Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Enzyme Type

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Invertase

- Food Additive Number

- E 1103, INS 1103

- Technologies

Features & Benefits

- Food Ingredients Features

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

Properties

- Appearance

- Granulated powder

- Chemical Properties

- Typical Properties

- Microbiological Values

- Nutritional Information

- Nutritional Data

Description Value Unit/100g Energy 1.556 kJ Energy 366 kcal Fat 0.01 g of which: saturated fatty acids (FA) 0 g Carbohydrates 89 g of which: Sugar 82 g Fiber 0 g Proteinn (N x 6,25) 2.5 g Salt (Sodium x 2.5) 0.0125 g Sodium 0.005 g

| Value | Units | Test Method / Conditions | |

| Arsenic Content | max. 3 | mg/kg | AAS |

| Cadmium Content | max. 0.5 | mg/kg | AAS |

| Lead Content | max. 5 | mg/kg | AAS |

| Loss on Drying | max. 14 | g/100g | drying oven; 3h 105°C |

| Mercury Content | max. 0.5 | mg/kg | AAS |

| Value | Units | Test Method / Conditions | |

| Invertase | 19000 - 21000 | g/cm³ | according to Sumner |

| Value | Units | Test Method / Conditions | |

| Escherichia coli | Negative | cfu/25g | M. Colif.-Agar 36°C/48h |

| Salmonella | Negative | cfu/25g | DIN EN ISO 6579 |

| Total Plate Count | max. 50000 | cfu/g | DIN EN ISO 4833 |

| Value | Units | Test Method / Conditions | |

| Energy | 1.556 | kJ/100 g | — |

| Fat Content | 0.01 | g/100g | — |

| Saturated Fatty Acids | 0 | g/100g | — |

| Carbohydrates | 89 | g/100g | — |

| Sugar | 82 | g/100g | — |

| Fibre | 0 | g/100g | — |

| Protein (N x 6.25) | 2.5 | g/100g | — |

| Salt (Sodium x 2.5) | 0.0125 | g/100g | — |

| Sodium Content | 0.005 | g/100g | — |

Regulatory & Compliance

- Regulatory Information

Allergen Information: contains the allergen milk and lactose according to Regulation 1169/2011/EG, Annex II

Health Information: The products are suitable for human consumption if used accordingly to recommendations and officially allowed to be sold within Germany and the EU. The product is food grade and conforms with the current european food law.

GMO: This product is not a genetically modified organism (GMO), nor does it contain any GMO or any recombinant DNA.

All the non-enzymatic constituents of the product (e.g. carriers, stabilizing agents, free-flowing agents etc.) originate from non-genetically modified sources. Due to the ubiquitous presence of GMO organisms, absence of minor traces of GMO material cannot be guaranteed, but in any case, the content of unintentionally present GMO material will be below 0.9%, in accordance to EU guidelines 1830/2003 and 1829/2003. The product is used as processing aid in food manufacturing processes, and therefore labeling is not required in the EU. National regulations must be observed.Product suitability:

Yes No Vegetarian X Vegan X BSE/TSE Information: The mentioned product does not represent a BSE (Bovine Spongiform Encephalopathy) and/or TSE (Transmissible Spongiform Encephalopathy) risk.

Irradiation: Neither the product nor its ingredients have been treated with ionizing radiation according to Directive 1999/2/EC and 1999/3/EC

Nanoparticles: The product does not contain ingredients in the form of engineered nanomaterials as defined in Regulation (EU) 2015/2283.

Contamination/Residues: The product complies with: Regulation (EC) No 396/2005 and its amendments regarding maximum levels for pesticide residues in foodstuffs. Regulation (EC) No 1881/2006 and its amendments regarding especially maximum levels for heavy metals, mycotoxins, dioxins and PCB in foodstuffs.

Conformity of the Packaging: The packaging material complies with the provisions of Regulation (EC) No 1935/2004 and Regulation (EU) No 10/2011.

Technical Details & Test Data

- Production of Pryaniki

- Improved softness

- Prolonged shelf life

- Increased color formation

Russian Pryaniki very often become hard and dry after just a short time, because many manufacturers produce them with a mixture of sucrose and water as a sweetener. However, the sugar recrystallises quickly, causing the product to harden.

These sensory changes during storage can be prevented when using invert sugar syrup produced with Sweetase 20 P. This way, the recrystallisation of sucrose is reduced and thus the soft bite of delicious Pryaniki can be maintained. A prolonged shelf life is the result.

Production of Pryaniki

1. Add enzymatically inverted sugar syrup (see production procedure below) to the flour in a double-Z kneader and mix for 10 minutes.

2. Add the shortening and mix for 5 more minutes.

3. Dissolve the ammonium bicarbonate in water, add the solution and the sodium bicarbonate to the dough, and finish mixing.

4. Mold/shape the pieces and bake at 210 °C for 12 minutes.

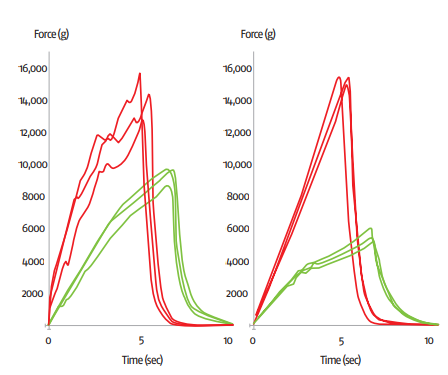

Raw material Recipe with invert sugar syrup Original recipe with sucrose Wheat flour, 0.55 % ash 995 kg 995 kg Invert sugar syrup produced with Sweetase 20 P 886 kg Sucrose, crystalline 585 kg Water 10 kg 311 kg Shortening 55 kg 55 kg Ammonium bicarbonate 8 kg 8 kg Fig. 1: Softness of Pryaniki measured with a texture analyser after three days (left) and 17 weeks (right). Red line shows original Pryaniki produced with sucrose and green line shows Pryaniki with Sweetase inverted syrup

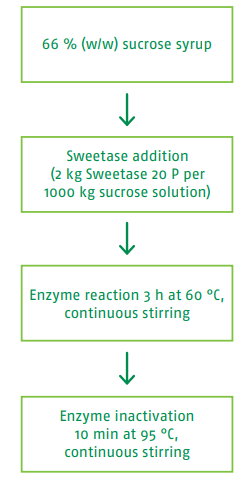

Production of Sweetase invert sugar syrup

1. A 66 % (w/w) sucrose solution is the starting material for sucrose inversion (e.g. 660 kg filled up to 1000 kg).

2. 2 kg of Sweetase 20 P are added to this sugar syrup.

3. The syrup is heated to 60 °C during continuous stirring.

4. Afterwards, the enzyme is inactivated by increasing the temperature to 95 °C for 10 minutes.

Packaging & Availability

- Packaging

Cardboardbox with PE-Inliner, 25 kg net

Storage & Handling

- Storage & Shelf Life

Min. 18 months if stored cool and dry in closed original packing