Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Characteristics

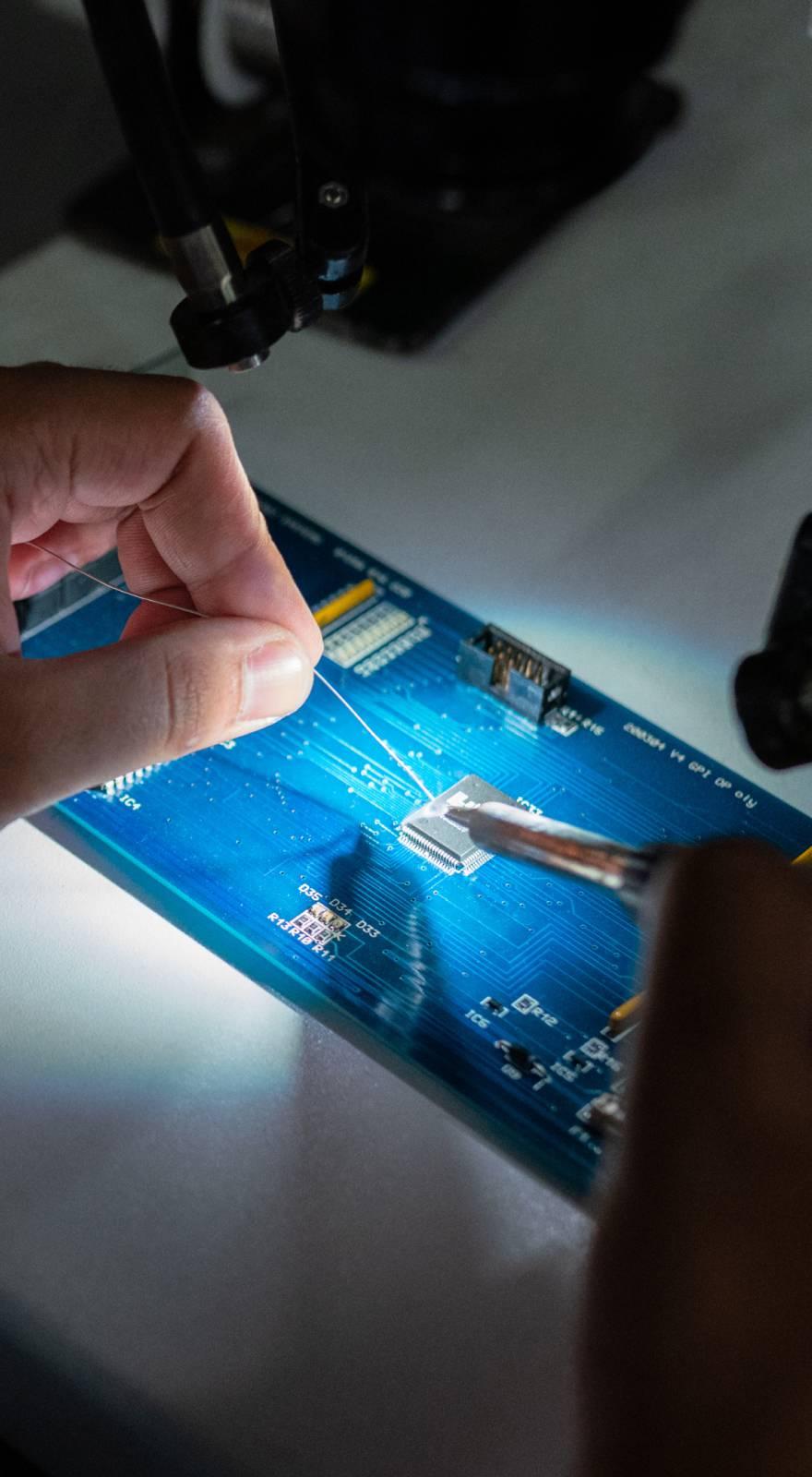

SilCoat SC8026 is a two-part, thixotropic (nonsag) coating and globe-top potting gel. It is a dispensable, addition-curing, silicone that cures at elevated temperature to a very firm rubbery gel with excellent adhesion to various plastics and metals. It is non-corrosive and self-priming adhesion, and can be automated to dispense from pails or hand extruded from cartridge.

- Special Features & Benefits

- Soft and flexible for stress compliance

- Excellent dielectric properties

- Mechanical shock and vibration damping

- Low bleeding, low volatile

- Broad range of temperature stability

Applications & Uses

- Applications

- Typical Applications

- Globe-top coating or potting

- Seal lids, covers, housings, connectors

- Coat or pot parts and cavities

- Automotive electronics

- Semiconductor and Telecommunications

- Vibration dampening

- Thermal stress coupling

For the flowable version of this coating gel, please select the United Adhesives’ product SilCoat SC8022.

- Processing Instruction

- Important! SilCoat SC8026 is platinum cure system. Please keep applied surface / housing clean and avoid using this material on any place that contains sulfur, amine, phosphorous, organo-metals, acid, etc. because these contaminants could inhibit the cure the material.

- We recommend running preliminary tests to optimize conditions for the particular application. Comprehensive processing instructions can be obtained by contacting directly to United Adhesives Inc.

Properties

- Color

- Physical Form

- Typical Properties

- Typical Cured Properties

| Value | Units | Test Method / Conditions | |

| Density (As Mixed) | 0.98 | Gram /cc | ASTM D792 |

| Mixing Ratio | 1:1 | Vol./ Wt. | - |

| Viscosity (25°C, Mixed) | 25000.0 | cP.s | ASTM D2196 |

| Value | Units | Test Method / Conditions | |

| Coefficient Of Thermal Expansion | 260.0 | ppm/°C | IPC-TM-650 |

| Cure Time (125°C) | 15.0 | Minutes | DSC |

| Cure Time (25°C) | approx. 12 | Hours | DSC |

| Dielectric Constant (100 Hz) | 2.6 | - | ASTM D150 |

| Dielectric Constant (100 Hz) | 2.66 | - | ASTM D150 |

| Dielectric Strength | min. 450 | Volt/mil AC | ASTM D149 |

| Dissipation Factor (100 Hz) | max. 0.003 | - | ASTM D150 |

| Dissipation Factor (100 Hz) | max. 0.001 | - | ASTM D150 |

| Hardness | 40.0 | Shore A | ASTM D2240 |

| Pot / Work Life (25°C) | 60.0 | Minutes | Viscosity double |

| Glass Transmission | -120.0 | °C | TGA |

| Useful Temperature Range | -55 to 200 | °C | TGA |

| Volume Resistivity | min. 10E+14 | Ohm-cm | ASTM D257 |

| Weight Loss In Cure | max. 0.5% | Weight % | TGA |

Safety & Health

- Safety

SilCoat SC8026 silicone contains neither toxic nor corrosive substances that might require special handling precautions. General hygiene regulations should be observed.

Packaging & Availability

- Packaging Type

Storage & Handling

- Shelf Life

- Minimum 6 months (Viscosity double)

- Storage

SilCoat SC8026 has a shelf life of at least 6 months when stored at < 24°C in the originally sealed container. Storage beyond the date specified does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.