Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Fluids & Lubricants Functions

- CAS No.

- 11138-60-6

- EC No.

- 234-392-1

- Technologies

- Product Families

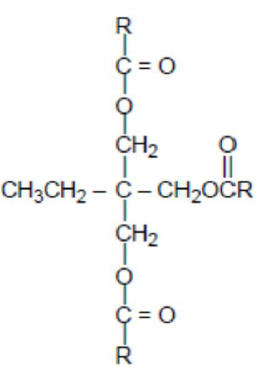

- Chemical Structure

R=C7-9

Features & Benefits

- Fluids & Lubricants Features

- Biodegradability

Product is biodegradable.

- Product Benefits

- Hydrolytically stable, resistant to breakdown in the presence of water

- Excellent lubricity versus industry standard.

- Hard water tolerance capabilities

- Low foaming capabilities

- Oil soluble.

STEPAN® MWA Products Product Class Sub-Class Functional Characteristics Emulsification Lubricity Antifoaming Metal Cleaning Hard Water Tolerance Antimisting Corrosion Inhibition Coupling Agent Biocidal Inert 500 Series Esters Methyl X X Simple X X X Complex X X Hydrolytically Stable X X X

Applications & Uses

- Markets

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Applications

STEPAN MWA-550 is a trimethylolpropane tricaprylate caprate polyol ester that can be used for metalworking formulations in 100% synthetic lubricants for improved lubrication properties, cutting fluids and drawing compounds. STEPAN MWA-550 can enhance the performance of straight oil, semi-synthetic and full synthetic metalworking fluids. STEPAN MWA-550 can offer extreme pressure-type performance without reacting at the work-tool interface. The addition of phosphate esters will enhance performance and replace chlorine.

Properties

- Physical Form

- Appearance

- Water white clear liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Actives Content | 100 | % | — |

| Color | max. 100 | — | Apha Scale |

| Critical Micelle Concentration (CMC) | 2.6 | mg/l | — |

| Density | 0.947 | g/ml | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Moisture Content | 0.1 | % | — |

| Pour Point | -49 | °C | — |

| Refractive Index (at 25°C) | 1.4513 | — | — |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

| Saponification Value | 305 | — | — |

| Viscosity (at 25°C) | 25 | cPs | — |

| Viscosity (at 60 °C) | 10 | cPs | — |

Regulatory & Compliance

- Chemical Inventories

- Clearances

The international inventories (country clearances) of STEPAN MWA-550 can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control regulations for each country where the end-product is intended to be sold or used.

Technical Details & Test Data

- Falex 4-Ball and Falex Pin and Vee Testing

Lubricity is measured using the Falex Four-Ball Wear test and is used to determine the wear-preventing properties of lubricants in metalworking applications. Lubricants are compared using the average size of the scar diameters worn on the three lower clamped balls. STEPAN MWA-550 shows improved lubrication by showing reduced average scar when compared to the current industry standard.

Falex 4-Ball Wear

ASTM D4172BFalex Pin and Vee Test

ASTM D3233Average Scar,

mmTest Load,

lbsFailure

Load, lbsTorque,

lbsTemperature,

⁰FIndustry Standard 0.628 1250 1250 27 166 STEPAN MWA-550 0.476 1750 1729 31 156

Safety & Health

- Health Effects

STEPAN MWA-550 is practically non-toxic orally (LD₅₀ >5 g/kg) and it causes slight skin and minimal eye irritation. See SDS for more information.

Packaging & Availability

- Packaging Type

- Standard Packaging

STEPAN MWA-550 is available in 55-gallon drums.

Storage & Handling

- Storage & Handling

- Normal safety precautions (e.g., gloves and safety goggles) should be employed when handling STEPAN MWA-550. Contact with the eyes and prolonged contact with the skin should be avoided. Wash thoroughly after handling material. See SDS for more information.

- It is recommended that STEPAN MWA-550 be stored in sealed containers and kept in a cool, dry place. Prolonged storage at temperatures above 90°F (32°C) should be avoided. Avoid overheating or freezing.