Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- HII Features

- Product Highlights

- Longer lasting colors.

- Brighter whites-reduced graying of white fabrics.

- Preserves and protects fabrics and garments-reduced damage through the wash and reduces pilling.

- Outstanding results at low inclusion levels, even in concentrates.

- Tested and proven effective at wash temperatures from 15°Cto 40°C.

- No impact on softening performance.

- Reduces garment ironing time.

- Halal certified grade available.

- Performance Characteristics

Coltide Radiance is an innovative biopolymer with a modified backbone providing increased substantivity to fabric and fibers. Coltide Radiance actively shields the fabric throughout the washing and drying cycle, protecting garments and fibers from damage often identified as pilling, “cracking” of printed t-shirts and/or fibrillation of individual fibers.

This protection makes fabric and garments look like they have been washed half as often. Coltide Radiance has also been proven effective at protecting the color of a range of colored garments and keeping your white fabrics whiter, longer.

This novel performance additive allows your fabrics to look radiant for longer while maintaining their softness. All these benefits are gained at very low inclusion levels, making Coltide Radiance extremely cost effective in use.

Coltide Radiance Protects Your Brights and Whites

All garments were washed along with ballast with a commercially available laundry detergent and treated with a commercial concentrated fabric conditioner (28 ml/wash dosage) before being tumble dried.

The control garments were treated with a standard commercial fabric conditioner and the test garments were treated with the same fabric conditioner but containing 1% Coltide Radiance. The change in color was assessed visually and quantified using a reflectometer.

Color retention improved after only one wash. When washing white and colored fabric together, Coltide Radiance reduced graying and color deposition.

With Color Protection Seeing is Believing

In order to assess the protective properties of Coltide Radiance color retention was measured on garments washed on their own (denim jeans and black t-shirts) and together (mixed colored wash). The denim jeans and black t-shirts were chosen for testing as they show a high level of color fade. A mixed colored wash was tested in order to replicate more realistic washing conditions.

Coltide Radiance visibly improved retention of color in denim jeans and black t-shirts compared to garments washed without Coltide Radiance. In Images 1 and 2 compare garments washed 10 times with and without Coltide Radiance and unwashed samples. The garments washed with Coltide Radiance clearly retained more color.

Image 1: In testing, garments washed with Coltide Radiance clearly retained more color

Image 2: Black cotton t-shirts retained more color after 10 washes of Coltide Radiance

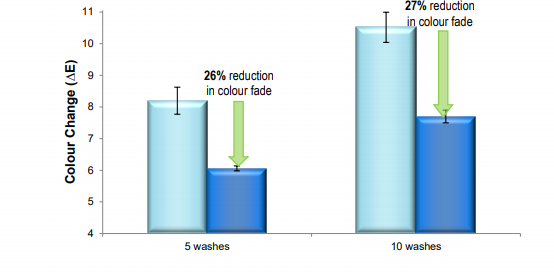

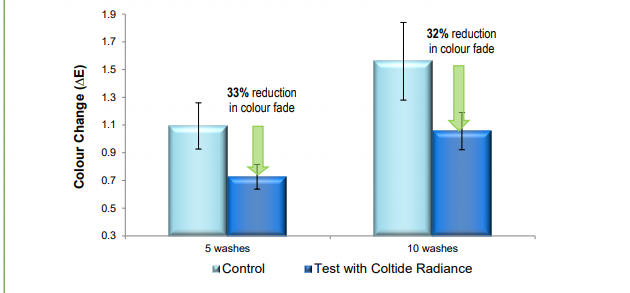

The improved color retention of the denim jeans and black t-shirts have been quantified at 26-27% and 33- 32%, respectively, after 5 and 10 washes when using Coltide Radiance compared to the control formulation. Consumers can usually easily perceive a visible difference in color of one E value. Color change can therefore be measured quantitatively using a reflectometer and a clear reduction in color fade can be observed in the denim jeans (Figure 1) and the black t-shirts (Figure 2) when using Coltide Radiance. After 10 washes using 1% Coltide Radiance the garments have the same color change as after only 5 washes with the control formulation – indicating that Coltide Radiance keeps garments newer for longer.

