Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- CAS No.

- 78330-24-2

- EC No.

- 616-610-0

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Multifunctional, APE-Free Wetting Agent for Waterborne Coatings

STEPCOTE™ W-846 is an alternative to alkyl phenol ethoxylates (APE) for use in waterborne coatings. This well-rounded, APE-free additive can provide benefits to gloss development, hiding, pigment dispersion and temperature stability while preserving the wet scrub resistance of the coating.

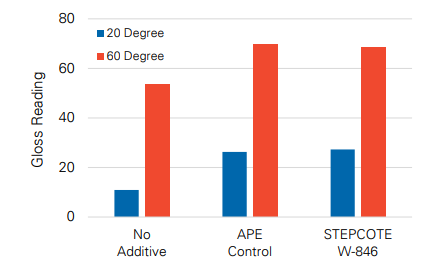

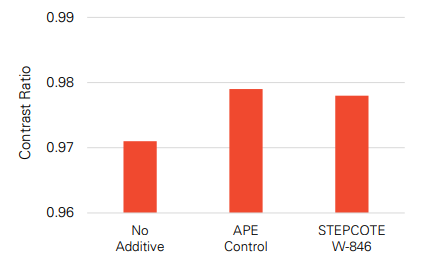

Enhanced Gloss and Hiding

Improved gloss and hiding are indicative of optimized pigment dispersion. In Figure 1, STEPCOTE™ W-846 showed improved 20° and 60° gloss readings compared to a coating without an additive and comparable performance to a commercial APE control (nonyl phenol 6-mole ethoxylate phosphate ester). When compared to a coating without additive, STEPCOTE W-846 improved titanium dioxide (TiO2 ) dispersion that resulted in enhanced hiding (Figure 2).

Figure 1. Gloss Development

ASTM D523: additive dosed at 3 lbs/100 gallons (active), all acrylic, 29.8% PVC, <50 g/L VOC.

Figure 2. Hiding

ASTM D2805: additive dosed at 3 lbs/100 gallons (active), all acrylic, 29.8% PVC, <50 g/L VOC.

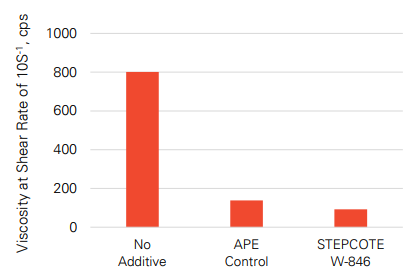

The relative quality of the dispersion can be evaluated by change in viscosity. Lower viscosity indicates efficient pigment wetting and better dispersion quality. When compared to a coating without additive and a commercial APE control, STEPCOTE W-846 exhibited improved dispersion quality of a 70% TiO2 pigment concentrate at a dose of 0.5% (Figure 3).

Figure 3. TiO2 Dispersion Quality

Additive tested at 0.5% use level with 70% TiO2 due to optimal viscosity. Viscosity measured at Shear Rate of 10 S-1.

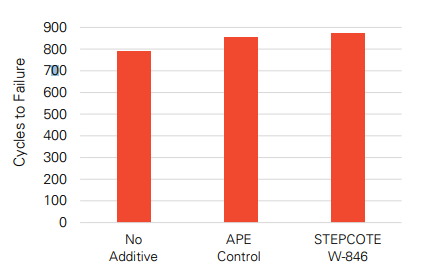

Maintained Durability

The wet scrub resistance of a coating was maintained after the addition of STEPCOTE™ W-846. In Figure 4, STEPCOTE™ W-846 exhibits equivalent performance compared to a coating without additive and a commercial APE control.

ASTM D2486: additive dosed at 3 lbs/100 gallons (active), all acrylic, 29.8% PVC, <50 g/L VOC.

Improved Temperature Stability

STEPCOTE™ W-846 can provide improved temperature stability to a coating. After three freeze/thaw cycles, the coating with STEPCOTE™ W-846 maintained its viscosity in contrast to the commercial APE control (Table 1). After high temperature evaluations, STEPCOTE™ W-846 demonstrated the least amount of viscosity loss and separation when compared to a coating without additive and a commercial APE control (Table 2).

Table 1. Freeze/Thaw Stability.

Additive Freeze/Thaw Cycles Passed KU Viscosity Change After 3 Cycles No Additive 0 N/A APE Control 3 -9 STEPCOTE W-846 3 -1 ASTM D2243: additive dosed at 3 lbs/100 gallons (active), all acrylic, 29.8% PVC, <50 g/L VOC.

Table 2. High Temperature Stability: 120° F

Additive KU Viscosity Change After 2 Weeks Syneresis Settling No Additive -9 Moderate Moderate APE Control -6 Slight Slight STEPCOTE W-846 -4 None Slight ASTM D1849: additive dosed at 3 lbs/100 gallons (active), all acrylic, 29.8% PVC, <50 g/L VOC

Applications & Uses

- Markets

- Coating Type

- Applications

STEPCOTE™ W-846 is an effective wetting agent for use in waterborne coatings. It can be incorporated during the letdown phase of production or post added to the final formulation. Typical use level, based on active content, is 2 – 6 lbs/100 gallons, however, optimal dosing should be determined by performing a ladder study. STEPCOTE™ W-846, although primarily a wetting agent, may positively impact the following coatings properties:

- Gloss

- Low Foaming

- Temperature Stability

- Color Acceptance

- Hiding

Properties

- Physical Form

- Appearance

- Clear light yellow, viscous liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Actives Content | 45 | % | — |

| Density (at 25°C) | 1.07 | g/ml | — |

| pH | max. 2 | — | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

The international inventories (country clearances) of STEPCOTE™ W-846 can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

Packaging & Availability

- Packaging Type

- Standard Packaging

STEPCOTE™ W-846 is available in bulk quantities.

Storage & Handling

- Storage & Handling

- Bulk Storage Information: Elevated storage temperature may be desirable to maintain ease of pumping, but product should be stored long term at ambient temperature.

- Non-Bulk Storage Information: STEPCOTE™ W-846 which has been stored in drums at temperatures below 50 °F (10 °C) may thicken or solidify. The surfactant may be fluidized by warming with a drum heater or in a steam room. Drums should be vented prior to heating to avoid excessive pressure build up. Product temperatures over 130 °F (54 °C) are not recommended.

- Normal safety precautions (i.e., gloves and safety goggles) should be employed when handling STEPCOTE™ W-846. Contact with eyes, nose and prolonged contact with skin should be avoided. Wash thoroughly after handling material.