Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- At The Core

- Advanced FDM Technology FDM (fused deposition modeling) technology works with engineering-grade thermoplastics to build strong, longlasting and dimensionally stable parts with the best accuracy and repeatability of any 3D printing technology. These parts are tough enough to be used as advanced conceptual models, functional prototypes, manufacturing tools and production parts.

- Meet production demands FDM systems are as versatile and durable as the parts they produce. Advanced FDM 3D Printers boast the largest build envelopes and material capacities in their class, delivering longer, uninterrupted build times, bigger parts and higher quantities than other additive manufacturing systems, delivering high throughput, duty cycles and utilization rates.

- Opening the way for new possibilities FDM 3D Printers streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. Industries can cut lead times and costs, products turn out better and get to market faster.

- No special facilities needed FDM 3D Printers are easy to operate and maintain compared to other additive fabrication systems because there are no messy powders or resins to handle and contain, and no special venting is required because FDM systems don’t produce noxious fumes, chemicals or waste.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color

- Physical Form

- Physical Properties

- Mechanical Properties

| Value | Units | Test Method / Conditions | |

| HDT (66 psi) | 150 | °C | ASTM D648 Method B |

| HDT (264 psi) | 153 | °C | ASTM D648 Method B |

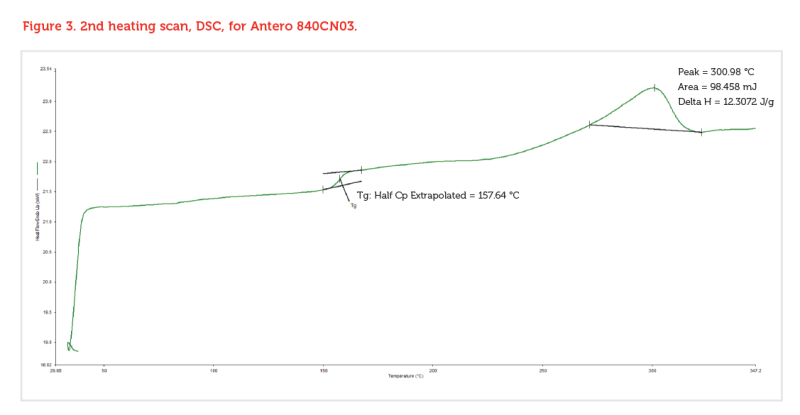

| Tg | 158 | °C | ASTM D7426 Infl ection Point |

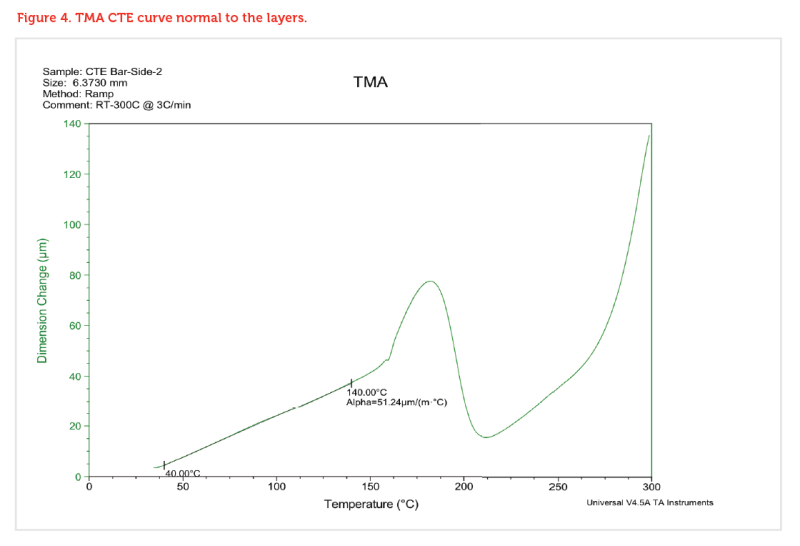

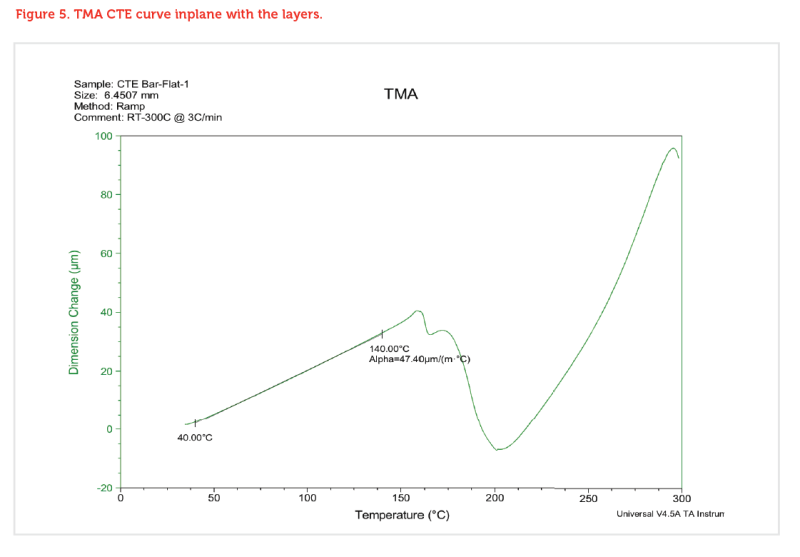

| Mean CTE | 50 | μm/[m·°C] | ASTM E831 (40 °C to 140 °C) |

| Volume Resistance | 104-109 | Ohms-cm | ASTM D257 |

| Specifi c Gravity | 1.27 | — | ASTM D792 @ 23 °C |

| Value | Units | Test Method / Conditions | |

| Tensile Properties Yield Strength (XZ Orientation) | 65 | MPa | ASTM D638 |

