Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- CAS No.

- 13557-75-0

- EC No.

- 236-942-6

- Technologies

- Product Families

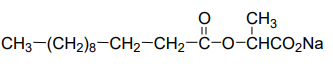

- Chemical Structure

- Surfacant Type

Cationic

Features & Benefits

- Labeling Claims

- Functional Properties

- Foam Booster/Modifier

- Viscosity Builder

- Skin Feel Enhancer

- Emulsifier

- Biodegradability

STEPAN SLL-FB is ultimately biodegradable.

Applications & Uses

- Markets

- Applications

- Bath & Shower Applications

- Hair Care Applications

- Personal Hygiene Applications

- Skin Care Applications

- End Product Uses

Skin Care:

- Body Washes

- Soap Bars

- Liquid Soaps

- Facial Cleansers

- Body Scrubs

Hair Care:

- Shampoos

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 0.81 | g/ml | — |

| Melting Point | 60 | °C | — |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

| Saponification Value | 195 | mg KOH/gm | — |

Regulatory & Compliance

- Chemical Inventories

Safety & Health

- Health Effects

STEPAN SLL-FB is practically non-toxic orally (LD₅₀ = 4 to 12 g/kg) and may be extremely mild to skin and eye depending on concentration.

Packaging & Availability

- Packaging Type

- Standard Packaging

STEPAN SLL-FB is available in drum quantities.

Storage & Handling

- Storage & Handling

- Store under cool, dry conditions. Avoid exposure to temperature above 30°C. Avoid heating in such a manner that “hot spots” could occur resulting in possible discoloration of the product. The container should be kept tightly sealed. Optimum storage temperature is 25°C or lower.

- Avoid direct sunlight for prolonged periods. Approximately 24-48 hours prior to use, container should be placed in a “hot room” at 55-60°C (130-140°F) to facilitate ease of handling. Temperatures exceeding this level can cause darkening of product.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace practices should be used to control these exposures.