Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Applications

Technical Details & Test Data

- Test Data

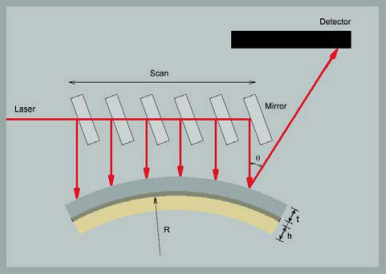

Bonding of materials with mismatched CTE’s can result in bending. This can be measured as radius of curvature through a technique called laser inferometry. Figure 1 illustrates the technique.

Figure 1. Radius of curvature by laser inferometry.

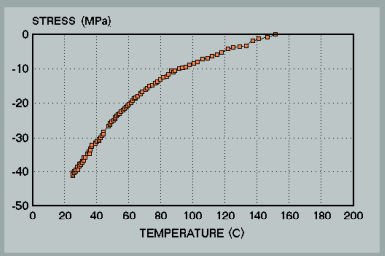

In a comparative test, a 250 x 250 mil silicon die is bonded to a copper leadframe. Using a conventional silver-filled epoxy, the radius of curvature of the die was 1000 mm at room temperature. Bonded with TC-601.1, radius of curvature was 100,000 mm. Both adhesives are cured at 150oC. Bending stress can be calculated from the radius of curvature. Figure 2 shows bending stress of the die bonded with silver-filled epoxy. There is no curvature or stress at the 150oC cure temperature. As the assembly cools, curvature and stress increase.

Figure 2. Bending stress with silver-filled epoxy.

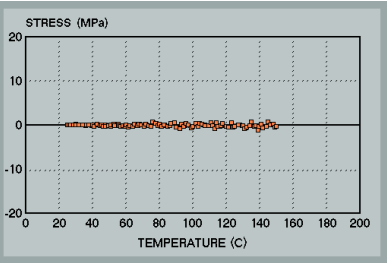

Figure 3 shows bending stress of the die bonded with TC601.1. The differential expansion of the two substrates is fully absorbed by the adhesive and both the die and the substrate remain flat and stress free over the entire temperature range.

Figure 3. Bending stress with TC-601.1