| Flexural Properties Strain at Break (XZ Orientation) | No break | % | ASTM D790 |

| Tensile Properties Elongation (Yield,XZ Orientation) | 4.4 | % | ASTM D638 |

| Flexural Properties Strain at Break (ZX Orientation) | 2.4 | % | ASTM D790 |

| Tensile Properties Strength (Break,XZ Orientation) | 95 | MPa | ASTM D638 |

| Tensile Properties Elongation (Break,XZ Orientation) | 6 | % | ASTM D638 |

| Tensile Properties Modulus (Elastic) (XZ Orientation) | 3.17 | GPa | ASTM D638 |

| Flexural Properties Strength (XZ Orientation) | No break | MPa | ASTM D790 |

| Flexural Properties Strength (5% Strain) (XZ Orientation) | 135 | MPa | ASTM D790 |

| Flexural Properties Modulus (XZ Orientation) | 3.24 | GPa | ASTM D790 |

| Compression Properties Yield Strength (XZ Orientation) | 100 | MPa | ASTM D695 |

| Compression Properties Modulus (XZ Orientation) | 2.61 | GPa | ASTM D695 |

| Impact Properties Izod (Notched,XZ Orientation) | 48 | J/m | ASTM D256 |

| Impact Properties Izod (UNnotched, XZ Orientation) | 1470 | J/m | ASTM D4812 |

| Tensile Properties Yield Strength (ZX Orientation) | No yield | MPa | ASTM D638 |

| Tensile Properties Elongation (Yield,ZX Orientation) | No yield | % | ASTM D638 |

| Tensile Properties Strength (Break,ZX Orientation) | 50 | MPa | ASTM D638 |

| Tensile Properties Elongation (Break,ZX Orientation) | 1.8 | % | ASTM D638 |

| Tensile Properties Modulus (Elastic,ZX Orientation) | 3.01 | GPa | ASTM D638 |

| Flexural Properties Strength (ZX Orientation) | 70 | MPa | ASTM D790 |

| Flexural Properties Modulus (ZX Orientation) | 2.7 | GPa | ASTM D790 |

| Compression Properties Yield Strength (ZX Orientation) | 105 | MPa | ASTM D695 |

| Compression Properties Modulus (ZX Orientation) | 2.63 | GPa | ASTM D695 |

| Impact Properties Izod (Notched,ZX Orientation) | 28 | J/m | ASTM D256 |

| Impact Properties Izod (UNnotched, ZX Orientation) | 128 | J/m | ASTM D4812 |

Regulatory & Compliance

- Certifications

- ISO 9001:2015

- AS 9100:2016

- Controlled Goods Program

Technical Details & Test Data

- Ordering Information

3D Printer Compatibility

- F900™ T20D tip

- T16 tip (support only)

