Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Characteristics

BondSeal BS8350 is a high bonding strength adhesive. It is a non-slump (thixotropic), additioncuring, one component silicone that cures at elevated temperature to a very tough rubber with excellent bonding strength to various plastics and substrates. It is non-corrosive and self-priming adhesion, and can be automated to dispense from needle or hand extruded from cartridge.

- Special Features & Benefits

- One part for easy applying

- Very strong bonding to various substrates

- Non-slump, non-sag (thixotropic)

- Low bleeding, low volatile

- Low thermal stress

Applications & Uses

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Cure Method

- Typical Applications

- Seal lids, covers, housings, connectors

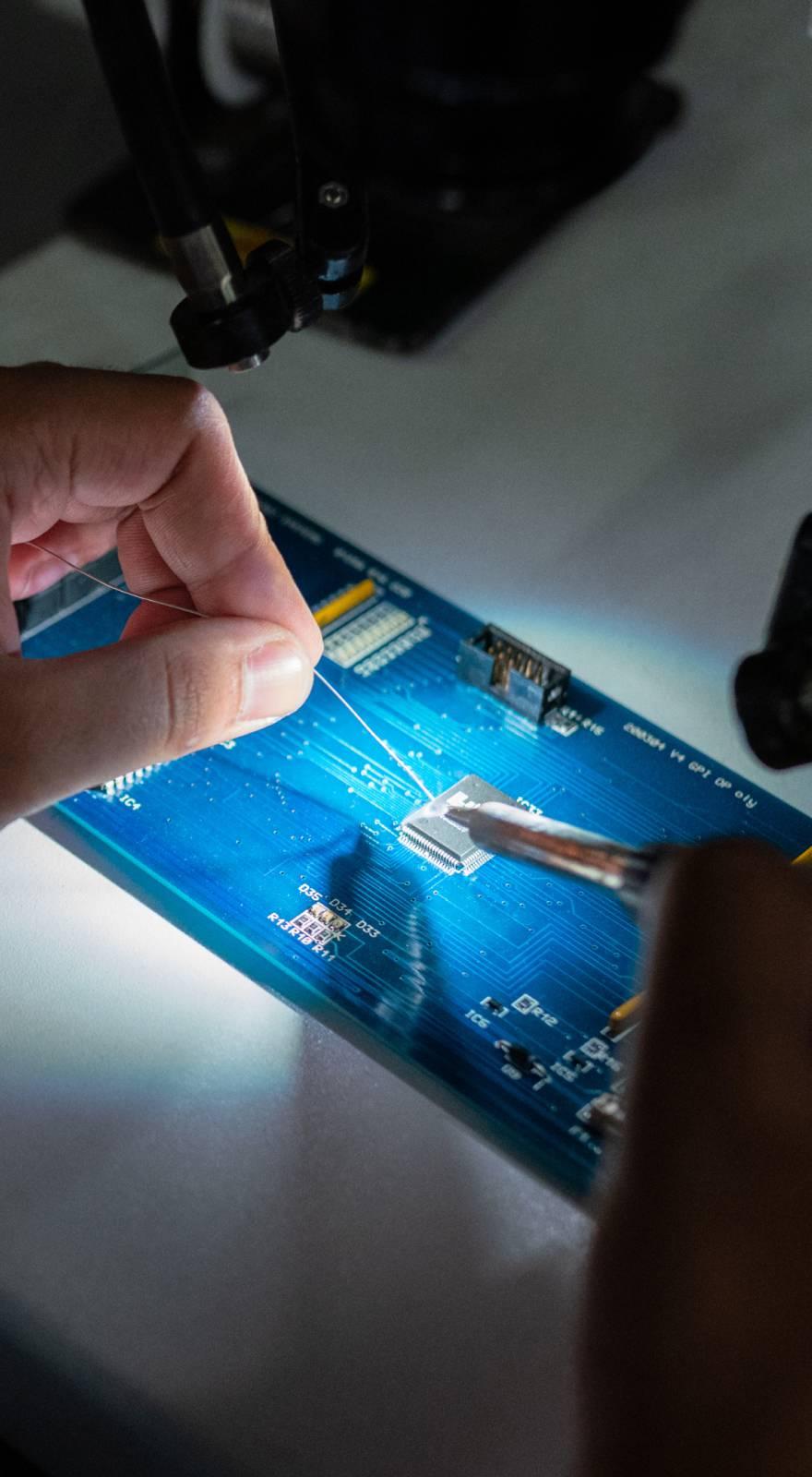

- Attach PCBs, base plates, components

- Encapsulate parts, cavities

- Automotive electronics

- Semiconductor and Telecommunications

- Vibration dampening

- Thermal stress coupling

- For flowable version of this adhesive, please select the United Adhesives’ product BondSeal BS8360.

- For thermally conductive bonding adhesives, please select the United Adhesives’ products ThermoBond 3519 or ThermoBond 3821.

- Processing Instruction

- Important! BondSeal BS8350 is platinum cure system. Please keep applied surface clean and avoid using this material on any surface that contains sulfur, amine, phosphorous, organo-metals, acid, etc. because these contaminants could inhibit the cure the material.

- We recommend running preliminary tests to optimize conditions for the particular application. Comprehensive processing instructions can be obtained by contacting directly to United Adhesives Inc.

Properties

- Color

- Typical Properties

- Typical Cured Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.3 | Gram /cc | ASTM D792 |

| Viscosity (25°C) | 45.0 | Pa.s | ASTM D2196 |

| Value | Units | Test Method / Conditions | |

| Adhesion (Al/Ai Lap Shear, 250°C) | 550.0 | psi | ASTM D3163 |

| Cure Time (125°C) | 60.0 | Min | DSC |

| Cure Time (150°C) | 30.0 | Min | DSC |

| Dielectric Constant (100 Hz) | 3.0 | — | ASTM D150 |

| Dielectric Strength | min. 480 | Volt/mil AC | ASTM D149 |

| Dissipation Factor (100 Hz) | max. 0.01 | — | ASTM D150 |

| Elongation | 250.0 | % | ASTM D638 |

| Hardness | 62.0 | Shore A | ASTM D2240 |

| Tensile Strength | 5.8 | Mpa | ASTM D638 |

| Glass Transmission | -120.0 | °C | TGA |

| Thermal Conductivity | 0.3 | W/m-K | ASTM D5470 |

| Useful Temperature Range | -55 to 200 | °C | TGA |

| Volume Resistivity | min. 10E+14 | Ohm-cm | ASTM D257 |

Safety & Health

- Safety

BondSeal BS8350 silicone contains neither toxic nor corrosive substances that might require special handling precautions. General hygiene regulations should be observed.

Packaging & Availability

- Packaging Type

Storage & Handling

- Shelf Life

- Minimum 3 months at 4°C (Viscosity double)

- Storage

BondSeal BS8350 has a shelf life of at least 3 months when stored at ~4°C in the originally sealed container. Storage beyond the date specified does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.