Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Characteristics

ThermoBond 3830 is a very high thermally conductive adhesive using Boron Nitride as filler to provide superior thermal conductivity. It is a non-slump, addition-curing, ready-to-use, twocomponent silicone that cures at elevated temperature to a rubber with excellent bonding strength. The cured material provides stress compliance for thermal cycles. ThermoBond 3830 is both dispensable and printable.

- Special Features & Benefits

- High thermal conductivity

- Almost constant properties from –50 to 180 °C

- Low modulus for stress compliance

- Low bleeding, low volatile

- Strong adhesion to many substrates without using primer

Applications & Uses

- Applications

- Cure Method

- Typical Applications

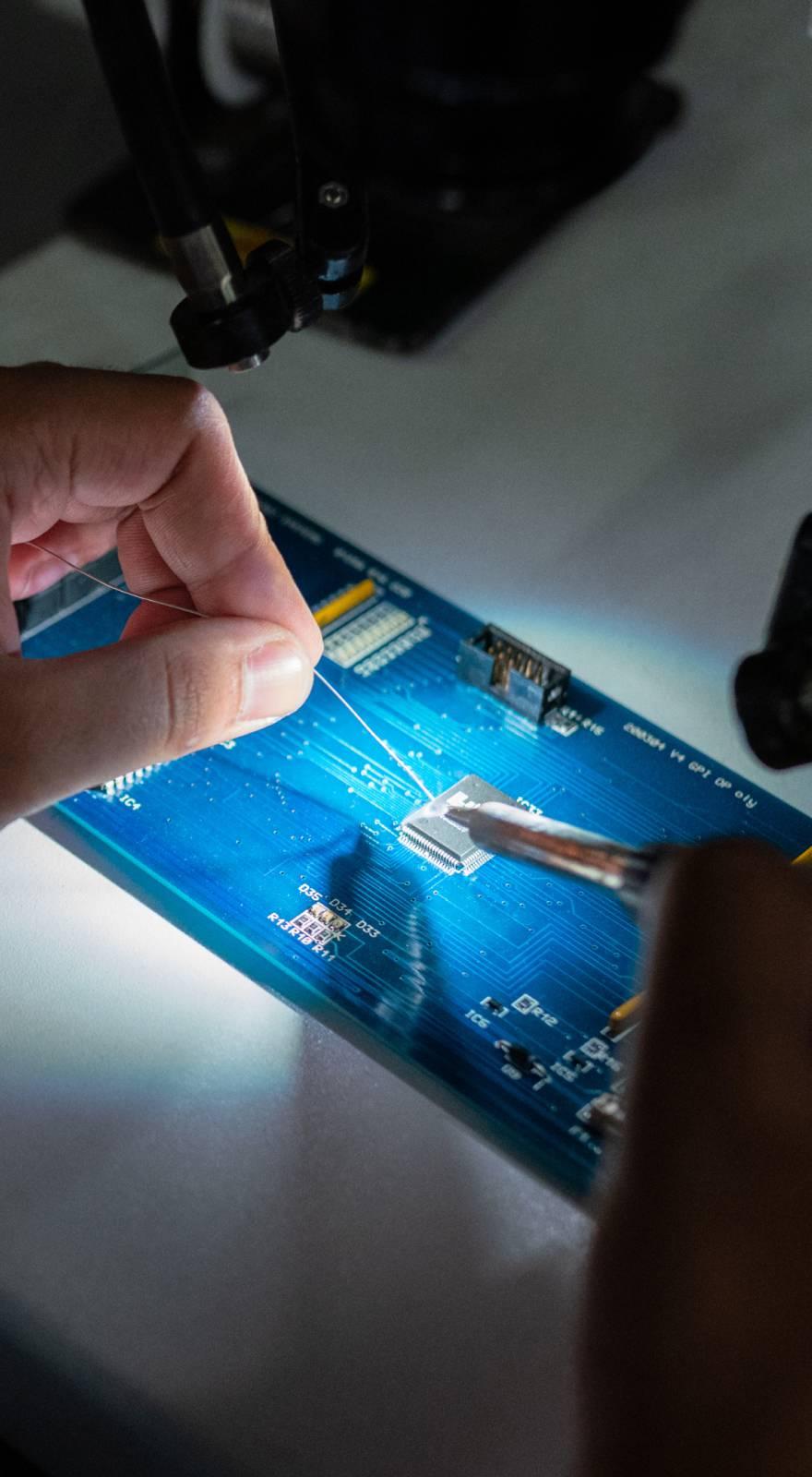

- Bonding of electronic parts to dissipate heat

- Automotive electronics

- Semiconductor and Telecommunications

- Between high heat power device and heat sink

- Thermally conductive vibration dampening

- Couple thermal stress while dissipating heat

- Processing Instruction

- Important! ThermoBond 3830 is platinum cure system. Please keep applied surface clean and avoid using this material on any surface that contains sulfur, amine, phosphorous, organo-metals, acid, etc. because these containments could inhibit the cure of the material.

- For the package in a container (not in a cartridge), to ensure homogeneity of the material, it is suggested that the component be stirred thoroughly before it is removed or processed in order to uniformly disperse any fillers that might have settled during storage.

- We recommend running preliminary tests to optimize conditions for the particular application. Comprehensive processing instructions can be obtained by contacting directly to United Adhesives Inc.

Properties

- Color

- Typical Properties

- Typical Cured Properties

| Value | Units | Test Method / Conditions | |

| Density (As Mixed) | 1.4 | Gram /cc | ASTM D792 |

| Mixing Ratio | 1:1 | By volumne or weight | ITM |

| Viscosity (As Mixed At 25°) | 230000.0 | cps | ASTM D2196 |

| Value | Units | Test Method / Conditions | |

| Adhesion (Alvai Lap Shear, 25°C) | 580.0 | psi | ASTM D3163 |

| CTE | 120.0 | Ppm/C | IPC-TM-650 |

| Cure Time (125°C) | 15.0 | Min | DSC |

| Dielectric Constant (100 Hz) | 3.0 | - | ASTM D150 |

| Dielectric Strength | 500.0 | Volt/mil AC | ASTM D149 |

| Dissipation Factor (100 Hz) | max. 0.01 | - | ASTM D150 |

| Hardness | 63.0 | Shore A | ASTM D2240 |

| Pot Life (25°C) | 24.0 | Hr | Viscosity double |

| Glass Transmission | -120.0 | °C | TGA |

| Thermal Conductivity | 3.2 | W/m-K | ASTM D5470 |

| Volume Resistivity | 250000000000000.0 | Ohm-cm | ASTM D257 |

| Weight Loss In Cure | 0.005 | Weight % | TGA |

Safety & Health

- Safety

Addition curing ThermoBond 3830 silicone adhesive contains neither toxic nor corrosive substances that might require special handling precautions. General hygiene regulations should be observed.

Storage & Handling

- Storage

ThermoBond 3830 has a shelf life of at least 6 months when stored below 21°C in the originally sealed container. The 'Best use before end' date of each batch appears on the product label. Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.