Support Material

SUP8000B™ breakaway support system (BASS)

Build Sheets

High temperature .02 x 16 x 18.5 in. (0.76 x 406 x 470 mm) .02 x 26 x 38 in. (0.76 x 660 x 965 mm)

Table 1. Antero 840CN03 Thermoplastic Filament Ordering Information

Part Number Description Filament Canisters 355-02510 Antero 840CN03, 92.3 cu in – Plus

355-03260 SUP8000B, 92.3 cu in – Plus

Printer Consumables 511-10730-S T20D tip, 0.010 in. (0.254 mm) layer height

511-10401 T16 tip, 0.010 in. (0.254 mm) layer height

325-00275-S High Temperature build sheet, 0.02 x 26 x 38 in (0.76 x 660 x 965 mm)

325-00475-S High Temperature build sheet, 0.02 x 16 x 18.5 in (0.76 x 406 x 470 mm)

- Test Results

Antero 840CN03 was tested for resistance to chemical exposure per ASTM D543. Chemicals tested and percent change from control is listed below. For further details read the Antero 840CN03 Chemical Resistance White Paper.

Table 4. Antero 840CN03 Thermoplastic Filament Chemical Resistance

Change in Mechanical Properties, Antero 840CN03 - 168 Hour Chemical Exposure (ASTM D543)

Tensile Strength

Reagent XZ Orientation ZX Orientation Dichloromethane -88% -74.80% Ethyl Acetate -2.90% -2.30% Jet A -2.10% 7.30% MEK -0.70% -2.10% Skydrol -2.10% 6.30% Toluene -5.00% 1.40% 30% Nitric Acid -5.70% 5.70% 30% Sulfuric Acid -9.30% -10.10% 60% Sodium Hydroxide -1.40% 1.90% Concentrated Ammonia -1.40% 11.00% Elongation At break(%)

Dichloromethane 714.80% 1598.40% Ethyl Acetate 4.20% 16.20% Jet A -0.40% 7.00% MEK -4.40% 11.90% Skydrol 32.30% 9.70% Toluene 17.20% 32.40% 30% Nitric Acid 61.40% 52.40% 30% Sulfuric Acid 47.20% -5.40% 60% Sodium Hydroxide 5.20% -1.60% Concentrated Ammonia 11.10% 10.80% Tensile Modulus

Dichloromethane -90.70% -85.30% Ethyl Acetate 1.80% 6.40% Jet A 1.40% 5.30% MEK 3.10% 4.30% Skydrol 0.60% 6.70% Toluene -0.40% 6.20% 30% Nitric Acid -0.80% -6.20% 30% Sulfuric Acid -7.60% -5.00% 60% Sodium Hydroxide 0.20% 3.30% Concentrated Ammonia -0.40% 5.00% Flame, Smoke, and Toxicity

Antero 840CN03 was printed With a T20D up on the Stratasys F900 and tested 14 CFR 25853. 7238 and 7238, and AITM and 3.(XXE. The done that this material, samples 0.040 thick otherwise noted, meets requirements for:

- 60s and 12s Vertical Burn

- 15s Horizontal Burn

- Toxic Gas Emission

- Smoke Density

- Heat Release Rate of Cabin Materials

Table 5. Antero 840CN03 Flame, Smoke, and Toxicity Test Results

Avg Time to Extinguish (seconds) Avg Burned Length (inches)

