Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Base Chemicals Functions

- CASE Ingredients Functions

- Technologies

Features & Benefits

- CASE Ingredients Features

- Features

- Color stability for better esthetics

- Easy to paint or finish for better looking products

- Extreme flexibility

- Low Tg and very high elongation

- Soft surface hardness

- High elongation for impact resistance

Applications & Uses

- Base Chemicals End Uses

- Applications

- Flexible 3D printing resins

- Flexibilizing agent for rigid coatings

Properties

- Uncured Properties

| Value | Units | Test Method / Conditions | |

| Density (25 °C) | 1.06 | g/cm3 | — |

| Pt-Co Color(APHA) | max. 50 | — | — |

| Pt-Co Color | max. 50 | APHA | — |

| Refractive Index (25°C) | 1.49 | — | — |

| Viscosity (25 °C) | 46000 | cP | — |

Technical Details & Test Data

- Typical Formulations

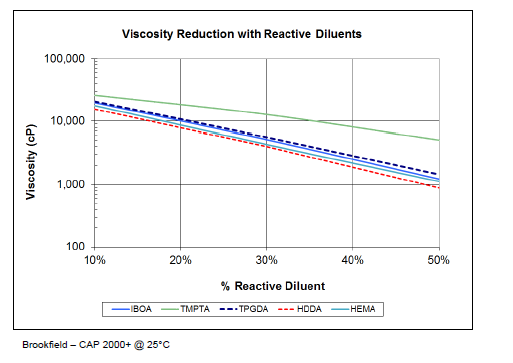

Test FormulationName I30 I50 TP50 TM50 H50 HE30 BR-345 70 50 50 50 50 70 IBOA 30 50 TMPTA 50 TPGDA 50 HDDA 50 HEMA 30 Omnirad™ 481 2 2 2 2 2 2 Viscosity, 25°C 5,500 1,400 4,800 1,500 900 4,200 Cured Mechanical Properties :

Property I30 I50 TP50 TM50 H50 HE30 Tensile Strength, psi 95 600 1,500 1,100 1,100 110 Elongation, % 120 400 2.6 19.4 6.5 290 Elastic Modulus, ksi 0.15 0.66 65 20 25 — Durometer Hardness 21A 32A 61D 36D 93A 25A Water Absorption (24hrs) 1.21 0.82 1.69 1.51 1.29 6.82 MEK Double Rubs (#) 4 4 10 5 6 10 Tg(DMA)=-42°C;Peak tan delta; cured with 2 phr of Omnirad™ 184 Adhesion Properties :

Substrate I30 I50 TP50 TM50 H50 HE30 Aluminum X X X Cold Rolled Steel X XX Glass X HDPE Polycarbonate X XXX XX X PET XX X X X XX PMMA XX X X PVC X X X Stainless Steel X X Recommended XX Highly Recommended XXX Strongly Recommended

- Viscosity Reduction with Reactive Diluents