Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 21645-51-2

- EC No.

- 244-492-7

- Technologies

Features & Benefits

- Product Highlights

Maxfil is a series of engineered alumina trihydrate (ATH) flame retardant fillers created for maximum filler loadings, extremely low viscosities, increased flame retardance and decreased formulation costs. Using Maxfil MX100can achieve better glass wet-out, help reduce shrinkage and warpage, while also increasing the ability to achieve UL 94-VO, UL94 5VA and ASTM E84 Class 1 flame & smoke ratings.

Applications & Uses

- Markets

- Applications

- What is Alumina Trihydrate?

Alumina Trihydrate (A1203•3H20) is the most widely used flame retardant in the world due to its versatility and low cost. Available in different particle sizes, it can be used in a wide range of polymers at processing temperatures below 220°C. ATH is non-toxic, halogen-free, chemically inert, and has low abrasiveness. Additional benefits are arc and track in plastics to arcing, acid resistance, and smoke suppression. At about 2200C, ATH begins to decompose endothermically releasing approximately 35% of its weight as water vapor.

A1203.3H20 + HEAT------> A1203 + 3 H20Alumina Trihydrate acts as heat sink thereby retarding pyrolysis and reducing the burning rate. "Ihe water vapor released has an added effect of diluting combustion gasses and toxic fumes.

Properties

- Flame Rating

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Median Particle Size | 4.5 | μm | — |

| Mesh (+325) | 0.5 | % | — |

| Packed Bulk Density | 46 | lb/ft3 | — |

| Loose Bulk Density | 40 | lb/ft3 | — |

| Oil Absorption | 3.5 | ml/100g | — |

| Mesh (+100) | 0 | % | — |

| Mesh (+200) | 0 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Test Data

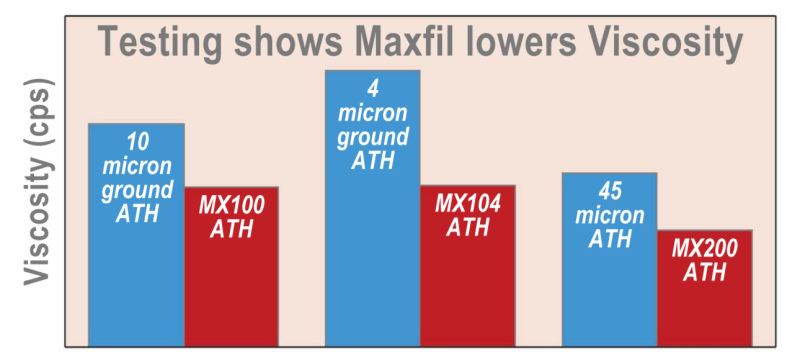

Testing shows MX104 results in a 42% decrease in viscosity over a 4 micron ground ATH.

A 4.5 micron engineered ATH, MX104, allows for higher filler loadings and lower resin requirements than can be achieved with typical ATH grades. MX104 will lower production cost and increase flame retardance & smoke suppression.