Drip Time to Extinguish (seconds) 12 Second Vertical Ignition per 14 CFR 25.853(a), Appendix F, Part I, Paragraph (a)(1)(ii) Antero 840CN03, Vertical - ZX 3.2 0.3 0 (no drips) Antero 840CN03, Horizontal - XZ 4.7 0.2 0 (no drips) 60 Second Vertical Ignition per 14 CFR 25.853(a), Appendix F, Part I, Paragraph (a)(1)(i) Antero 840CN03, Vertical - ZX <1 0.5 0 (no drips) Antero 840CN03, Horizontal - XZ <1 0.5 0 (no drips) 15 Second Horizontal Ignition per 14 CFR 25.853(a), Appendix F, Part I, Paragraph (a)(1)(iv)(v) Antero 840CN03, Vertical - ZX 0 Antero 840CN03, Horizontal - XZ 0 Test Mode Average DS (maximum) within 4 minutes, (4Dmax )

Smoke Density per BSS 7238, Rev. C Antero 840CN03, Vertical - ZX Flaming 0 Antero 840CN03, Horizontal - XZ Flaming 0 Smoke Density per AITM 2.0007B, Issue 3 Antero 840CN03, Vertical - ZX Flaming 0 Antero 840CN03, Horizontal - XZ Flaming 0 Antero 840CN03, Vertical - ZX Non-Flaming 0 Antero 840CN03, Horizontal - XZ Non-Flaming 0 Table 5. Antero 840CN03 Flame, Smoke, and Toxicity Test Results

Test Mode CO ppm SO2 ppm NOX ppm HCN ppm HCI ppm HF ppm Toxic Gas Emission per BSS 7239, Rev. A Antero 840CN03, Vertical - ZX Flaming 5 0 (NI) 0 (NI) 0 (NI) 0 (NI) 0 (NI) Antero 840CN03, Horizontal - XZ Flaming <5 0 (NI) 0 (NI) 0 (NI) 0 (NI) 0 (NI) Toxic Gas Emission per AITM 3.0005, Issue 2 Antero 840CN03, Vertical - ZX Flaming 4 0 0.1 0 (NI) 0 (NI) 0 (NI) Antero 840CN03, Horizontal - XZ Flaming 3 0 0.3 0 (NI) 0 (NI) 0 (NI) Antero 840CN03, Vertical - ZX Non-Flaming 0 0 0 0 (NI) 0 (NI) 0 (NI) Antero 840CN03, Horizontal - XZ Non-Flaming 1 0 0 0 (NI) 0 (NI) 0 (NI) Peak HRR (kW/m2) Time to Peak Heat Release (seconds) 2 Minute Total HRR (kW-min/m2)

Heat Release Rate of Cabin Materials per 14 CFR 25.853(d), Appendix F, Part IV(1) Antero 840CN03, Horizontal - XZ 55.9 286.7 0 Antero 840CN03, Vertical - ZX 55.1 293 0.1 Outgassing

Table 6. Antero 840CN03 Outgassing Test Results

Sample TML (%) CVCM (%) WVR (%) Vertical Build - ZX 0.41 <0.01 0.17 Horizontal Build - XZ 0.45 0.01 0.15 Testing Observations Visible Condensate Yes Opaque Yes Percent Covered 10% (ZX), 25% (XZ) Interference Fringes No Thin Yes Colored Fringes No Heavy No Sample Appearance After Test No change Transparent No - Test Data

Samples were printed with 0.010 in. (0.254 mm) layer height.

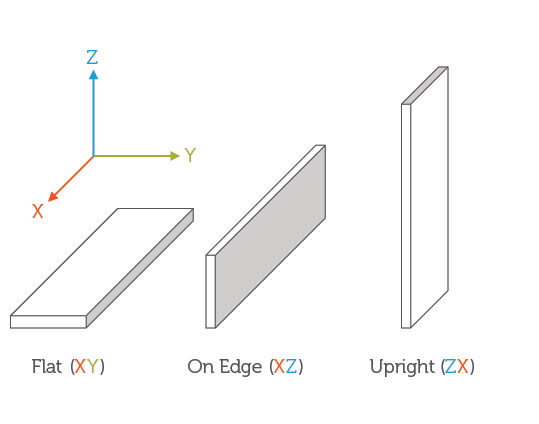

Print Orientation

Parts created using FDM are anisotropic as a result of the printing process. Below is a reference of the dierent orientations used to characterize the material.

