Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

Features & Benefits

- CASE Ingredients Features

- Features

- Flexible dual cure oligomer

- Low viscosity

- Non yellowing

- Good adhesion to plastics and steel

- Excellent hydrolytic stability

- Good weatherability

Applications & Uses

- Markets

- Applications

- Cure Method

- Base Chemicals End Uses

- Coating Type

- Applications

- UV+Moisture cure applications for shadowed areas

- UV+Heat applications for dual cure properties

- Plastic and steel adhesives

- Dual cure 3D printing resins

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Avg. Acrylate Functionality | 1 | — | — |

| Density (at 25°C) | 1.13 | g/cm3 | — |

| Refractive Index (at 25°C) | 1.49 | — | — |

| NCO | 10 | % | — |

| Viscosity (at 60°C) | 2 | cP | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- UV + Moisture Cure Properties

Property UV Only Molsture Only UV+ Moisture Tensile Strength, psi** 70 300 4,400 Elongation, % ** 20 30 50 Elastic Modulus, ksi* 0.19 6.1 150 Durometer Hardness 57A 58A 68A Water Absorption, % (24 hrs) 0.35 N/A* 0.2 MEK Double Rubs (#) 7 23 70 Viscosity (cPs) 400 400 400 BR-990S2 diluted in 30% IBOA, cured with 2 phr of OmniradTM 184 (No photoinitiator in Moisture Only)

- For UV cured materials, two passes at 20 ft/min under Fusion D bulb, 2.1 inches.

- Moisture cure for 11 days at 25 C/50%RH, when NCO peak was gone on IR.

- Tensile strips are ~10 mils/250 microns

- UV + Heat Cure Test Formulation

Test Formulation Name Part A Part B PPG Diol (265 OH#) 38.3 BR-99052 79.25 IBOMA (fresh) 56.3 20.75 Omnirad™ 184 4.6 Omnirad™ 819 0.46 DBTDL 0.38 Viscosity, 25'C (CPs) 10 900 - UV + Heat Cure Properties

Property UV Only UV + Heat Tensile Strength, psi** 1,200 1,700 Elongation, 6** 95 110 Elastic Modulus, ksi* 11.9 14.5 Durometer Hardness 44D 470 Water Absorption, 9% (24 hrs) 0.52 0.49 MEK Double Rubs (#) 4 3 Viscosity (cPs) 140 140 Ratio of 1:1 Part A:Part B UV cured with OmniradTM 184 and 819

** Per ASTM D882

- Cured Mechanical Properties

Property I30 I50 TM50 TP50 H50 HE30 Tensile Strength, psi** 65 165 2,900 370 600 2 Elongation, %** 25 65 2.8 6.5 2.8 40 Elastic Modulus, ksi* 0.19 0.34 1000 6.5 20 40 Durometer Hardness 57A 80A 83D 46D 670 81D Water Absorption, % (24 hrs) 0.35 0.24 0.35 0.5 0.36 1 MEK Double Rubs (#) 7 10 >200 13 107 >200 Tg(DMA)=-8°C; Peak tan delta; cured with 2 phr of Omnirad® 184 ** Per ASTM D882 – Not Tested || Incompatible X Unable to Measure

- Adhesion Properties

Substrate I30 I50 TM50 TP50 H50 HE30 ABS ** * *** *** * Aluminum ** * * Cold Rolled Steel * *** * *** *** Glass * * HDPE PET * * *** *** *** PMMA * * * * Polycarbonate * * *** *** Polypropylene PVC * ** *** * *** Stainless Steel * * *** * Recommended ** Highly Recommended *** Strongly Recommended

- Typical Formulations

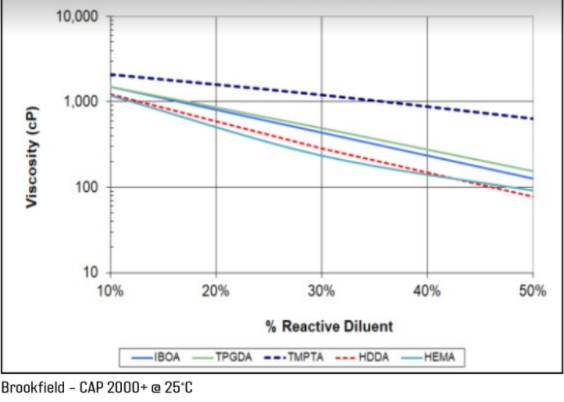

Test Formulation Name 130 160 TM50 TP50 H50 HE30 BR-146 70 50 50 50 50 70 IBOA 30 50 TMPTA 50 TPGDA 50 HODA 50 HEMA 30 Omniradw 184 2 2 2 2 2 2 Viscosity, 25C 400 130 600 160 80 240 * Brookfield – CAP 2000+ @ 25°C.

- Viscosity Reduction with Reactive Diluents

Safety & Health

- Safety

This product is intended for industrial use only. Keep out of the reach of children. Avoid breathing vapors. Avoid contact with skin, eyes, and clothing. Wear impervious gloves. Repeated or continuous skin contact with uncured material may cause irritation. Remove material from skin with soap and water. Never use organic solvents to remove material from skin and eyes.

For more information on the safe handling of this material, please refer to the Safety Data Sheet before use.

Packaging & Availability

- Packaging Type