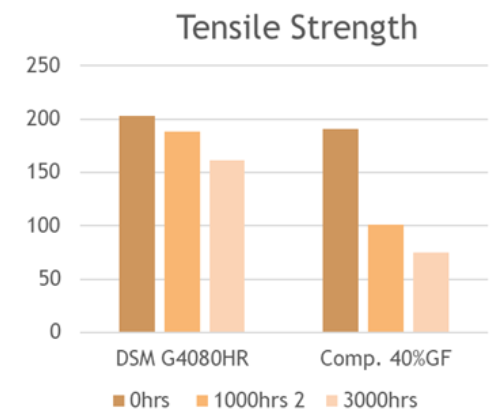

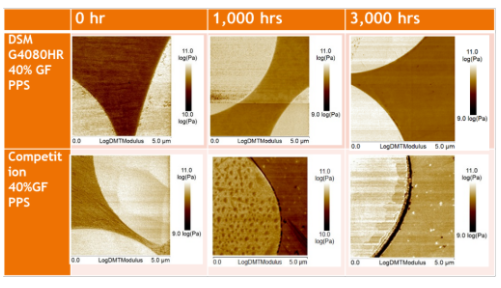

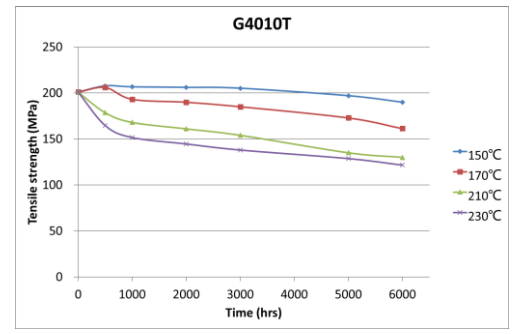

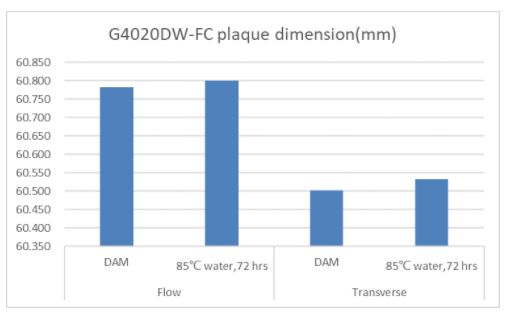

Xytron PPS is a high-performance plastics compound based on linear polyphenylene sulfide that contributes to three key strengths: heat aging performance up to 240 °C; chemical resistance at high temperature; and dimensional stability.

This polyphenylene sulfide (PPS) offers excellent chemical resistance, dimensional stability and is intrinsically flame retardant because of its electrical properties.

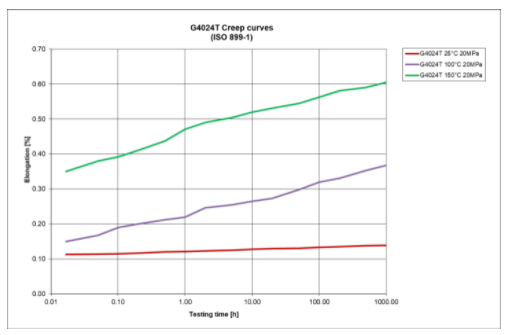

Xytron PPS offers high stiffness up to a glass transition temperature of 90°C, with a continuous use temperature between 240-260°C.

This family of PPS grades is well suited for a broad range of automotive, electronics and electrical, water management and specialized industrial applications.