Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Characteristics

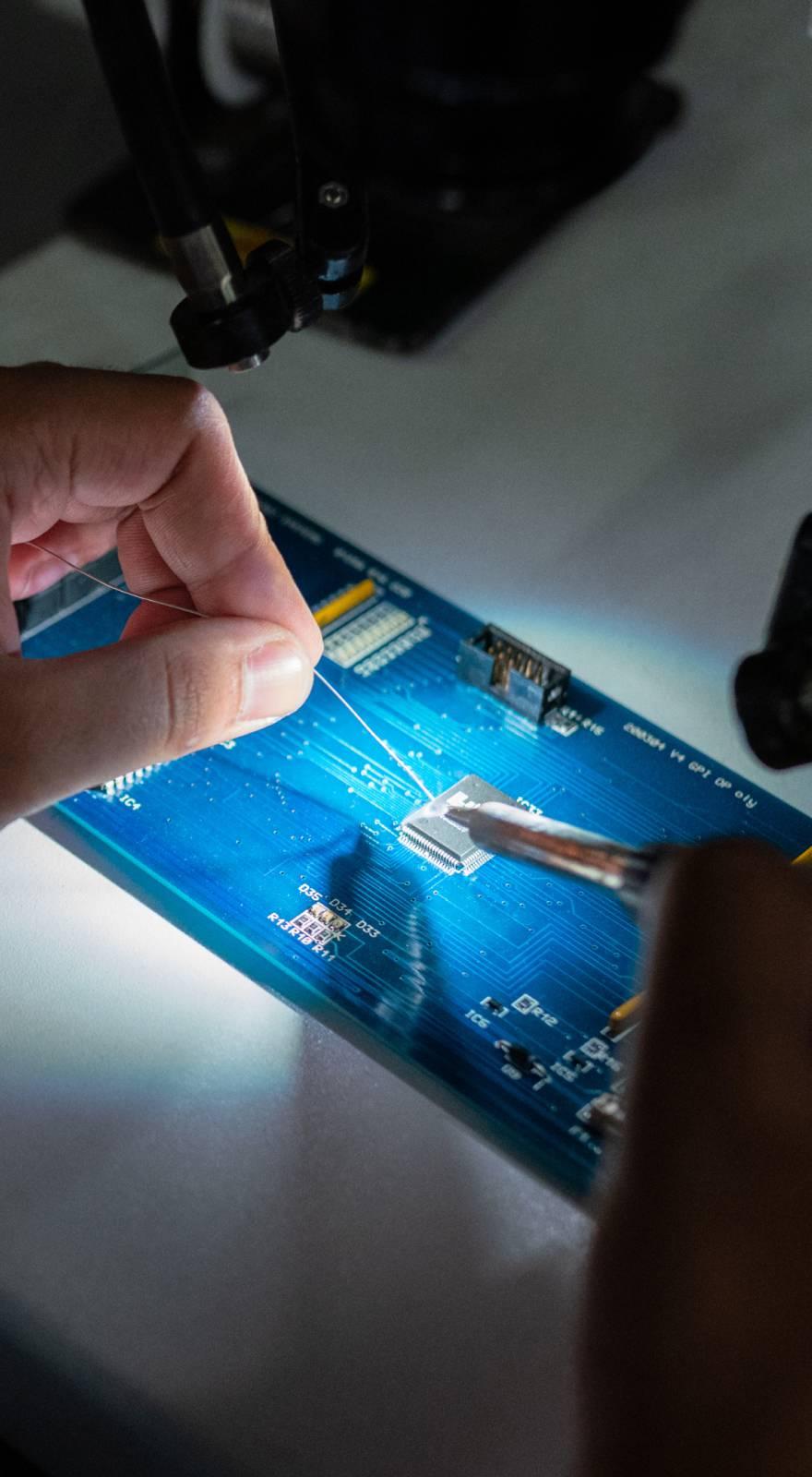

OE1581 is one component water clear optically transparent epoxy adhesive / potting compound for L.E.D. encapsulating, fiber optics, clear potting, or any optical and electronic applications. After cured at elevated temperature, it forms a transparent, colorless solid with strong bonding to various substrates such as metals, silicon, flip chip, BGA, ceramics, LTCC, Al, Cu, stainless steel, etc. It is formulated with anti-ultraviolet protecting to minimize yellowing over time. It also provides bubble free and glass smooth finish.

- Special Features & Benefits

- Water clear optical transparency

- One component and ready to use

- High bonding strength

- Low bleeding, low volatile

- Low ionic content

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Typical Applications

- Opto-Electronic Applications

- LED Glob-Top Encapsulating

- Semiconductor and Telecommunications

- Optical Lens and IR Lens

- Fiber Optical Potting or Sealing

- Lens and Prism Bonding

- Bonding or Potting of Medical Devices

- Adhesive for Endoscopes or Light Guides

- Structural Bonding or Potting

- Processing Instruction

- Please let the compound thaw at room temperature before apply. Thawing time is typically 10 to 30 min depending on container size. Longer thawing time may need for larger size container. Any possible air bubbles in processing can be removed by applying vacuum.

- We recommend running preliminary tests to optimize conditions for the particular application. Comprehensive processing instructions can be obtained by contacting directly to United Adhesives, Inc.

Properties

- Color

- Typical Properties

- Typical Cured Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.05 | Gram /cc | ASTM D792 |

| Viscosity (As Mixed At 25°) | 3470.0 | cPs | ASTM D2196 |

| Value | Units | Test Method / Conditions | |

| Adhesion (Avai Lap Shear) | min. 800 | Psi | ASTM D1002 |

| Coefficient Of Thermal Expansion (Greater Tha Tg) | 120.0 | ppm/°C | IPC-TM-650 |

| Coefficient Of Thermal Expansion (Less Than Tg) | 60.0 | ppm/°C | IPC-TM-650 |

| Compress Strength | 150.0 | Mpa | ASTM D695 |

| Cure Time (125°C) | 30.0 | Min | DSC |

| Cure Time (85°C) | 2.0 | Hr | DSC |

| Dielectric Strength | min. 500 | Vol/mil AC | ASTM D149 |

| Flexible Strength | 120.0 | Mpa | ASTM D790 |

| Hardness | 70.0 | Shore D | DMA |

| Pot / Work Life (After Thawing, 25°C) | 8.0 | Hr | Viscosity double |

| Refractive Index (25°C) | 1.564 | - | ASTM D542 |

| Temperature Usage | -80 to 180 | °C | TGA |

| Glass Transmission | 75.0 | °C | DMA |

| Transmittance (360 nm to 1000 nm) | 95 - 99 | % | ASTD D1003 |

| Volume Resistivity | min. 10E+12 | Ohm-cm | ASTM D257 |

Safety & Health

- Safety

General hygiene regulations should be observed.

Storage & Handling

- Storage

OE1581 has a shelf life of at least 6 months when stored at –40°C in the originally sealed container. The 'Best use before end' date of each batch appears on the product label. Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.