Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Highlights

- Extended bath life 3-5 times

- Eliminates sludge buildup on heating coils

- Saves energy

- Less iron related challenges

- Does not contain EDTA

- Superior corrosion resistance up to 250 hours salt spray

Meets Mil-P 16232G Type Z.

E-Phos 661 is listed in IMDS.

Equipment Requirements

Type 316 stainless steel is preferred for the processing tank, pumps, piping, nozzles and steam heat exchangers. Gas heated tanks and tubes should be mild steel because stainless steel can crack with direct gas heat.

Applications & Uses

- Markets

- Application Method

Technical Details & Test Data

- Technical Details

Solution Make-up

Concentration: E-Phos 661 liquid concentrate is used at 5% by volume in water.

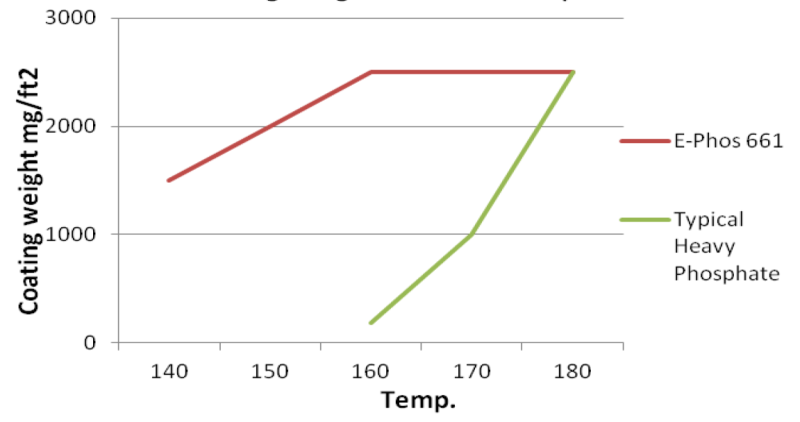

Temperature: Immersion: 140 to 180F

Time: Immersion: 8 to 20 minutes

Coating Weights: Immersion:

Heavy: 2000+ mg/ft2

Medium: 1000 mg/ft2

Light: 500 mg/ft2

Chemical Control: Immersion: 4-6% = 35 - 95 points total acid

Note: When a new solution is made-up, the coating obtained at first will not be as fine grained as those obtained after the solution has been broken in by use.

Finishing Procedure

1. Thoroughly clean and degrease parts with an immersion in a hot EPI alkaline soak cleaner such as E-Kleen SR 102 or E-Kleen SR 108.

2. Bottom-fed, overflowing cold water rinse.

3. Acid pickle 5-15% sulfuric acid 65-90°F, 5-10 minutes.

4. Bottom-fed, overflowing cold water rinse.

5. Bottom-fed, overflowing cold water rinse.

6. Immerse parts in E-Phos 661 solution for length for time required to produce the desired coating weight. Agitation of parts will prevent contact marks.

7. Bottom-fed, overflowing cold water rinse.

8. Bottom-fed, overflowing cold water rinse.

9. Optional E-Tec 555 when optimum corrosion resistance is required (please refer to the E-Tec 555 technical data sheet).

a) Dry parts without further rinsing by using warm moving air or comparable process that prevents staining;

b) Go to Step 10 without any rinsing or drying.

10. Seal finish with an EPI E-Tec protective sealant as recommended by your EPI representative.

a). E-Tec 515 water soluble oil: 5-15% by volume, 120-140°F, 1-3 minutes.

b). E-Tec 503 water displacing oil, 100% by volume, ambient, 1-3 minutes.

c). E-Tec 522 lubricating wax, 50-100% by volume, ambient, 1-3 minutes.