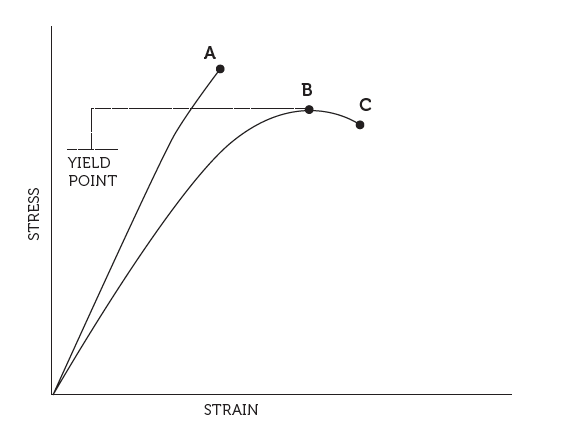

Tensile Curves

Due to the anisotropic nature of FDM, tensile curves look types of curves seen when printing tensile samples and what reported values mean. dierent dependingon orientation. Below is a guide of the two.

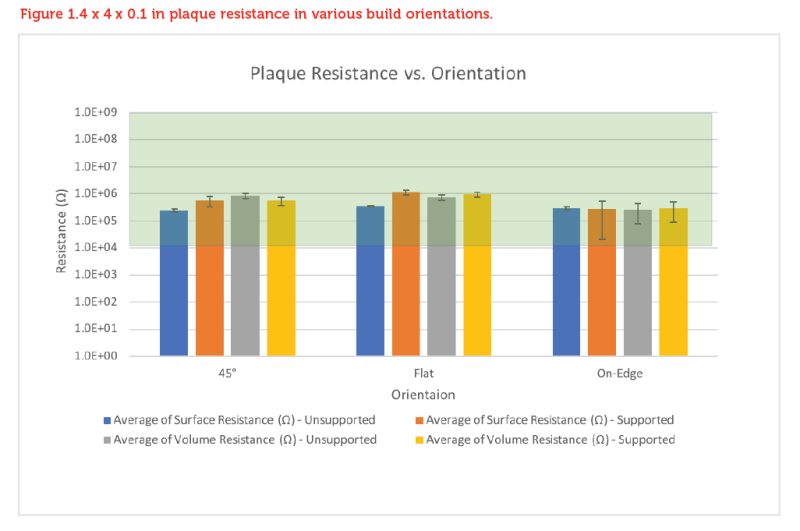

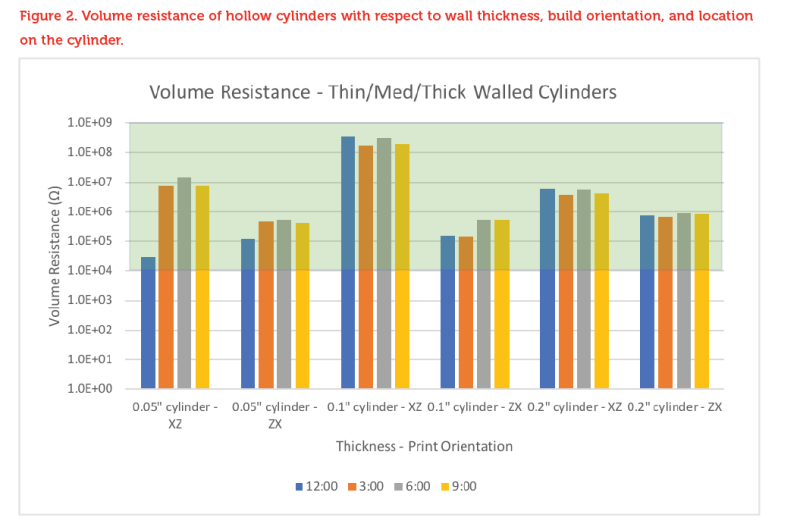

ESD Properties

Antero 840CN03 was tested per ANSI ESD S20.20, S11.11, STM11.12 to determine the eect that build parameters and part geometries had on ESD properties. Dierent geometries printed in dierent orientations all fall into the ESD safe range (104 to 109 ohms). For full details, see the Antero 840CN03 ESD White Paper.

Appendix