Figure 1: Color fade of blue denim jeans after 5 and 10 washes, with and without Coltide Radiance, compared to the initial color of the unwashed jeans

Figure 2: Color fade of black cotton t-shirts after 5 and 10 washes, with and without Coltide Radiance, compared to the initial color of the unwashed t-shirts

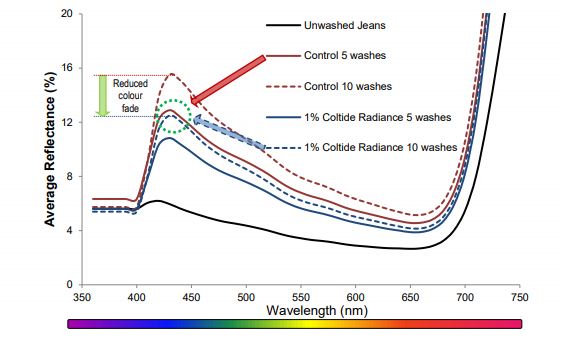

This data is enhanced by analyzing the reflectance data from the denim jean samples (Figure 3). Coltide Radiance helps preserve the original color of the jeans, a peak in the blue-violet region (blue lines). This is in contrast to the higher peaks observed in jeans washed without Coltide Radiance (red lines)

Jeans washed 10 times with Coltide Radiance have reduced color fade compared to the control formulation. The color fade is equivalent to the jeans washed only 5 times without Coltide Radiance – the clothes look like they have been washed half as often, increasing the life cycle of the garment.

Figure 3: Reflectance data for denim jeans samples

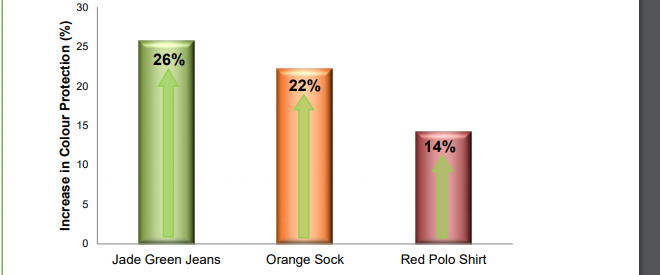

In addition to protecting single items such as denim jeans and black t-shirts Coltide Radiance also provides protection to a range of colored garments when washed together (Figure 4). Over 10 washes Coltide Radiance increased color retention by 14-26% for a range of colored items (jade green jeans, orange sock, red polo shirts) compared to a wash without Coltide Radiance.

Figure 4: Washing with Coltide Radiance improved color retention versus washing without

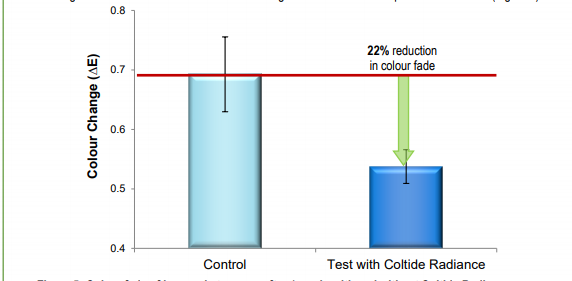

Coltide Radiance improves color retention from the first wash. A pair of burgundy trousers were quantified as showing a 22% reduction in color fade when using Coltide Radiance compared to the control (Figure 5).

Figure 5: Color fade of burgundy trousers after 1 wash, with and without Coltide Radiance

Reduced Graying of Whites - Whites Stay Whiter for Longer

The graying of fabric was measured on white fabric swatches and a mixture of white garments, replicating consumer wash conditions.

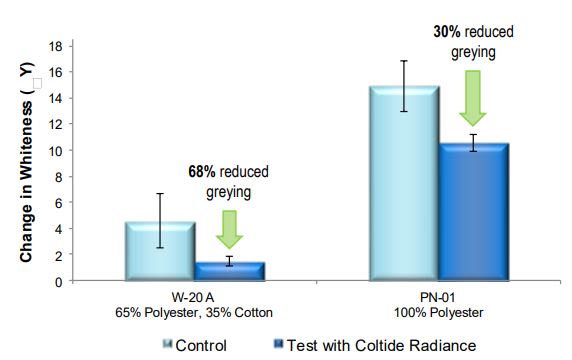

Initially the overall change in whiteness (graying) was measured on two types of fabric; polycotton (65% polyester, 35% cotton) and polyester swatches (W20-A and PN-01 respectively), after 5 washes with and without 1% Coltide Radiance (Figure 6). The use of Coltide Radiance resulted in 68% reduced graying of the polycotton fabric while a 30% reduction in graying was gained for the polyester fabric, compared to control formulations.

