Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Features

- Less processing & fewer chemicals at lower cost

- Nano properties without being nano (imp for human contact)

- Viscosity flexibility allowing more applications & no gelling

- Better green story

- Nimble and flexible manufacturing options

- Close porosity

- Barrier

- Molded fiber

- Thicken

- Barrier

- Various Application Features

Paper & Board

- Lowering CO2 (moving from solvent based to water based)

- Replacing Plastic

- Reducing waste (recyclable)

- Reducing substances of high concern (no Fluorochemicals - PFAS)

- Improving barrier properties (oxygen, water, grease)

Paper & Board: Molding with Curran

- Wet-end blending of normal pulp & Curran

- Enhanced strength

- No "dusting" or "hairy" fibers on surface

- Higher density, lower porosity

- Shape retention & strength when wet

- Excellent barrier performance with thinner coating

- Both 3D molded packaging and flat paper/board

- For applications requiring high barrier, long shelf life and strength

- Recyclable, compostable, biodegradable

Paper & Board: - Coating with Curran

- Excellent moisture barrier for tough applications

- Very high oxygen barrier

- Strong grease/oil barrier for greasy foods

- Compostable at home

- Repulpable/recyclable on paper due to thin layers

- Good heat sealibility

- Food contact approved

Curran in Food

- Reduces sugar and fat in food

- Maintains texture & taste

- Natural emulsifies and thickener that does not gel

- Reduces other components in food and sauces, such as egg

- Helps reduce costs

Applications & Uses

- Applications

- Coating Type

- Applications

- Paper & Board

- Food

- Paints & Coatings

- Interior and exterior architectural paints

- Industrial coatings

- Plaster-type materials, including stucc

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Composition | Cellulosic Platelet | — | — |

| pH Value | 4.5 - 7 | — | — |

| Form | Granules | — | — |

| Active Content | 20±2 | % | — |

| Volatile Component | Water | — | — |

| Viscosity | 500-2000 | cPs* | — |

| Density | 1.07 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Key Properties

- Up to 90% reduction of coalescing solvents resulting in reduced odor and VOC

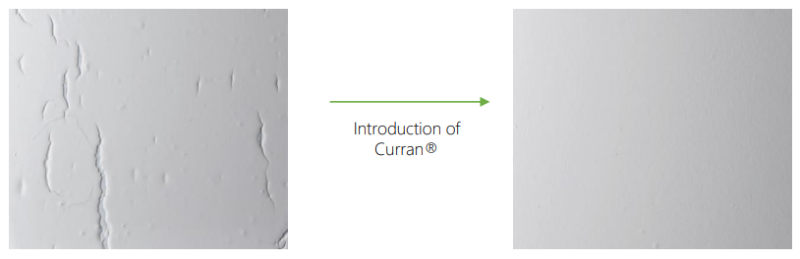

- Up to 50% reduction of micro cracking

- Up to 200% improvement of mud crack resistance Improved opacity resulting in up to 6% reduction in Titanium Dioxide

- Process Guidelines

Curran® Granules should be added at the dispersion/grind phase, ensuring there is sufficient water present for dispersion and rehydration (most common formulae will have sufficient water). For further information please request a copy of our incorporation video.

- Addition Levels

Recommended addition levels of Curran® Granules are between 1-3% (based on supplied form), optimum levels are determined through a series of laboratory tests. The ratios of Curran® to HEC may be altered for optimisation depending on the required key properties of the formulation.

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage Conditions

Store protection from frost and not above 40 °C. Opened containers must be closed again well since the product tends to form a skin.

- Handling & Storage

Before using this product please consult the Material Safety Data Sheet (MSDS) for information on safe handling and storage. Recommended storage conditions are a cool and dry environment. Once open, containers containing Curran® Granules should be re-sealed to avoid moisture loss. Commercially, Curran® is supplied in 15 Kg boxes .