Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- CAS No.

- 55406-53-6

- EC No.

- 259-627-5

- Technologies

- Product Families

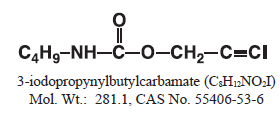

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Fluids & Lubricants Features

Applications & Uses

- Applications

- Fluids & Lubricants Type

- Coating Type

- Fluids & Lubricants End Use

- Ink & Toner Type

- Use Level

- 0.05 - 0.625% (Adhesives and Caulks (wet stage)), 0.05 - 2.5% (Textiles (i.e. carpeting, canvas, cordage), 0.25 - 2.0% (Paints and Stains)

- Applications

PAINTS AND STAINS

Generally, 0.3-0.5% of active material by weight of total formulation will protect against mildew growth. Where climates are ideal for mildew growth, up to 1.0% of active component

should be used. Interior paints usually would require levels of 0.1-0.3% of active material on total formulation weight. In stains where protection against mold and staining fungi is required, 0.3-0.4% of active material is recommended. When formulating with IPBC powder, the material should be solubilized in a suitable polar solvent before it is added to the formulation. Note: IPBC based products have been associated with irreversible yellowing of the dry film in some formulations, especially those products containing resins based on styrenated polymers. The propensity for yellowing of any new paint formulation (especially white paints) should be thoroughly evaluated when using IPBC-based products.METALWORKING FLUIDS

OMACIDE™ IPBC 100 Industrial Fungicide is effective in inhibiting the growth of fungi in aqueous metalworking, cutting, cooling and lubricating fluids. Up to 1000 ppm of active ingredient can be used in the diluted fluid. The amount required in the concentrate will depend on the end use dilution. For example, if the desired concentration of the active component in the diluted fluid is 100 ppm, and the end use dilution of the concentrate is 5%, then 0.2% concentration of OMACIDE IPBC Industrial Fungicide should be added to the concentrate (100 ppm/0.05 = 2,000 ppm or 0.2%). OMACIDE IPBC Industrial Fungicide can be added directly to soluble oil, and semi-synthetic metalworking fluid concentrates. It can be premixed into petroleum oil, or added at the end of the formulation. While not necessary, slight heating (110-130F) will speed the dissolution. OMACIDE IPBC Industrial Fungicide is compatible with most soluble oil and semi-synthetic metalworking fluids, however preliminary physical and chemical compatibility testing is recommended prior to commercialization.ADHESIVES

OMACIDE IPBC Fungicide prevent growth of fungus in both the wet product and dry film. Use levels for adhesives and caulks are 0.02-0.25% active material on total formulation weight. When using the fungicide powder, the product should be added to a polar organic solvent before adding to vehicle components.TEXTILES

Canvas, carpet, shower curtains, and boat covers can be protected against mildew by adding levels of 0.02-1.0 % (on an active component basis). These products are suitable for use in both solvent borne and aqueous emulsions products used in coatings and dyes typical in textile materials processing.

Properties

- Physical Form

- Appearance

- Pale yellow to amber-colored liquid

- Odor

- Pungent Aromatic

- Typical Physical Properties

- Physical Properties

- Composition

- Specifications

- Solubility

- Minimum Inhibitory Concentrations (MIC)

Table 1:

Molds OMACIDE IPBC, ppm

Active IngredientAspergillus niger 4 Aureobasidium pullulans <2 Chaetomium globosum <2 Gliocladium virens <2 Penicillium pinophilum 4 Fusarium sp. 8 Yeast Candida albicans <2

| Value | Units | Test Method / Conditions | |

| Boiling Point | 160 (320) | °C (°F) | — |

| Specific Gravity (at 20°C) | 1.16 - 1.17 | — | — |

| Value | Units | Test Method / Conditions | |

| Decomposition Temperature | 180 (356) | °C (°F) | by DSC (after solvent removal) |

| Density | 9.70 (1.16) | lb/gal (kg/L) | — |

| Evaporation Rate (butyl acetate = 1) | max. 1 | — | — |

| Freezing Point | max. 0 (max. 30) | ºC(ºF) | — |

| Solubility in Water | Emulsifiable | — | — |

| Vapor Density | min. 1 | — | Air = 1 |

| Vapor Pressure | max. 3 | mm Hg | — |

| Volatiles (by Weight) | 60 | % | — |

| Value | Units | Test Method / Conditions | |

| Dipropylene Glycol | 20 | % | — |

| DMSO9 | 15 | % | — |

| High Flash (Naphtha) | 25 | % | — |

| IPBC | min. 40 | % | — |

| Value | Units | Test Method / Conditions | |

| Color | max. 9 | Gardner | — |

| Value | Units | Test Method / Conditions | |

| Alkanolamines | 30 | % | — |

| Alkoxylated Linear Alcohol | 20 | % | — |

| Diethylene Glycol | 30 | % | — |

| Dipropylene Glycol | 40 | % | — |

| Ethoxylated Alkylphenol | 30 | % | — |

| Ethylene Glycol | 5 | % | — |

| Ethylene Glycol Monobutyl Ether | 45 | % | — |

| Polyethylene Glycol | 40 | % | 400, 600 MW |

| Propylene Glycol | 10 | % | — |

| Water Content | 0.015 | % | — |

| Water Insoluble Polyalkylene Glycol | 20 | % | — |

| Water Soluble Polyalkylene Glycol | 40 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability