Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- INCI Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- CAS No.

- 9003-11-6

- EC No.

- 618-355-0

- Technologies

- Product Families

- Chemical Structure

- Surfactant Type

Nonionic.

Features & Benefits

- Labeling Claims

- Agrochemicals Features

- HII Features

- Industrial Additives Features

- Biodegradability

Publically available data shows this type of chemistry to be inherently biodegradable.

- Benefits

Preservative Free.

- Product Benefits

- Preservative Free

- Product Features

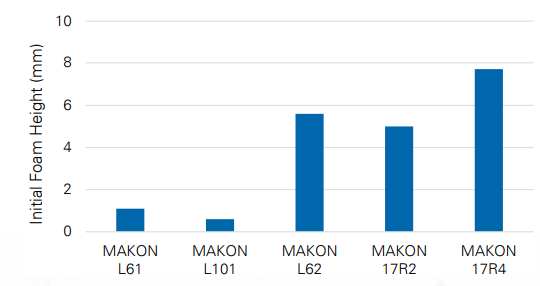

EO-PO-EO block copolymers are best used as individual low-foam surfactants when the EO content is lower, such as MAKON L61 and MAKON L101. Figure 3 shows Stepan’s EO/PO block copolymers that generate less than 1 cm of foam. PO-EO-PO reverse block copolymers, such as MAKON 17R2 and MAKON 17R4, are good foam controllers in the presence of other foaming sources. Reverse block copolymers also create a destabilization of foam structure (Figure 4) and can enhance foam break.

Figure 3: Foamability

Method: Spinning method with Dynamic Foam Analyzer (6,000 rpm, 25 seconds), 0.05 wt% surfactant in deionized water at 25°C.

Applications & Uses

- Applications

- Applicable Processes

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Personal Hygiene Applications

- Skin Care Applications

- Applications

MAKON L101 is a nonionic EO/PO block copolymer that exhibits very good water-in-oil emulsification, low foaming, defoaming, and fast wetting properties. MAKON L101 can be used in a variety of markets including Metalworking, Paints and Coatings, Agriculture, and Industrial. Applications for best fit are anti-foaming, defoaming, oil cutting, dispersants, water-in-oil emulsifiers, emulsion polymerization, and textiles. MAKON L101 is a low ash product.

Properties

- Formulation Type

- Physical Form

- Appearance

- Clear to slightly hazy liquid

- Insoluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH (in 1% in 50:50 IPA:Water) | 5 - 8 | — | — |

| Actives Content | 100 | % | — |

| Water Content | max. 0.2 | % | — |

| Color | max. 50 | — | Apha Scale |

| HLB | 1 | — | — |

| Average Molecular Weight | 3800 | g/mol | — |

| Hydroxyl Value | 29 | mg KOH/g | — |

| Cloud Point (in 10% Aqueous) | 11 | °C | — |

| Cloud Point (in 1% Aqueous) | 15 | °C | — |

| Pour Point | -36 | °C | ASTM D 97 |

| Flash Point | min. 94 | °C | — |

| Viscosity (at 25°C (77 °F) / 38°C (100 °F)) | 638 / 30 | cPs | — |

| Density (at 25°C, 77°F) | 1.02 | g/ml | — |

| Density (at 38°C) | 1.02 | g/ml | — |

| Foam Height (0.1% Aqueous, Initial / 5 min, mm, at 25 °C, 77 °F) | 9 / 9 | mm | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

All components of MAKON L101 are listed in the following countries; the registration numbers for the active ingredients are included in parentheses: Australia (AICS 9003-11-6), Canada (DSL 9003-11-6), China (IECSC 9003-11-6), Japan (ENCS (7)-1246), Korea (ECL Serial No. KE-24574), New Zealand (NZIoC 9003-11-6), Philippines (PICCS 9003-11-6), Taiwan (TCSI 9003-11-6), and United States (TSCA 9003-11-6). It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

Packaging & Availability

- Packaging Type

- Standard Packaging

MAKON L101 is available in drums, totes, and bulk quantities.

Storage & Handling

- Storage & Handling

Normal safety precautions (i.e., gloves and safety goggles) should be employed when handling MAKON L101. Contact with eyes, nose or prolonged contact with skin should be avoided. Wash thoroughly after handling MAKON L101. Product temperatures over 122°F (50°C) are not recommended.

Non-Bulk Storage Recommendations

MAKON L101 should be stored in closed containers and kept in a cool, dry place away from incompatible materials (see Section 10 of the SDS). If material is frozen, it may be fluidized by warming with a drum heater or in a steam room. Drums should be vented prior to heating to avoid excessive pressure build up.

Bulk Storage Recommendations

MAKON L101 should be stored in vessels of 316 stainless steel, but carbon steel is adequate assuming effective moisture exclusion. Elevated storage temperature may be desirable to maintain ease of pumping.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace safety precautions should be used to control these exposures.