Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Characteristics

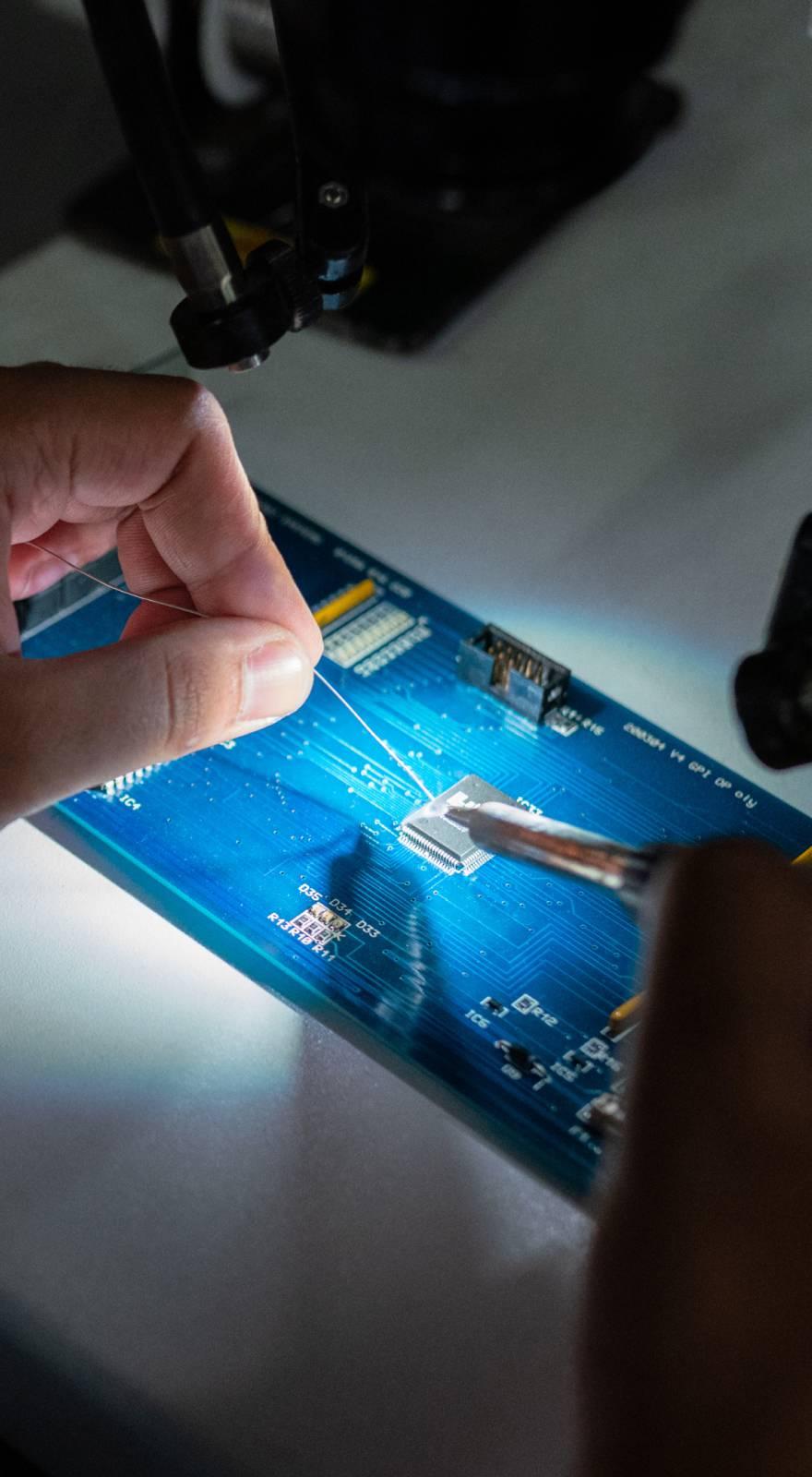

Characteristics EP1611 is a flexible epoxy adhesive for sealing or encapsulating electronic devices. It is a twocomponent, non-slump, rubber-toughened formulation that cures at elevated temperature to provide strong bonding to various plastics, ceramics and metals. The flexibility reduces thermal stress and provides better thermal cycle performances. EP1611 is dispensable.

- Special Features & Benefits

- Flexibility for stress reduction

- Fast cure and room temperature curable

- Flowable for potting / encapsulation

- Strong fracture toughness

- Strong bonding to various substrates

- Low bleeding, low volatile

Applications & Uses

- Applications

- Application Area

- Cure Method

- Typical Applications

- Bonding / sealing of electronic components

- Encapsulate parts, cavities

- Bonding of plastics, ceramics and metals

- Attach PCBs, base plates, components

- Seal lids, covers, housings, connectors

- Vibration dampening

- Thermal stress coupling

- Aerospace & Automotive electronics

- Semiconductor & Telecommunications

- Processing Instruction

- Only components A and B with the same lot number may be processed together! For the package in a container (not in a cartridge), to ensure homogeneity of the material, the components must be stirred thoroughly before they are removed or processed in order to uniformly disperse any fillers that might have settled during storage. For potting applications, it is recommended to warm the parts to ~60°C, and then do potting. Any possible air bubbles in mixing or potting process can be removed by vacuum.

- We recommend running preliminary tests to optimize conditions for the particular application. Comprehensive processing instructions can be obtained by contacting directly to United Adhesives, Inc.

Properties

- Color

- Typical Properties

- Typical Cured Properties

| Value | Units | Test Method / Conditions | |

| Density (As Mixed) | 1.2 | Gram /cc | ASTM D792 |

| Mixing Ratio (A:B) | 1:1 | By volume | - |

| Viscosity (As Mixed At 25°) | 60000.0 | cps | ASTM D2196 |

| Value | Units | Test Method / Conditions | |

| Adhesion (Al/Ai Lap Shear) | min. 1500 | Psi | ASTM D1002 |

| Coefficient Of Thermal Expansion | 150.0 | ppm/°C | IPC-TM-650 |

| Cure Time (25°C) | 10 - 12 | hr | Durometer |

| Cure Time (85°C) | 60.0 | min | Durometer |

| Dielectric Constant (100 Hz) | 4.0 | - | ASTM D150 |

| Dielectric Strength | min. 400 | Volt/mil AC | ASTM D149 |

| Elongation | 50.0 | % | ASTM D638 |

| Hardness | 60.0 | Shore A | ASTM D2240 |

| Pot/Work Life (After Mixed Up, 25°C) | 0.5 | hr | Viscosity double |

| Temperature Usage | -80 to 150 | °C | TGA |

| Tensile Strength | 8.0 | Mpa | ASTM D638 |

| Volume Resistivity (24°C) | min. 10E+12 | Ohm-cm | ASTM D257 |

Safety & Health

- Safety

General hygiene regulations should be observed.

Storage & Handling

- Storage

EP1611 has a shelf life of at least 12 months when stored in ambient in the originally sealed container. The 'Best use before end' date of each batch appears on the product label. Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.