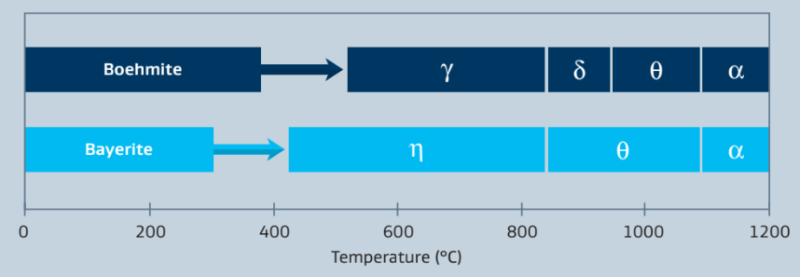

The final crystalline phase and physical properties of calcined aluminas depend on the initial crystalline properties of the starting alumina hydrate as well as the calcination temperature. The sequence of phase transitions of boehmite and bayerite are shown in figure 6. Physical properties such as crystalline phase, surface area and porosity can be altered significantly by varying the calcining time and temperature. Applied temperatures are typically between 600°C and 1,000°C. This process results in the loss of physisorbed and crystal water.

Figure 6: Sequence of phase transitions

- Analytical Methods

- Trace Element Analysis - Alumina hydrate powder is quantitatively brought into solution by using acids and then analyzed by ICP, atomic emission. Additionally, X-ray fluorescence spectroscopy is used.

- Crystallite Type and Average Crystal Size - Powdered samples of the alumina are analyzed by using X-Ray Diffractometry (XRD) on either a Siemens D5000 or a Philips X’Pert diffractometer. The resulting diffractogram enables the laboratory to identify the crystal structure of the material.

- Particle Size Distribution - The particle size distribution of alumina may be measured by various instruments, namely, Cilas Granulometer 1064 supplied by Quantachrome, Malvern Mastersizer or Luftstrahlsieb (air sieve) supplied by Alpine.

- Surface Area Analysis* - The surface area of PURAL and CATAPAL is measured by using an instrument supplied by Quantachrome (Nova series) or by Micromeritics (Gemini series). The method entails nitrogen adsorption at the BET region of the adsorption isotherm.

- Pore Volume and Pore Size Distribution - The boehmite is first calcined at 550°C for three hours in preparation for analysis. The porosity is measured by nitrogen desorption using Autosorb instruments supplied by Quantachrome.

- Differential Scanning Calorimetry (DSC) - Netzsch STA 449C Jupiter, Setaram 92 or Perkin Elmer instruments may be used with a selected heating rate to obtain the exothermic and endothermic transitions of alumina. Additional test methods are available for other physical properties upon request.

- Nitric Acid Gelation (NAG) - 200 g of powder is dispersed in 234,5 g of distilled water and is then stirred for exactly 3 minutes. 98 ml of 3.93 % nitric acid is then quickly added under stirring to create a 37.5 weight % dispersion. The viscosity of the dispersion is then measured. The NAG value is defined as the time required for the dispersion to gel to 9,500 mPa·s from the time that the acid is added. Additional test methods are available for other physical properties upon request.

* After alumina activation at 550°C for 3 hours.

Safety & Health

- Safety Information

- PURAL are classified as a non-toxic, nuisance dust. Exposure to high concentrations of dust may cause physical irritation.

- Repeated or prolonged contact with skin may result in drying and irritation. Handling procedures should be designed to minimize inhalation and skin exposure. Normal good housekeeping and operating procedures should ensure personnel safety. See also corresponding material data safety sheet.

Storage & Handling

- Storage and Transfer Conditions

- PURAL alumina hydrates are mildly abrasive materials with a Mohs hardness of 3.5 to 4.0. Therefore, handling and storage equipment should be abrasion resistant carbon steel, aluminium or polypropylene-lined steel are recommended.

- Blower or vacuum systems are typically used to move the product. A minimum of 4,000 ft/ min fluidizing velocity is recommended. Since alumina will adsorb atmospheric moisture facilities should be designed to avoid moist air contact with alumina.