Figure 6: Overall change in whiteness (graying) of polycotton and polyester fabric swatches after 5 washes, with and without Coltide Radiance

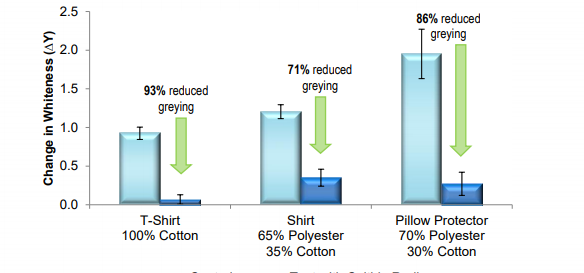

In order to replicate consumer washing conditions a mixture of white fabrics and garments were washed together. White t-shirts, shirts and pillow protectors were washed with and without Coltide Radiance and an outstanding improvement in fabric whiteness was identified when using Coltide Radiance, resulting in reduced graying of 71-93 % (Figure 7).

Figure 7: Overall change in whiteness (graying) of white t-shirts, shirts and pillow protectors after 10 washes, with and without Coltide Radiance

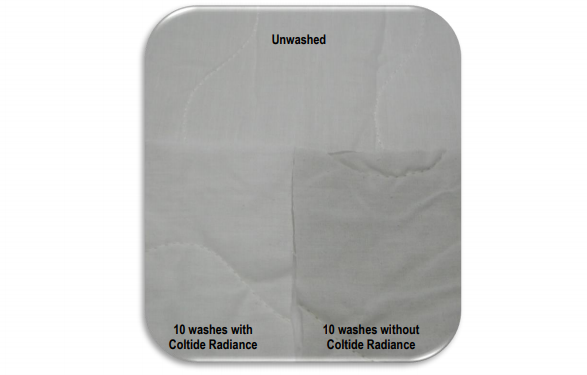

This difference can also be perceived visually by consumers. A blind consumer panel study was conducted assessing the pillow protectors washed 10 times with and without Coltide Radiance. 100% of participants chose the Coltide Radiance item as looking newer and brighter. Samples of the pillow protectors used in the testing can be seen in image 3 below.

Image 3: Visual difference in pillow protectors after 10 washes with and without Coltide Radiance

The Impact of Coltide Radiance on Washing Colored and White Items Together

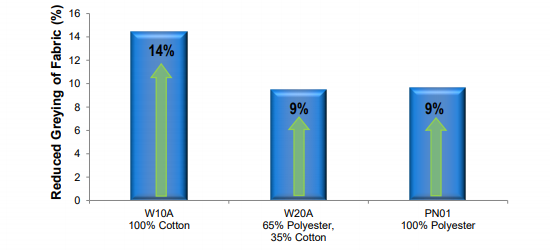

In order to assess color transfer a range of colored garments were washed with white fabric swatches and soil to replicate consumer conditions. The change in color and whiteness of the swatches were assessed quantitatively after 10 washes with and without Coltide Radiance.

A range of white fabric swatches (100% cotton, 65% polyester and 35% cotton, and 100% polyester) washed with Coltide Radiance showed reduced graying of 9 -14% was quantified compared to fabric washed without Coltide Radiance (Figure 8).

Figure 8: When washed with Coltide Radiance, a range of white fabric and polyester swatches showed reduced graying

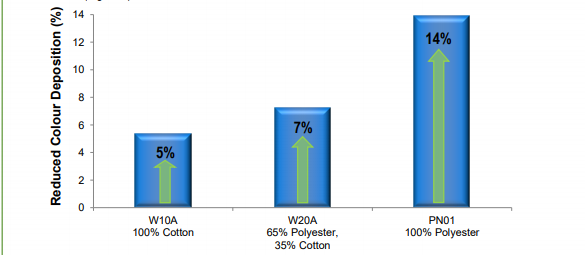

Reduced color deposition was quantified at 5-14% in a range of fabric swatches (100% cotton, 65% polyester and 35% cotton, and 100% polyester) when using Coltide Radiance compared to fabric washed without Coltide Radiance (Figure 9).

