Braskem America

About Us

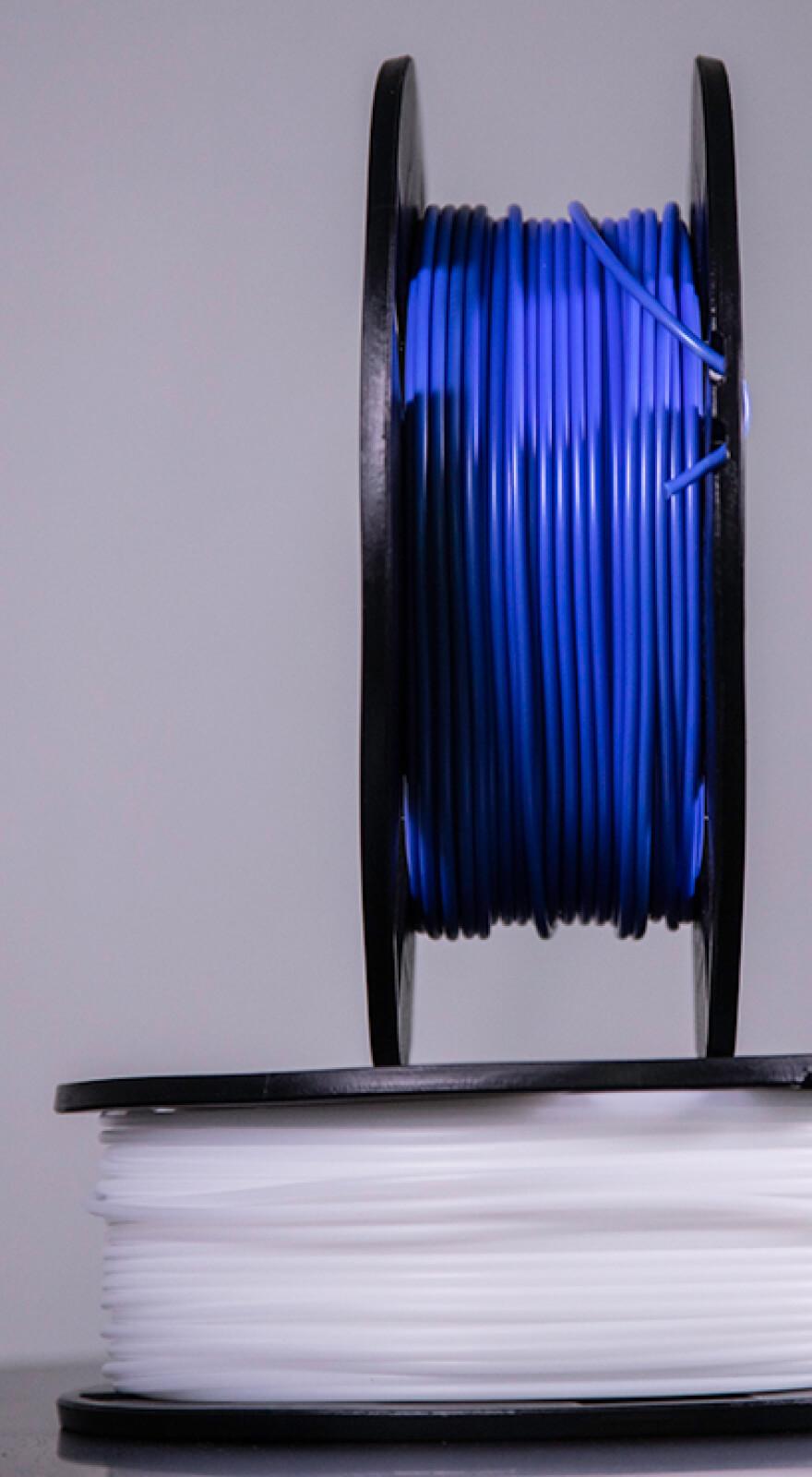

With a strategy centered on people and sustainability, Braskem is engaged in contributing to the value chain to strengthen the Circular Economy. Braskem’s almost 9,000 team members dedicate themselves every day to improving people's lives through sustainable solutions in chemicals and plastics. With its corporate DNA rooted in innovation, Braskem offers a comprehensive portfolio of plastic resins and chemical products for diverse industries, such as food packaging, construction, manufacturing, automotive, agribusiness, health and hygiene, and more. With 40 industrial units in Brazil, the United States, Mexico, and Germany, Braskem exports its products to clients in over 70 countries.

Braskem America is an indirect wholly owned subsidiary of Braskem S.A. headquartered in Philadelphia. The company is the leading producer of polypropylene in the United States, with six production plants located in Texas, Pennsylvania, and West Virginia, an Innovation and Technology Center in Pittsburgh, and a New Renewable Innovation Center in Boston focused on leveraging groundbreaking developments in biotechnology and advanced materials. For more information, visit www.braskem.com/usa.

Browse Products by Market

View All ProductsBrowse Products by Technology

View All ProductsMost Viewed Products

View All ProductsMost Viewed Brands

View All Brands