Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- INCI Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 1643-20-5

- EC No.

- 216-700-6

- Technologies

- Product Families

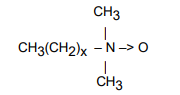

- Chemical Structure

x = 11 (predominantly)

Features & Benefits

- Benefit Claims

- Labeling Claims

- Agrochemicals Features

- Functional Properties

- Foam Enhancer

- Foam Stabilizer

- Viscosity Builder

- Lubricant*

- Bleach Stable

- Emulsifier*

- Wetting Agent*

- Dye Dispersant*

- Can be formulated with anionic, nonionic and cationic materials.

- Acid Stable

(*For the textile industry)

- Biodegradability

Product is readily biodegradable.

- Features

Preservative Free

Applications & Uses

- Applications

- Bath & Shower Applications

- Hair Care Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Personal Hygiene Applications

- Skin Care Applications

- End Product Uses

Personal Care

- Shampoos

- Handsoaps

- Bath Products

- Creams & Lotions

- Hair Conditioners

Household & I&I

- Dishwashing Detergents

- Cleansers

- Hard Surface Cleaners (which contain acids or bleach)

- Applications

- 2 in 1 Shampoo

- Automatic Dishwashing Detergents

- Bathroom Cleaners

- Body Wash

- Brewery Cleaners

- Carwash - Automatic

- Carwash - Hand

- Degreasers

- Facial Cleansers

- Fine Fabric Wash

- Floor Cleaners

- Hand Dishwashing Detergents

- Hand Soaps

- Hard Surface Cleaners - Dilutable

- Hard Surface Cleaners - Ready to Use

- Kitchen Cleaners

- Laundry Detergents

- Meat Packing Plant Cleaners

- Metalworking Cleaners

- Other Home Care

- Other Institutional and Industrial Cleaning

- Oven and Grill Cleaners

- Oven and Grill Cleaners

- Shampoos

- Soap Bars

- Soluble Liquids (SL)

- Tank Mix Adjuvants

- Textile Wet Processing

- Textile and Synthetic Fibers

- Toilet Bowl Cleaners

- Truck Wash

- Warewash Detergents

Properties

- Physical Form

- Appearance

- Clear liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Boiling Point | 100 | °C | — |

| Amine Oxide (EW 238) | 30 | % | — |

| Cloud Point | -1 | °C | — |

| Free Amine (EW 222) | max. 1 | % | — |

| Color | max. 100 | — | Apha Scale |

| pH (10% in aqueous solution) | 8 | — | — |

| Density | 0.968 | g/ml | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Freeze Point | -12 | °C | — |

| Free Peroxide | 0.13 | % | — |

| Viscosity (at 25°C) | 18 | cPs | — |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

| Specific Gravity (at 25°C) | 0.97 | — | — |

Regulatory & Compliance

- Chemical Inventories

- Clearances

- AMMONYX LO-A is cleared for use user 40 CFR 180.910, pre- and post-harvest applications.

- All components of AMMONYX LO-A are listed in the following countries; the registration numbers for the active ingredients are included in parentheses: United States (TSCA), Europe (EINECS), Japan (ENCS), Canada (DSL), Australia (AICS), Korea (ECL), Philippines (PICCS), New Zealand (NZIoC) and China (EICS).

Safety & Health

- Health Effects

The available toxicity data shows AMMONYX LO-A to be slightly toxic orally to rats, (LD₅₀ >3000 mg/kg). At 2.5% active, AMMONYX LO-A may cause severe eye irritation and minimal irritation to the skin. AMMONYX LOA is expected to cause slight irritation at ≤ 1%.

Packaging & Availability

- Country Availability

- Regional Availability

- Standard Packaging

AMMONYX LO-A is available in bulk and in 55 gallon drums (net weight 425 lb/193 kg).

Storage & Handling

- Storage & Handling

- Normal safety precautions (i.e., gloves and safety goggles) should be employed when handling AMMONYX LO-A. Contact with the eyes and prolonged contact with the skin should be avoided. Wash thoroughly after handling material. It is recommended that AMMONYX LO-A be stored in sealed containers and kept at temperatures not lower than 50°F (10°C) nor higher than 120°F (49°C). Avoid overheating or freezing.

- Bulk Storage Information: Tanks, with a conservation vent, made of 316L stainless steel or fiberglass with an Atlac 382 corrosion liner are recommended. Centrifugal or positive displacement gear pumps and piping should be 316L stainless steel. Recommended storage for bulk tanks is 20-52°C (68-125°F).

- Freeze Statement: If material is frozen, gentle heat [approximately ~95 °F (~35 °C)] and agitation are recommended to ensure the material is homogeneous before use.