Figure 9: Reduction in color deposition (based on E) on white fabric swatches (range of cotton and polyester) when using Coltide Radiance compared to 10 washes without Coltide Radiance

Garment and Fiber Protection

Repeated washing and drying of clothes puts strain on the fabric resulting in fibrillation and surface fiber damage, reducing the life cycle of a garment. Examples include pilling of the fabric, “whitening” and fuzziness to the surface of your clothes and/or fibrillation of individual fibers when viewed under the microscope. Repeated washing can also cause "cracking" of printed patterns, resulting in garments looking worn and old. Coltide Radiance helps shield and protect garments and fibers, reducing the visual signs of stress and resulting in garments looking newer and more radiant for longer.

Visual Inspection

At a macroscopic level damage to garments can easily be identified by consumers on patterned t-shirts, by the printed pattern looking “cracked” and uneven. This can be observed in Image 3, where the bottom t-shirts look newer, despite being washed for the same number of cycles, compared to the t-shirt washed without Coltide Radiance (top images).

Image 3: Printed t-shirts washed 10 times with and without Coltide Radiance

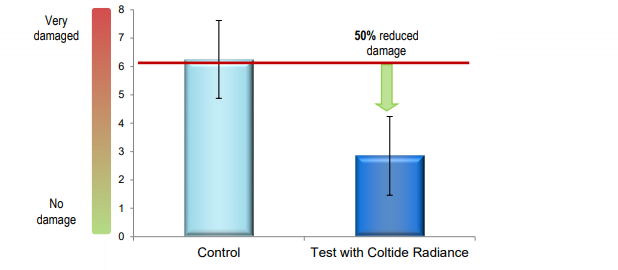

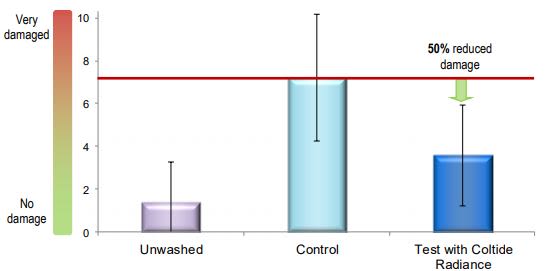

Image 3: Printed t-shirts washed 10 times with and without Coltide RadiancePilling is also a common visual sign of garment and fabric damage. Pillow protectors were washed 10 times with and without Coltide Radiance and a clear improvement in the number of pills was identified when using an inclusion level of 1%. A panel survey was conducted on the washed fabric, asking each individual to identify the item which looked brighter, newer and less damaged. All panelists independently identified the fabric washed with Coltide Radiance as having fewer pills, classifying the fabric as looking 50% less damaged than the control (Figure 10).

Figure 10: Panel study assessing damage to pillow protectors washed 10 times with and without Coltide Radiance. Participants were asked to rank the amount of damage to each item

The reduced number of pills when using Coltide Radiance can be seen in Image 4 below

Image 4: Pilling of pillow protectors after 10 washes with and without Coltide Radiance. Pills have been highlighted and the images are compared to an unwashed fiber sample

Optical Microscopy

When using optical microscopy fiber damage is often identified as “fuzziness” or whiteness to the garment and fabric.

In order to assess fiber damage panelists were asked to identify bundles of fiber/pills from a wide range of optical microscope images of unwashed pillow protectors and fabric washes 10 times with and without Coltide Radiance. Fabric washed with Coltide Radiance was assessed as having half the number of pills as fabric washed without Coltide Radiance (Figure 11).

Figure 11: Participants were asked to count the number of pills of unwashed pillow protectors and fabric washed 10 times with and without Coltide Radiance and rank the damage accordingly

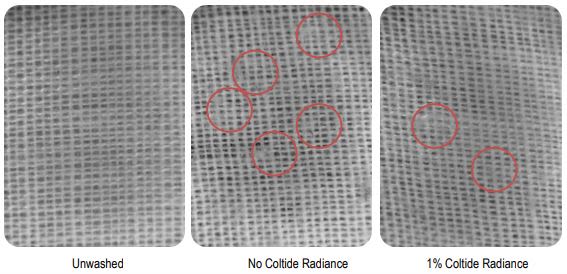

The extra “fuzziness” and bundles of fibers are apparent from samples washed without Coltide Radiance, compared to samples washed using 1% Coltide Radiance (Image 5). This highlights the protective benefits of the performance additive.

