Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Thinner

- Carbitol Acetate

- Technologies

- Components

Single - requires no weighing

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Application Area

- Application Method

- Applications

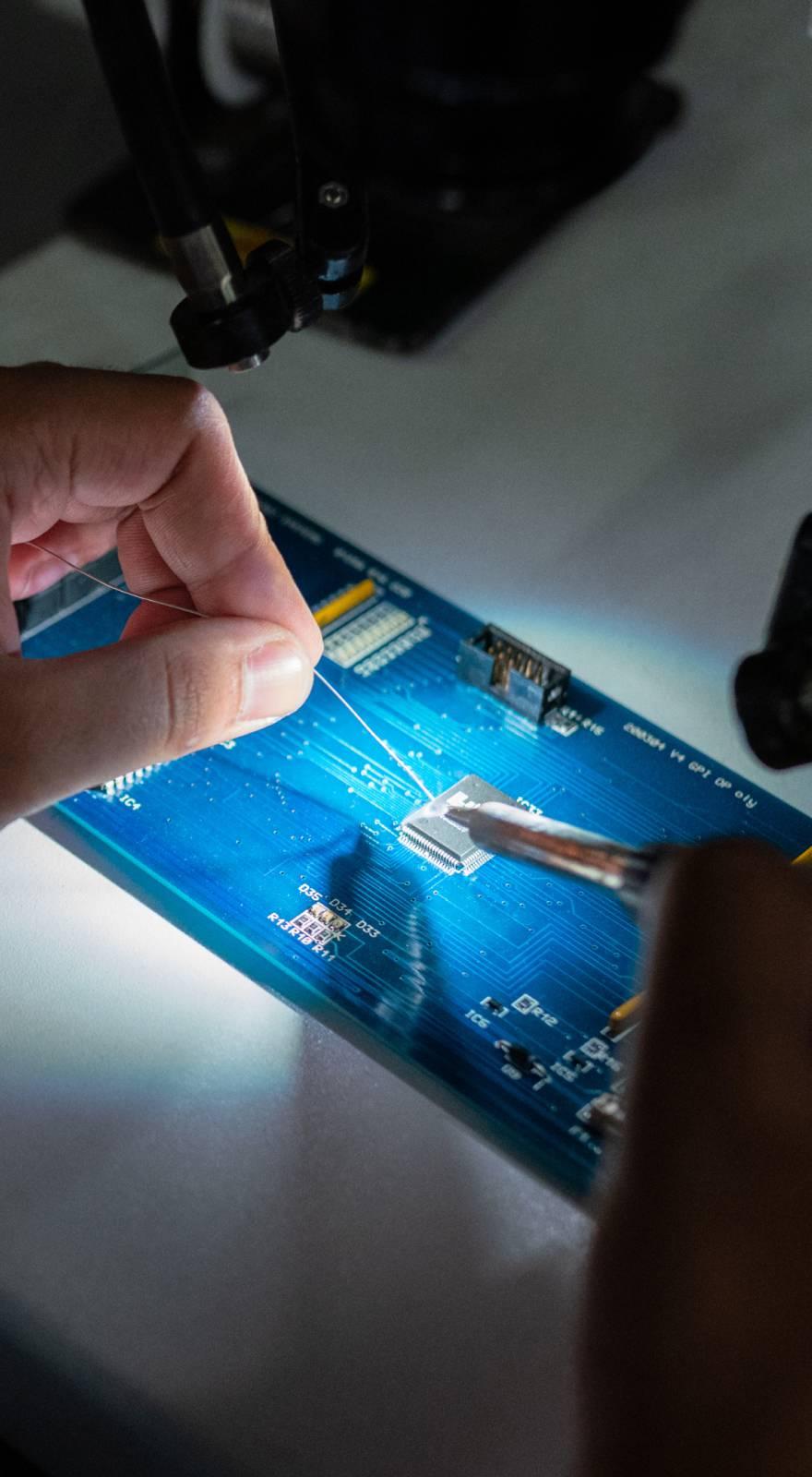

- Printed circuit board repairs

- Electrical soldering replacement

- Chip bonding

- Die attachment

- Static discharge/grounding

- Windshield bus bars

- Usage as a general electrically conductive cement for heat sensitive components.

- Instructions

- Be sure that all surfaces to be bonded or coated with 5978-14 silver epoxy are clean, dry, and free of any grease or oil.

- Paste should be mixed thoroughly before use.

- Materials may be applied via screen printing, syringe, or spatula.

- For optimum results, either of the above cure schedules should be observed.

- For cleanup of uncured material use acetone, isopropyl alcohol, or MEK.

- Cure Schedule

Drying 20 Minutes at 65°C (optional*)

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Silver Content | 78.0 | % | — |

| Specific Gravity | 4.0 | — | — |

| Viscosity (Brookfield RVT, Spin #7, 20 rpm, 25°C) | 20-50 | Kcps | — |

| Volume Resistivity | max. 0.001 | ohm-cm | — |

| Thermal Conductivity (in/F² hr °F) | 11.0 | BTU | — |

| Hardness | min. 70.0 | Shore D | — |

| Lap Shear | min. 1,200 | psi | — |

| Service Temperature Range | -55 - (+)175 | °C | — |

Storage & Handling

- Shelf Life

Twelve months at 25°C (Sealed Container) * Prints of 5978-14 may be dried, stored, and cured at a later time. The material can be re-liquified @ 120°C for placement of chips if drying step is kept under 65°C.