Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

Features & Benefits

- CASE Ingredients Features

- Product Highlights

- Imparts incredible toughness

- Adheres to polymer films

- Low Tg

- Elastomeric

- Improves impact resistance

- Provides abrasion resistance

- Excellent cure response in LED conditions

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Recommended Application

- Thermoforming coatings and inks

- Impact modifier for coatings, 3D printing resins, and peroxide-cured composites

- Coatings for metal and plastic

Properties

- Uncured Properties

| Value | Units | Test Method / Conditions | |

| Pt-Co Color (APHA) | 35 | — | — |

| Pt-Co Color | 35 | APHA | — |

| Refractive Index (25°C) | 1.483 | — | — |

| Density (25°C) | 1.110 | g/cm3 | — |

| Viscosity (25 °C) | 69,000 | cP | — |

Technical Details & Test Data

- Typical Formulations

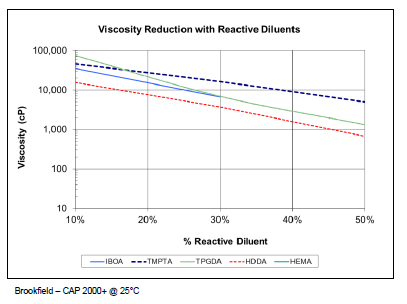

Test Formulation Name I30 I50 TM50 TP50 H50 HE30 BR-7432GI30

70 50 50 50 50 70 IBOA 30 50 TMPTA 50 TPGDA 50 HDDA 50 HEMA 30 Omnirad™ 184

2 2 2 2 2 2 Viscosity, 25°C (CAP2000+) 6.700

Incompatible

5.000 1.300 700 Did Not Cure Cured Mechanical Properties

Property I30 I50 TM50 TP50 H50 HE30 Tensile Strength, (psi, ASTM D882) 2.200

Incompatible 4.400

3.100

3.200

Did Not Cure Elongation (%, ASTM D882) 180 4.0 20 11.0 Elastic Modulus (ksi, ASTM D882) 7

170

90

85

Durometer Hardness 45D

83D

68D

72D Water Absorption, %(24 hrs)

0.66 0.66 0.67 0.57 MEK Double Rubs (#) 6 >200 29 121 Tg(DMA) = 40°C; Peak tan delta; cured with 2 phr of Irgacure® 184 Adhesion Properties

Substrate I30 I50 TM50 TP50 H50 HE30 ABS XXX Incompatible XXX XXX XXX Did Not Cure Aluminum Cold Rolled Steel Glass HDPE PET XX XX XX XX PMMA X X X XX Polycarbonate X XXX XXX XXX PVC XXX XXX XXX Stainless Steel X - Recommended, XX - Highly Recommended, XXX - Strongly Recommended

- Viscosity Reduction with Reactive Diluents

Safety & Health

- Safety Information

This product is intended for industrial use only. Keep out of the reach of children. Avoid breathing vapors. Avoid contact with skin, eyes, and clothing. Wear impervious gloves. Repeated or continuous skin contact with uncured material may cause irritation. Remove material from skin with soap and water. Never use organic solvents to remove material from skin and eyes.