Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Composites End Use

- Composites Processing Methods

- Use

This continuous filament mat is designed primarily for reinforcing pultruded shapes. This mat is characterized as having fast wet-through, good wet-out, good conformability, good surface smoothness and excellent mat strength. This mat is normally used for pultrusion unless special requirements dictate using the following modification.

Properties

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

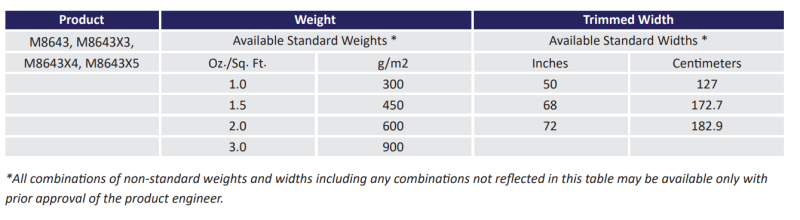

- Available Products

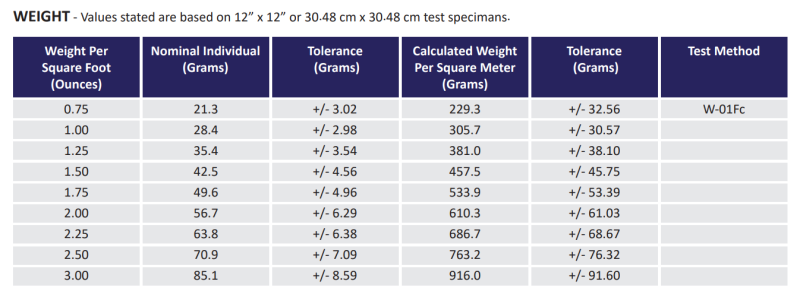

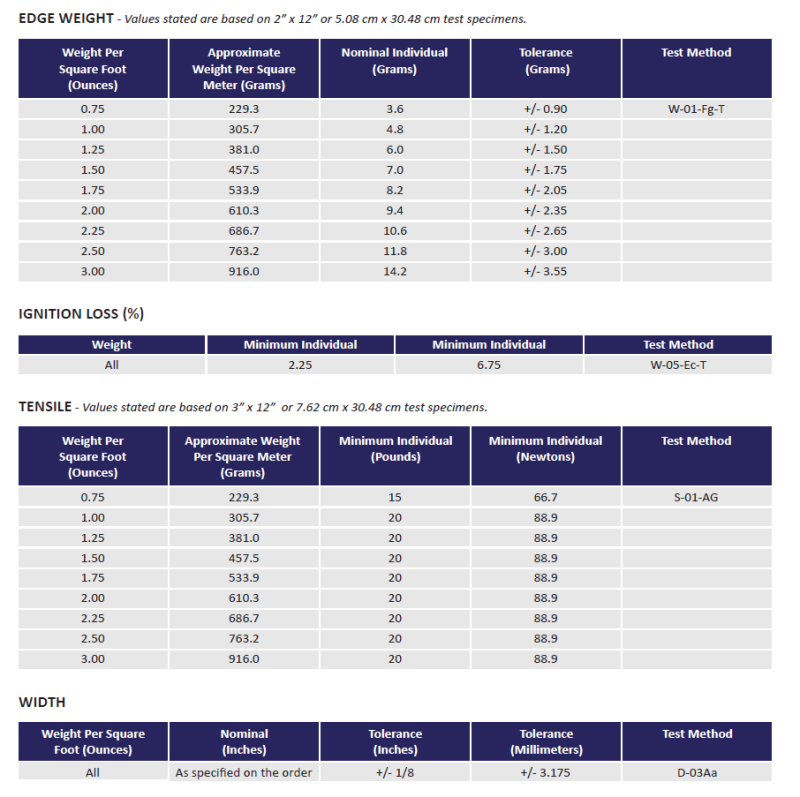

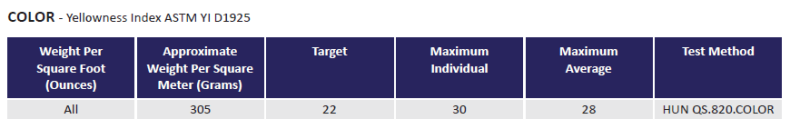

- Product Acceptance Limits & Test Methods

- Minimum Recommended Laminate Thickness

- Preparation for Shipment

ROLL-UP & TELESCOPING REQUIREMENTS

The mat is wound on a 4" (10.2 cm) inside diameter paper tube, having a single tube

with a length the same as the mat width with the following tolerances:- For rolls 68” (172.7 cm) and greater, the tube length tolerances are plus 0",minus 1/2" (-1.27 cm)

- For rolls less than 68” (172.7 cm), the tube length tolerances are plus 0”,minus 1” (-2.54 cm)

*The mat will be so wound that the maximum length of mat telescoping will not exceed 1/2” (1.27 cm). Telescoping is described as the condion where successive wraps of mat

are not perfectly aligned one upon the other, bringing about a concave effect on one end of the roll and a convex effect on the other.

No tube will protrude past the product.ROLL DIAMETER

All full rolls are manufactured to a diameter range of 19" (48.26 cm) to 22" (55.88 cm). Domestic Note: A maximum of one (1) roll per pallet may be under 19" (48.26 cm), but not less than 9" (22.86 cm). Export Note: A maximum of one (1) roll per pallet may be under 19" (48.26 cm), but not less than 14" (35.56 cm).

CONTINUOUS LENGTH ROLLS

All rolls will be continuous, one-piece lengths with no wrap-ins permitied.

Packaging & Availability

- Packaging Type

- Standard Packing Method

Product Identification

Cores will be printed on the inside to idenfy type, ounces, and tracking.

A content label will adequately identify each roll.

WRAPPING

The rolls are wrapped in polyethylene.

PACKAGING

The rolls are multiple packed, twelve (individual or common) rolls for widths less than or equal to 42” (106.68 cm) or six (individual or common) rolls for other widths up to 84”

(213.36 cm), on a 66” (167.64 cm) x 44” (111.76 cm) varying height pallet. Greater than 84” (213.36 cm) are on a 116” (294.6 cm) x 44” (111.76 cm) varying height pallet. Also,

may be heat treated or block.

PALLETIZATION

The rolls of mat will be palletized with pallet stretch packaging.