Image 5: Fiber damage to pillow protectors after 10 washes with and without Coltide Radiance. Fiber damage has been highlighted and is compared to an unwashed garment.

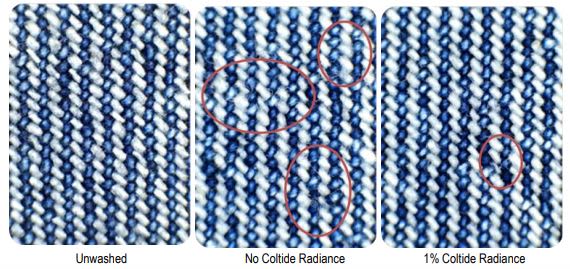

The protective benefits of Coltide Radiance are also apparent when viewing samples of denim jeans under an optical microscope (Image 6). Greater damage and whitening of the fabric is apparent from samples washed without Coltide Radiance compared to samples washed using 1% Coltide Radiance.

Image 6: Fiber damage of cotton denim jeans after 10 washes with and without the use of Coltide Radiance. Fiber damage has been highlighted and is compared to an unwashed garment

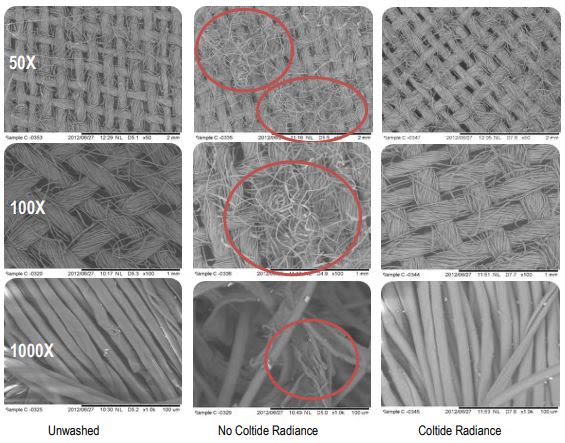

Scanning Electron Microscopy - SEM

Fabric and fiber damage are highlighted further at a microscopic level when using Scanning Electron Microscopy (SEM). At this level of magnification damage to the fabric is often identified as uneven, rough and twisted fiber formations and frayed and loose fiber strands.

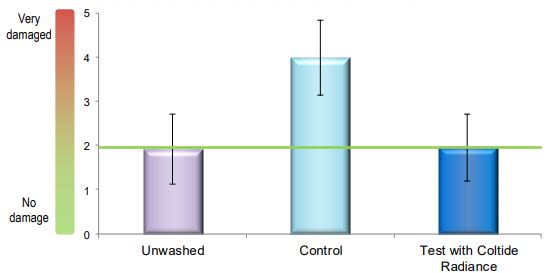

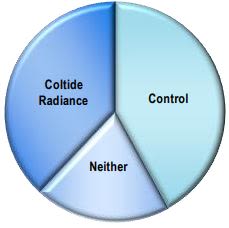

In order to assess the protective benefits of Coltide Radiance a panel study was conducted on a range of SEM images from pillow protectors taken at magnifications of 50X (fabric), 100X and 1000X (individual fibers) (Image 7). Panelists were asked to count the number of pills and rank the damage accordingly of unwashed pillow protectors and fabric washed 10 times with and without Coltide Radiance. Irrespective of whether looking at a fabric or a fiber level, no difference could be seen between unwashed items and those washed 10 times with Coltide Radiance (Figure 12).

Figure 12: Panel study assessing fabric damage from SEM images of unwashed pillow protectors and pillow protectors washed 10 times with and without Coltide Radiance

Figure 12: Panel study assessing fabric damage from SEM images of unwashed pillow protectors and pillow protectors washed 10 times with and without Coltide RadianceThe difference in these SEM images is highly apparent in Image 7 below; the fibers of pillow protectors washed with Coltide Radiance are very similar to the unwashed samples. The fibers are still keeping their straight and uniform woven pattern, even after 10 washes. The fibers of pillow protectors washed without Coltide Radiance are on the other hand very uneven, frayed and loose indicating severe damage.

