Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

Features & Benefits

Applications & Uses

- Applications

- Application Area

- Application

- Maintains bond strength after 24 hr. cure, resists wafer drop & chipping

Properties

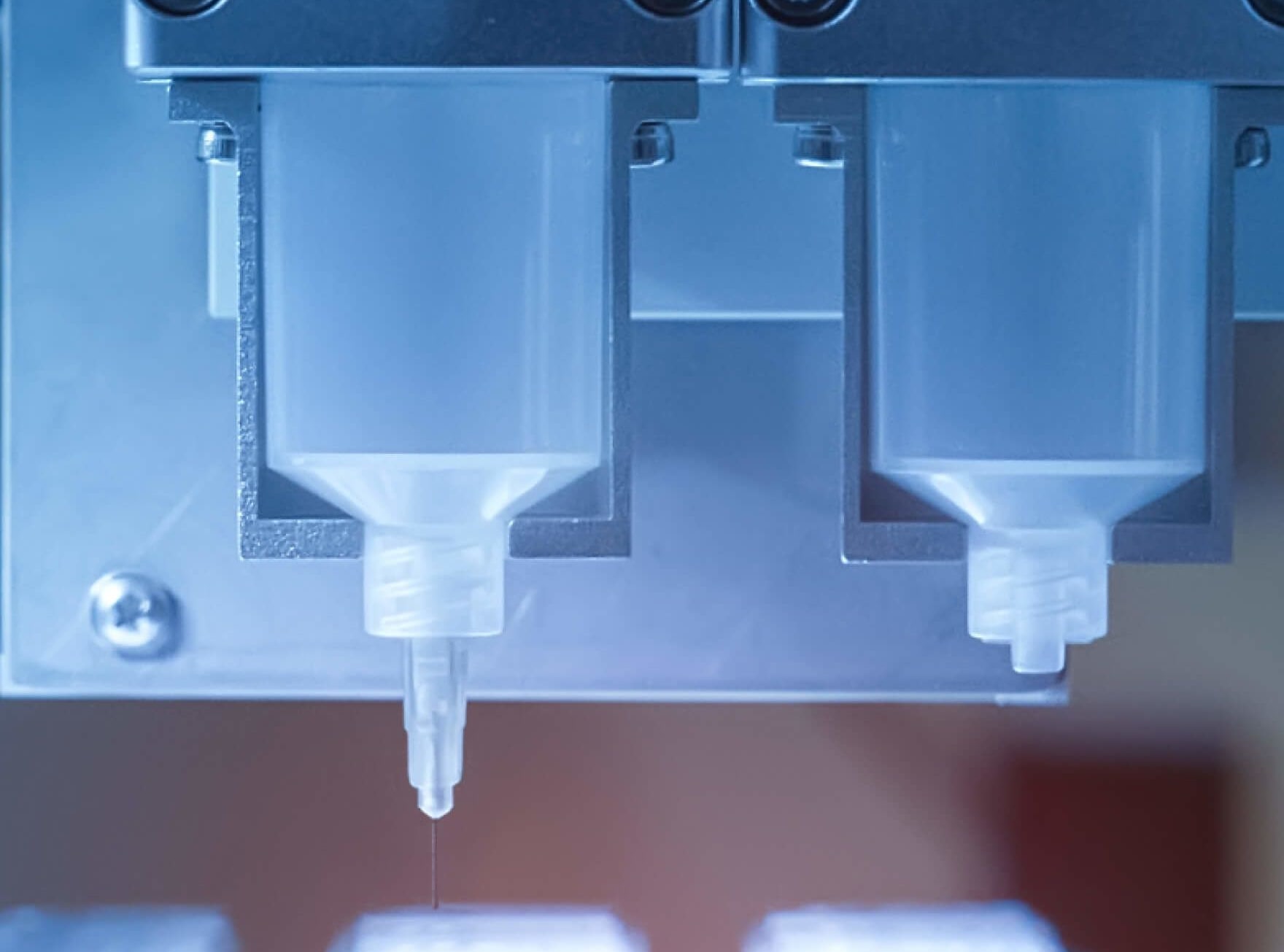

- Component A

- Component B

- Mixed System Properties

- Note

¹Gel Time condition 100 g @ 77ºF (25ºC). Setup time, solidification time.

²Cure Time conditions @ 77ºF (25ºC) Time needed prior to ingot slicing, recommended as starting point.

³Glass Transition Temperature using DSC Method

⁴Working Time, 50g @ 77ºF (25ºC), recommended maximum time.

⁵Typical minimum value only applicable to Valtech test method, not as specification, not to compare to other test methods.

| Value | Units | Test Method / Conditions | |

| Viscosity (25°C) | 30000 | cps | — |

| Specific Gravity | 1.52 | — | — |

| Mixing Ratio (By Weight) | 2 | — | — |

| Value | Units | Test Method / Conditions | |

| Viscosity (25°C) | 30000 | cps | — |

| Specific Gravity | 1.34 | — | — |

| Mixing Ratio (By Weight) | 1 | — | — |

| Value | Units | Test Method / Conditions | |

| Gel Time¹ | 12 | minutes | — |

| Cure Time² | min. 4 | hrs | — |

| Working Time⁴ | min. 5 | minutes | — |

| Hardness | 82 | Shore D | — |

| Bond Strength⁵ (4 hrs) | 1000 | psi | — |

| Bond Strength⁵ (8 hrs) | 1800 | psi | — |

| Glass Transition Temperature³ | 30 | °C | — |

| Slurry Compatibility | PEG | — | — |

| Slurry Compatibility | PEG/Water | — | — |

| Slurry Compatibility | DEG/Water | — | — |

| Slurry Compatibility | Aqueous | — | — |

Technical Details & Test Data

- Demounting

Epoxy System Debonding Solution Temperature(°C) Time Required AD5038-A

AD5038-BAcetic Acid min. 30 max. 30 Citric Acid (>10% by wt.) min. 50 max. 30 VALTRON® DP164 (>12% by vol.) min. 50 max. 30