11. Dry off with moving air and/or heat/150-250°F if desired.

Solution Control

Concentration of E-Phos 661 (Total Acid)

1. Take a 10 ml sample of bath, add to 150 ml beaker and dilute with 25 ml of water.

2. Add 5 drops Phenolphthalein Indicator.

3. Titrate with 0.1N NaOH to a pink color end point.

4. The number of ml of 0.1N NaOH is the point count of the Total Acid.

1% = 9 ml

0.11% by volume = 1 ml

Range: 35 to 95 (points)

To raise the concentration by 1.0 point (ml) in the working bath, add 0.11 gals (416 ml) of E-Phos 661 concentrate per 100 gallons of working solution.

Under normal operating conditions, only the total acid should be determined daily for

replenishment and maintenance of the solution.

Free Acid

1. Take a 10 ml sample of the working solution and add to a 150 ml beaker, dilute with 25 ml of water.

2. Add 5-10 drops Bromophenol Blue Indicator.

3. Titrate with 0.1N NaOH to a reddish-purple color. The number of ml of 0.1N NaOH is the point count of the Free Acid.

The working solution is maintained and operated on a Ratio: Total Acid ÷ Free Acid

The operating range of this RATIO is 4.5 for a new bath to 9.0 for older baths with high iron.

To lower the free acid, small additions of Soda Ash (Sodium Carbonate) should be used. The

free acid measures the aggressiveness of the bath. The RATIO indicates the chemical balance of ingredients.

Iron Determination

1. Take a 10 ml sample of the working solution, dilute with water to 25 ml and add 2 ml of concentrated sulfuric acid.

2. Titrate with 0.2N Potassium Permanganate until the solution turns purple.

3. The number of ml of 0.2N Potassium Permanganate equals the points of iron.

If the iron concentration goes over 13 grams per liter it is recommended that some of the solution be removed from the tank and the volume be brought back to operating level with water. E-Phos 661 concentrate is then added to adjust the solution to its optimum operating range.

Solution Maintenance

As the bath is used, an insoluble by-product is formed which settles to the bottom of the tank which should be periodically removed. Allow sludge to settle, decant off and save the clean solution, remove sludge, return solution to tank and replenish to operating conditions.

Heating coils will become scaled and should be cleaned when the scale reduces heating efficiency.

At a minimum, a tank should contain one gallon of working solution per square foot of work processed at one time. It is preferable to have two gallons of solution per square foot of work.- Technical Details

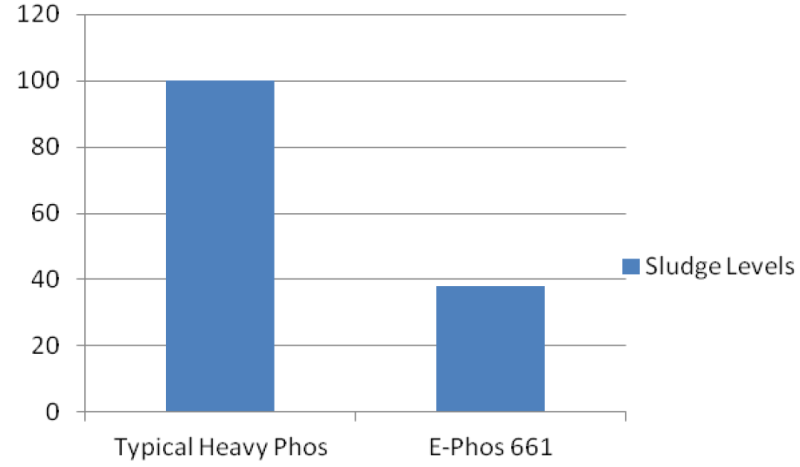

E-Phos 661 Significantly Reduces Sludge

Based on Equivalent Works load

Coating Weight at Various Temperatures

Safety & Health

- Caution

The E-Phos 661 concentrate and its working solutions are acidic. Avoid contact with eyes, skin and clothing. Wear eye protection (glasses, goggles and face shield), protective rubber gloves and rubber apron when mixing solutions and while working with solutions. Avoid contact of the E-Phos 661 with alkaline materials. Do not mix E-Phos 661 with any other chemicals or solutions.

Packaging & Availability

- Packaging

67 pound net (5 gallons) or 734 pound net (55 gallons) non-returnable containers.