Image 7: SEM images of pillow protectors washed 10 times with and without Coltide Radiance, compared to unwashed samples

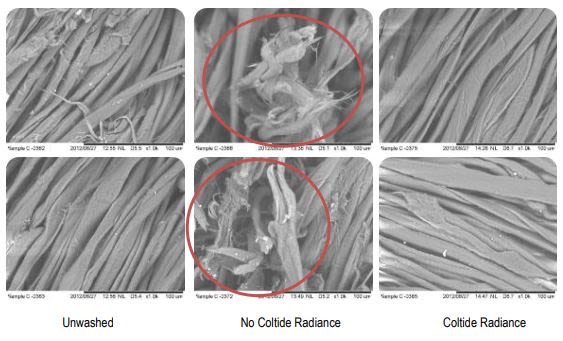

Image 7: SEM images of pillow protectors washed 10 times with and without Coltide Radiance, compared to unwashed samplesThe protective benefits of Coltide Radiance were stressed further when viewing SEM images of the denim jeans (samples taken from the leg fabric, seam and waistband). Increased fiber damage and breakage is clearly identified in samples washed without Coltide Radiance (Image 8). Fibers washed using Coltide Radiance are smoother and more intact underlining the products shielding properties.

Image 8: SEM images (1000X magnification) of denim jeans washed 10 times with and without Coltide Radiance

Image 8: SEM images (1000X magnification) of denim jeans washed 10 times with and without Coltide RadianceMaintain the Softening Benefits of Your Formulation

The softening benefits of a formulation are not affected by the addition of Coltide Radiance. To evaluate the products effect on the softening properties of a formulation a blind panel test was conducted using towel swatches. No negative effects of softness were identified by 50 trained industrial panelists on samples washed with or without Coltide Radiance (Figure 13). This test was repeated, using a second commercially available fabric conditioner, giving the same results.

Figure 13: Results of blind panel test into softness preference of two terry toweling swatches

Easy Ironing

Coltide Radiance significantly reduces ironing time. To evaluate this easy ironing claim a panel study was conducted, in which panelists ironed four shirts – some washed with detergent and fabric softener treated with Coltide Radiance (0.25g in a 35mL dose of fabric conditioner) and some washed with detergent and using 35mL dose of fabric conditioner. The panelists were recorded ironing the shirts and the contact time between the iron and the fabric was calculated for each shirt ironed.Coltide Radiance reduced the required contact time between the iron and the shirt from 114 seconds to 87 seconds – a 26 second reduction in ironing time for a typical white work shirt. This gives an overall 23% reduction in ironing time and so provides a very strong easier ironing claim.

- Laundry Care

- Performance additive for fabric softeners

- Offers garment protection throughout washing and drying cycle

- Longer lasting colors

- Reduced graying of white fabrics

- Reduced damage and pilling through the wash

- Outstanding results at low inclusion levels

- Works at low wash temperatures

- No impact on softening performance

- Functions

Fiber and Surface Protection

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Use Level

- 1%

- Applications

- Fabric Care

- Fabric capsules (pods)

- Fabric detergents

- Fabric conditioners

- Auxiliary fabric products

- Formulation Guidelines

Coltide Radiance is compatible with all types of commercially used conditioner quat products. Coltide Radiance can be included into either dilute (100ml/wash) or concentrated (25ml28ml/wash) without affecting the stability or performance of the quaternary softener used. Recommended usage levels are very low at 1% in a concentrated formulation. This results in only 0.28g of Coltide Radiance required for a 28ml dosage wash.

When formulating, Coltide Radiance should be added at low mixing speeds after the conditioning quat has been fully mixed into solution, this is advised since in some cases the addition of Coltide Radiance can lower the viscosity of the formulation at this point in the process. It should be added before viscosity adjustment, dye and perfume and can be included during processing at temperatures up to ~60°C. We have found no incompatibility with standard dyes or fragrances when tested with 25 global commercial formulations. Due to the chemistry of Coltide Radiance we would expect that it would be compatible with all currently used fragrances and dyes.

Properties

- Physical Form

- Odor

- Characteristic

- Partially Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point | min. 100 | °C | — |

| pH | 4.5-5.5 | - | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability