- Polymer Name:Polyamide 12 (PA 12)

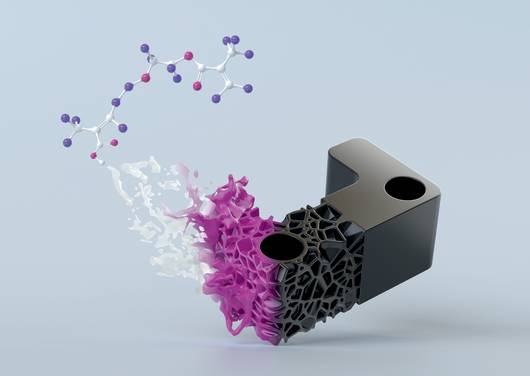

- Processing Methods:High Speed Sintering (HSS), Selective Laser Sintering, Powder Bed Fusion (PBF), Multi Jet Fusion (MJF), 3D Printing

- End Uses:Industrial Parts, Automotive Applications, Aerospace Applications, Medical/Healthcare Applications

- Features:Chemical Resistant, Consistent High Quality, Smooth Surface Finish, Highly Versatile, Excellent Mechanical Strength, Grease Resistant, Outdoor Durability, High Temperature Resistance, Oil Resistant, Solvent Resistant, Impact Resistance, High Performance, Good Processability, Food Contact Acceptable, Excellent Surface Properties, UV Resistant, Durable, High Strength

INFINAM® PA 6001 P is a food contact-acceptable powder designed for 3D printing. It boasts remarkable characteristics such as chemical resistance, consistently high quality, durability, excellent mechanical strength, oil resistance, excellent surface properties, good processability, high strength, and high-temperature resistance. Additionally, it is UV-resistant. This versatile material serves various industries, including aerospace, automotive, and medical applications.