Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- CAS No.

- 68439-46-3

- EC No.

- 614-482-0

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Agrochemicals Features

Applications & Uses

- Applications

- Home Care Applications

Properties

- Formulation Type

- Physical Form

- Appearance

- Clear to slightly hazy liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| NPE Equivalent | NP-9 | — | — |

| Cloud Point (1% in water) | 64 | °C | — |

| Ross-Miles Foam Height (in 0.1% actives, initial) | 8 | cm | — |

| Color | 10 | — | Apha Scale |

| Ross-Miles Foam Height (in 0.1% actives, 5min) | 5 | cm | — |

| Critical Micelle Concentration (CMC) | 160 | mg/l | — |

| Actives Content | 95 | % | — |

| pH (1% in Water) | 6.5 | — | — |

| HLB | 13 | — | — |

| Freeze Point | -7 | °C | — |

| Ethylene Oxide Content | 65 | wt% | — |

| Hydroxyl Value | 118 | mg KOH/g | — |

| Viscosity (at 25°C) | 59 | cPs | — |

| Molecular Weight | 484 | g/mol | — |

| Viscosity (at 38°C) | 27 | cPs | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Pour Point | 6 | °C | — |

| Density (at 25°C) | 1 | g/ml | — |

| Density (at 38°C) | 0.988 | g/ml | — |

| Surface Tension (in 0.1% aqueous solution) | 30 | dynes/cm | — |

| Draves Wetting (at 25 °C, 0.1% in Water) | 8 | sec | — |

| Draves Wetting (at 60 °C, 0.1% in Water) | 5 | sec | — |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

The international inventories (country clearances) of BIO-SOFT N-900 can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control Regulations for each country where the end product is intended to be sold or used. If you have any further questions regarding inventories, please contact North America Technical Service at techserv@stepan.com.

Technical Details & Test Data

- General Purpose Cleaning

BIO-SOFT® N-900, BIO-SOFT® N-901, and BIO-SOFT® N-905 quickly tackle everyday dirt.

Method: Gardner abrasion cleaning, ASTM 4488-95 (2001) A5, oily/particulate soil, vinyl tiles, formulation diluted 1:8, 22 °C.

Formulation: 1 wt% nonionc, 1.5 wt% sodium linear alkylbenzene sulfonate (38%), 0.2 wt% sodium citrate.

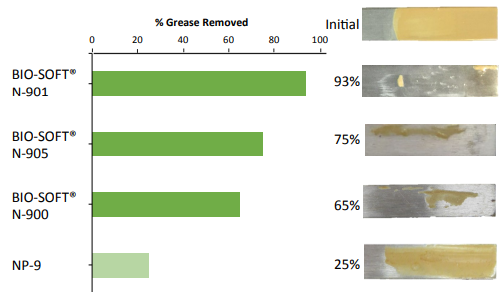

- Heavy Duty Degreasing

BIO-SOFT® N-901 is a superior degreaser that cuts through both industrial and household soils.

Method: Immersion degreasing, lithium grease/used motor oil (50/50 by wt%), stainless steel, 22°C, 1000 RPM, 30 min, gravimetric analysis, required HLB for lithium grease (mixture of lithium stearate and lithium hydroxystearate) = 15 and petroleum oils = 10.

Formulation: 1 wt% nonionic, 1 wt% potassium hydroxide (45%), 1 wt% sodium metasilicate.

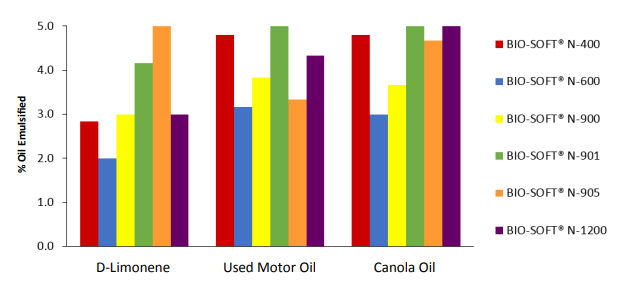

- Emulsification Versatility

BIO-SOFT® N-Series Blends have a high capacity for emulsifying a variety of fragrance, industrial, and food oils.

Method: Oil emulsification capacity, 10 wt% nonionc in deionized water titrated with oil to form a stable emulsion for 20 min, 22°C, required HLB for d-limonene = 12, petroleum oils = 10, canola oils = 7.

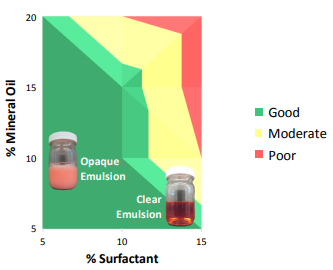

- Emulsification Efficacy

BIO-SOFT® N-400 and BIO-SOFT® N-900 effectively emulsify nonpolar mineral oil.

Method: Nonionic/mineral oil emulsions with red dye, 50/50 wt% of BIO-SOFT® N-400 and BIO-SOFT® N-900 in deionized water, stability qualitatively ranked, 20 min, 22°C, required HLB for mineral oil = 10.5.

Safety & Health

- Toxicity

BIO-SOFT N-900 is slightly toxic orally (LD₅₀ > 2,000 mg/kg), and at 10% active causes slight skin and moderate eye irritation.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace practices should be used to control these exposures.

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage & Handling Information

Bulk Storage Recommendations: BIO-SOFT N-900 should be stored in vessels of 316 stainless steel or fiberglass with a corrosion liner. Heating and agitation are recommended for outside storage. Material should be stored between 95 - 131°F (35 - 55°C). An internal hairpin coil of 316 stainless steel with low pressure steam (under 50 psig) should be used if heating is required. Pumps, pipes and transfer lines should be 316 stainless steel.