Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Components

(2) Part A - Epoxy/Silver Part B - Hardener/Silver

- Consistency

Viscous, Thixotropic Paste

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Application Area

- Applications

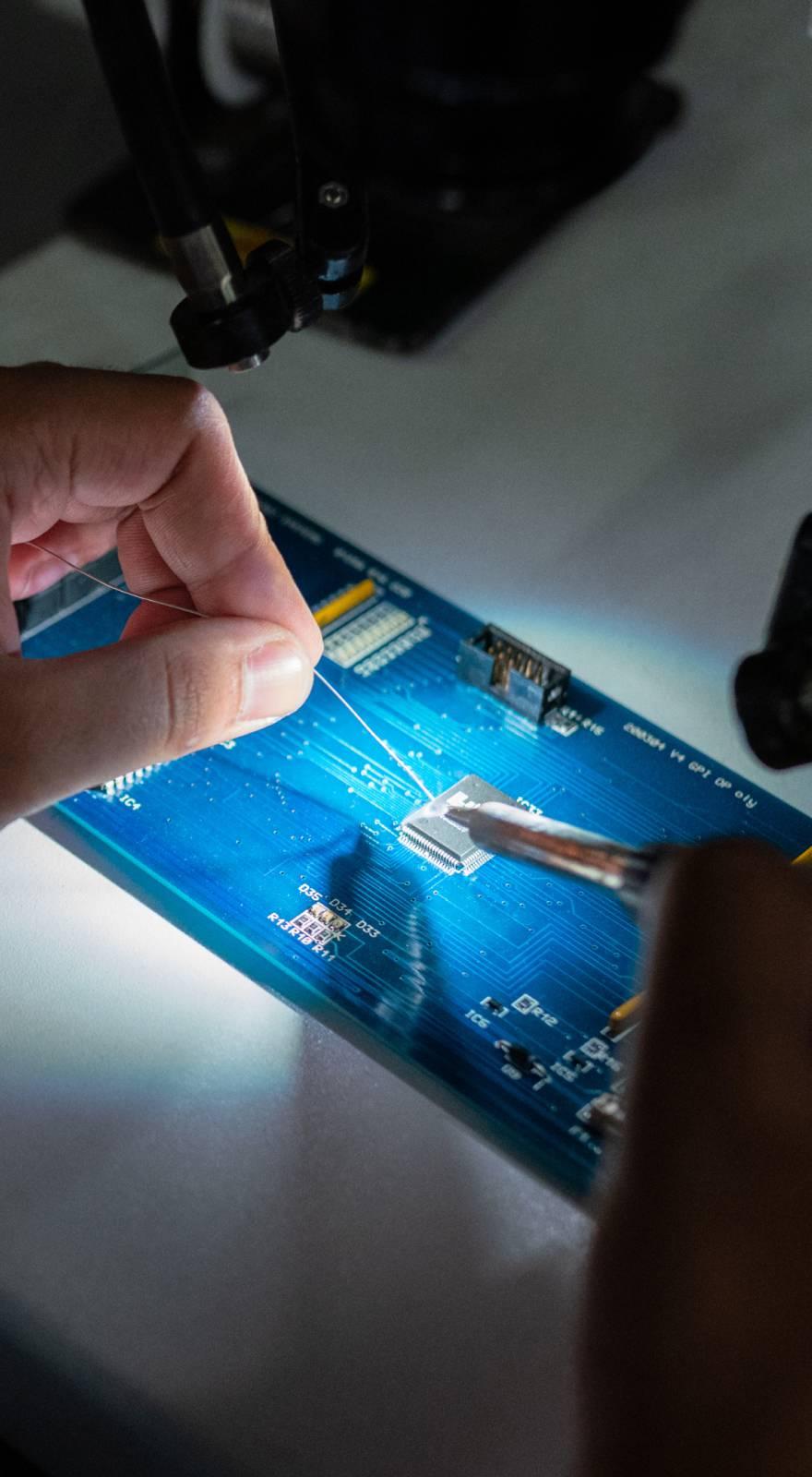

- Printed circuit board repairs

- Electrical soldering replacement

- Chip bonding

- Die attachment

- Static discharge/grounding

- Thermal dissipation

- Usage as a general electrically conductive cement for heat sensitive components

- Instructions

- Be sure that all surfaces to be bonded or coated with 5902 silver epoxy are clean, dry, and free of any grease or oil.

- Thoroughly mix equal amounts (by weight or volume) of Part-A and Part-B. Typical mixing times for small batches up to 5 grams is approximately two to three minutes.

- Since 5902 silver epoxy is designed to be a “Room Temperature Curing Adhesive,” it is recommended that applications be made within 1 hour of mixing. After this time the material will exhibit drastic increases in viscosity.

- For cleanup of uncured material use acetone, isopropyl alcohol, or MEK.

- Curing Schedule

24-36 Hours at 25°C or 10 Minutes at 80-100°C

- Mix-Ratio

1:1 (by weight or volume)

- Pot Life

30-60 Minutes at 20-25°C (3-5 gm mass)

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Silver Content | 85.0 | % | - |

| Specific Gravity | 4.1 | - | - |

| Volume Resistivity | max. 0.005 | ohm-cm | - |

| Thermal Conductivity (in/F² hr °F) | 11.0 | BTU | - |

| Hardness | min. 70.0 | Shore D | - |

| Tensile Lap Shear | min. 70-140 | kgm-cm² | - |

| Service Temperature Range | -55 - (+)150 | °C | - |

Storage & Handling

- Shelf Life

Six months at room temperature, sealed, unmixed