Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- CASE Ingredients Functions

- Industrial Additives Functions

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Coating Type

- Applications

- DeCAL 2048 is an ideal dispersing agent for a wide range of water-borne coatings.

- DeCAL 2048 can be used as supplied without pre-dilution.

- DeCAL 2048 can be used to increase the solids loading of the required inorganic dispersion or reduce the working viscosity at a given solids content. As a result, process efficiency is increased and economics improved.

- Textiles: As a polymeric dispersant and protective colloid. Used to aid wash off of reactive dyeings and prints on cellulosic substrate.

- Mining and mineral processing: As an antiscalent in aqueous based mineral processing and the sugar industry, preventing the onset of inorganic precipitation and preventing the fouling of heat exchangers.

- Oilfield uses: As a mineral dispersant for drilling fluids and an anti-scalent for aqueous fluids.

- Application Method

- It is recommended to add the pigment to water containing the dispersing agent with stirring as opposed to addition of the dispersing agent to a pigment slurry. In general, the pH of the final preparation should be in the region of 8.5 to obtain optimum dispersing efficiency.

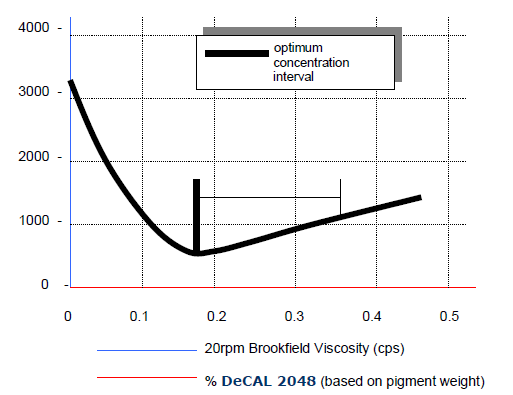

- The optimum amount of dispersing agent required to form a stable dispersion strongly depends on a pigment’s chemical nature, the particle surface and shape. The polymer base of the latex also plays a very important part in the stability equation. In general, significant overdosing may deteriorate the coatings properties (e.g., water resistance) and also generates an economic disadvantage. Likewise insufficient dispersing agent will lead to instability on storage.

- In common with other dispersing agents, because of the batch-to-batch variations of the demands of a specific pigment or latex type it is recommended that the formulator uses 1.5 - 2.0 times the determined optimum level of the dispersing agent.

- DeCAL 2048 has been successfully used to produce a wide range of aqueous slurries and dispersions. Suitable substrates include calcium carbonate, kaolin/china clay, dolomite, ferrite, magnesium hydroxide, mica, satin white, talc, titanium dioxide, zinc oxide etc.

Ex : Rheology curve of a pigment slurry system (containing 65% pigment solids)

Properties

- Physical Form

- Appearance

- Straw colored liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH | 7.5 | — | — |

| Solid Content | 45.0 | % | — |

| Active Content | 40.0 | % | — |

| Viscosity (at 25°C, 20 rpm) | 400.0 | cps | Brookfield |

| Density (at 20°C) | 1.3 | g/cm³ | — |

Technical Details & Test Data

- Stabilty

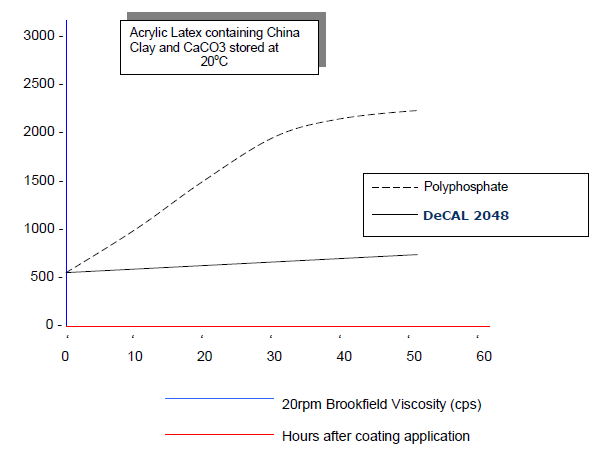

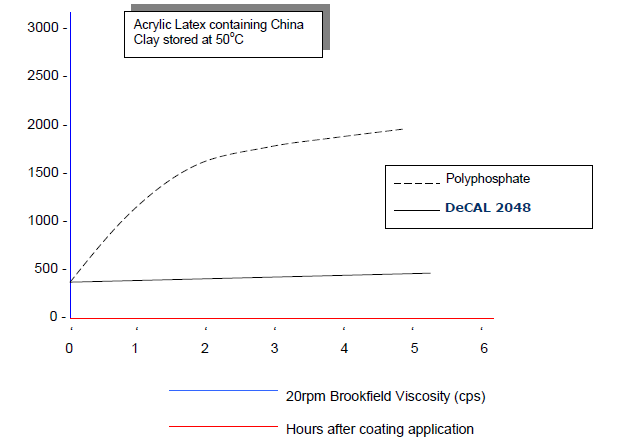

Compared with inorganic dispersing agents, e.g., polyphosphate products, the organic polymer based DeCAL 2048 provides improved storage stability of both the pigment dispersion and the formulated paint. There is little or no adverse reaction to high temperatures or pH changes as indicated in the following graphs, which are examples showing the accelerated effects.

Stability of pigment dispersion to interactions between basic pigment and dispersing agent

Stability of pigment dispersion to heat

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

DeCAL 2048 is supplied in 270 kg nett drums or 1250 kg IBC’s.

Storage & Handling

- Storage Condition

Although DeCAL 2048 is freeze stable, it is recommended to store the product at temperatures above 5°C to enable easy handling of the product.