Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Product Type

- Cleaning Ingredients Functions

- Technologies

- Product Families

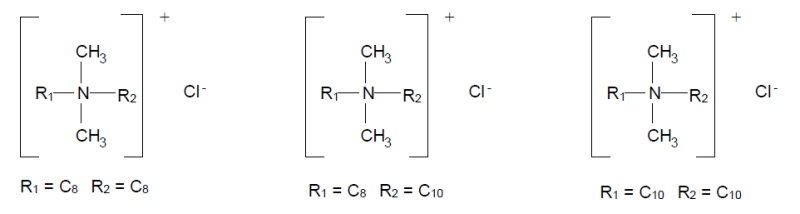

- Chemical Structure

Features & Benefits

- HII Features

- Biodegradability

STEPANQUAT products are biodegradable.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Applications

STEPANQUAT 818 and STEPANQUAT 8188 may provide cationic surfactant, dispersant or emulsifier properties in formulations. STEPANQUAT 818 and STEPANQUAT 8188 may be considered for use as:

- Emulsion breakers (to de-stabilize emulsions stabilized by anionics)

- Used to make hydrophobized clays, and may hydrophobize other surfaces with negative charges (e.g. sand)

- Specialty emulsifiers

- Solids wetter and wax dispersants

Properties

- Physical Form

- Appearance

- Clear liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Color | max. 300 | — | Apha Scale |

| Density | 0.89 | g/ml | — |

| Flash Point | 44 | °C | PMCC Flash Point Tester |

| Free Amine and Amine Hydrochloride | max. 2.4 | % | — |

| pH (in 10% aqueous) | 7.5 | — | — |

| Pour Point | 4 | °C | — |

| Regulated Volatile Organic Chemicals (Ethanol) | 9 | % | U.S. EPA |

| Viscosity (at 25°C) | 210 | cPs | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

- All components of STEPANQUAT 818 quaternaries are listed in the following countries; United States (TSCA), Australia (AICS), Canada (DSL), China (IECSC), Japan (ENCS), Korea (ECL), New Zealand (NZIoC), Philippines (PICCS), and Taiwan (TCSI).

- It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

Safety & Health

- Health Effects

STEPANQUAT 818 products are moderately toxic orally (LD₅₀ = 50-500 mg/kg) and corrosive to skin and eyes at 50% active.

Packaging & Availability

- Standard Packaging

STEPANQUAT 818 products are available in bulk quantities and in 55 gal drums (193 kg for STEPANQUAT 818; 181 kg for STEPANQUAT 8188).

Storage & Handling

- Storage & Handling

- Handle liquid STEPANQUAT products with care; use away from sparks and open flame. Use in well ventilated area. Avoid contact with eyes, nose or prolonged skin contact. Gloves, protective clothing, safety goggles and face shield should be worn when handling STEPANQUAT products. Wash thoroughly after handling a product.

- It is recommended that STEPANQUAT products be stored in sealed containers and kept in a cool, dry place. If product is frozen, it should be heated gently and stirred to ensure it is homogeneous before use.

- Bulk Storage Information: STEPANQUAT quaternaries can be stored in vessels of 316 stainless steel or fiberglass with a corrosion liner. Contact between quaternaries and anionic materials must be avoided. At use dilution, STEPANQUAT quaternaries are non-corrosive to most plastics, natural rubber, stainless steel, monel metal, iron, brass, aluminum, lead and tin; however, STEPANQUAT quaternaries as supplied, may be corrosive to the materials listed above.

- Liquid STEPANQUAT products should be stored between 29 – 49 °C (85 – 120 °F). An internal hairpin coil of 316 stainless steel with low pressure steam (under 50 psig) should be used if heating is required. Mild agitation is recommended while storing to maintain homogeneity. Pumps, pipes and transfer lines should be 316 stainless steel. Rubber hoses with Teflon cross-linked polyethylene with 316 stainless steel fittings are recommended for loading and unloading.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and/or mists. Engineering controls, personal protective equipment, and other workplace practices should be used to control these exposures.