Knowde Enhanced TDS

Identification & Functionality

- Pharma & Nutraceuticals Functions

- Technologies

Applications & Uses

- Applications

- Manufacturing Technology

Properties

Technical Details & Test Data

- Excipient for Hot Melt Coating

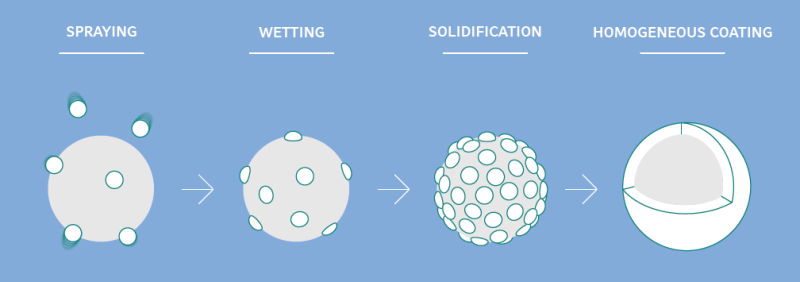

Hot melt coating (HMC) offers many advantages compared to conventional solvent-based coating technologies. HMC avoids drying times and makes potentially toxic and expensive organic solvents such as ethanol and isopropanol superfluous. The faster process results in higher batch throughput, leads to higher production volumes and increases productivity. HMC is also an effective method to mask the often bitter taste of active ingredients and produce products with a pleasant mouth feel.

- Polishing Agent for Sugar-Coated Tablets

If a shiny surface is requested for sugar-coated tablets, BonuWax® as a mixture of bee wax and carnauba wax can be used to achieve an excellent glossy finishing. Under the principle of friction, a brilliant gloss/shine will be realized, which leads to an esthetic valorization for sugar-coated tablets.

- The application amount of BonuWax® varies between 0,03–0,15% per batch – depending on the construction type and size of the coater.

- The polishing process needs 10–25 minutes, depending on the construction type and size of the coater.

- Before using BonuWax® for polishing, the sugar-coated tablets should be dry, but not dusty.

- During the polishing process the supply air shouldn’t be active. If the sugar-coated tablets begin to “slide”, supply air should be switched on. Sugar-coated tablets can be packed directly after the polishing process.

- Anti-Sticking Agent for Soft Gelatine Capsules

- BonuWax® is formulated with different natural waxes and is highly stable to provide excellent transparency, anti-sticking properties (effective separation) and enhanced mechanical stability/ flowability during processing and packaging. Waxed capsules also have higher resistance to external influences like humidity and temperature and are easier to swallow.

- Conventional soft capsules tend to get moisturized and become softer because of their hygroscopic nature when stored in high temperature and high humidity environment.

- As a consequence, adhesive property of surface of the soft capsules may be increased and sliding property of the soft capsules may be decreased, making packing and filling operations difficult, or the soft capsules may stick to each other or to the inner surface of the storage containers, and taking out of required amount of soft capsules may become difficult or the capsule membrane/ protective coating may be destroyed at the time of ingestion.

- Therefore, an anti-sticking agent which can offer excellent anti-sticking effect for soft capsules without impairing various properties such as water activity, disintegration property and safety even when the soft capsules are stored in high temperature and high humidity environment, is important.

- BonuWax® is easy-to-use in the drying tunnel by moistening the tissues and also in a conventional coating or polishing pan by manual pouring and polishing application.