Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Product Applications

- For the most practical applications, 1.0 part of Thanecure ZM provides a good balance between cure rate and processing safety.

- As the concentration of Thanecure ZM increases above 1.0 part, cure rate improves only slightly with reduced processing safety. If it becomes necessary to increase scorch time for greater processing safety, MBT evel can be reduced to 1.0 phr without changing the amount of Thanecure ZM.

- Zinc oxide is not compatible with some polyester polyurethane rubber.

- Thanecure ZM, which contains active zinc, needs to be incorporated to insure proper state of cure.

- Thanecure ZM is used to cure both polyester (e.g., Millathane 76, Millathane HT) and polyether (e.g., Millathane E34, Millathane E40, Millathane CM) and other types of sulfur curable polyurethane rubber.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

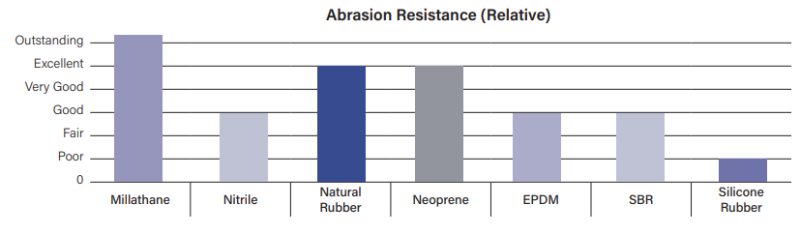

- Abrasion Resistance

- Abrasion resistance is the ability of a surface to resist wearing due to contact with another surface moving with respect to it.

- High resistance to abrasion is important in applications like rollers, belting, and helicopter dust covers.

- The DIN Abrasion Test (ASTM D5963) is one of the most common tests for measuring abrasion resistance.

- It's where a rotating cylindrical sample is passed across a rotating drum of abrasive and the amount of sample volume lost is measured.

- Typical abrasion resistance values for Millathane millable urethane compounds is 50-80 mm³.

- Some compounds can have abrasion resistance values as low as 25 mm³, depending on the polymer, cure system, and formulation.

- Polyurethane rubber provides the highest abrasion resistance of any rubber, synthetic or natural.

- Laboratory tests do not always predict the advantage of Millathane compounds over other rubbers, but field experience often shows a tremendous improvement in product lifetime when millable urethane replaces conventional rubber.