Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- ADAS Radar Housing Application Data

Details

Envalior offers many solutions for today’s complex ADAS components, including proven material solutions such as Arnite® PBT. New Xytron™ PPS material solutions are also being developed to deliver more affordable performance compared to polyetherimide (PEI) thermoplastics.Benefits

- High design flexibility for molding thin-walled parts

- High continuous use temperatures (CUT) for superior thermal load management

- Excellent processing capabilities supporting easy injection molding

- High hydrolytic and chemical resistance to extend part lifetimes

- Cost-effective low Dk and Dk radome solutions

- Medium conductivity grades minimizing reflections in midframes

- High electric and thermal conductivity grades for back covers

- Laser-welding options for rapidly bonding radomes and back covers

Properties

- Flame Rating

- Mechanical Properties

- Thermal Properties

- Electrical Properties

- Other Properties

- Rheological Properties

- Grade Coding for Injection Molding

Xytron™ PPS reinforced injection molding grades.

| Value | Units | Test Method / Conditions | |

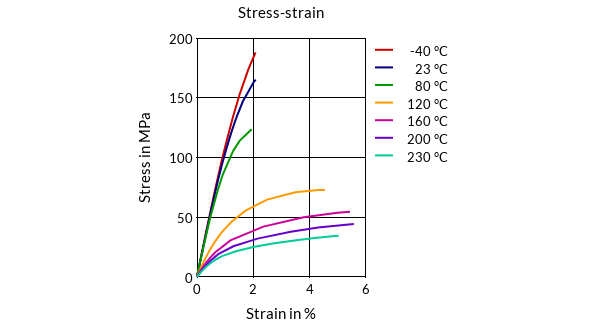

| Tensile Modulus | 12000 | MPa | ISO 527-1/-2 |

| Tensile Modulus (-40°C) | 12000 | MPa | ISO 527-1/-2 |

| Tensile Modulus (120°C) | 4700 | MPa | ISO 527-1/-2 |

| Tensile Modulus (160°C) | 3500 | MPa | ISO 527-1/-2 |

| Tensile Modulus (200°C) | 2950 | MPa | ISO 527-1/-2 |

| Stress at Break | 170 | MPa | ISO 527-1/-2 |

| Stress at Break (-40°C) | 185 | MPa | ISO 527-1/-2 |

| Stress at Break (120°C) | 70 | MPa | ISO 527-1/-2 |

| Stress at Break (160°C) | 55 | MPa | ISO 527-1/-2 |

| Stress at Break (200°C) | 45 | MPa | ISO 527-1/-2 |

| Strain at Break | 2 | % | ISO 527-1/-2 |

| Strain at Break (at -40°C) | 2 | % | ISO 527-1/-2 |

| Strain at Break (at 120°C) | 4.6 | % | ISO 527-1/-2 |

| Strain at Break (at 160°C) | 5.3 | % | ISO 527-1/-2 |

| Strain at Break (at 200°C) | 5.4 | % | ISO 527-1/-2 |

| Flexural Modulus | 10000 | MPa | ISO 178 |

| Flexural Modulus (at 120°C) | 4500 | MPa | ISO 178 |

| Flexural Modulus (at 160°C) | 3300 | MPa | ISO 178 |

| Flexural Modulus (at 200°C) | 2900 | MPa | ISO 178 |

| Flexural Strength | 240 | MPa | ISO 178 |

| Flexural Strength (at 120°C) | 96 | MPa | ISO 178 |

| Flexural Strength (at 160°C) | 68 | MPa | ISO 178 |

| Flexural Strength (at 200°C) | 56 | MPa | ISO 178 |

| Charpy Impact Strength (at +23°C) | 58 | kJ/m² | ISO 179/1eU |

| Charpy Impact Strength (at -30°C) | 56 | kJ/m² | ISO 179/1eU |

| Charpy Notched Impact Strength (at +23°C) | 9 | kJ/m² | ISO 179/1eA |

| Charpy Notched Impact Strength (at -30°C) | 8 | kJ/m² | ISO 179/1eA |

| Weldline Strength (at thickness 4 mm) | 75 | MPa | ISO 527-1/-2 |

| Weldline Strain (at thickness 4 mm) | 0.85 | % | ISO 527-1/-2 |

| Rockwell Hardness (R scale) | 120 | — | ISO 2039-2 |

| Rockwell Hardness (M scale) | 100 | — | ISO 2039-2 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature (10°C/min) | 280 | °C | ISO 11357-1/-3 |

| Glass Transition Temperature (at 10°C/min) | 90 | °C | ISO 11357-1/-2 |

| Temperature of Deflection Under Load (1.80 MPa) | 265 | °C | ISO 75-1/-2 |

| Temperature of Deflection Under Load (0.45 MPa) | 280 | °C | ISO 75-1/-2 |

| Temperature of Deflection Under Load (8.00 MPa) | 185 | °C | ISO 75-1/-2 |

| Coefficient of Linear Thermal Expansion (parallel) | 0.18 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal) | 0.5 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (parallel, above Tg) | 0.18 | E-4/°C | ISO 11359-1/-2 |

| Coefficient of Linear Thermal Expansion (normal, above Tg) | 1.2 | E-4/°C | ISO 11359-1/-2 |

| Burning Behaviour (at 3.0 mm Nominal Thickness) | UL V-0 | class | IEC 60695-11-10 |

| Relative Temperature Index (Electrical, 0.4 mm) | 130 | °C | UL746B |

| Relative Temperature Index (Electrical, 3 mm) | 130 | °C | UL746B |

| Relative Temperature Index (with impact, 0.4 mm) | 130 | °C | UL746B |

| Relative Temperature Index (with impact, 3 mm) | 130 | °C | UL746B |

| Relative Temperature Index (without impact, 0.4 mm) | 130 | °C | UL746B |

| Relative Temperature Index (without impact, 3 mm) | 130 | °C | UL746B |

| Value | Units | Test Method / Conditions | |

| Relative Permittivity (1GHz) | 3.8 | — | IEC 60250 |

| Relative Permittivity (5GHz) | 3.8 | — | IEC 60250 |

| Dissipation Factor (1GHz) | 30 | E-4 | IEC 60250 |

| Dissipation Factor (5GHz) | 45 | E-4 | IEC 60250 |

| Volume Resistivity | >1E13 | Ohm*m | IEC 62631-3-1 |

| Surface Resistivity | >1E15 | Ohm | IEC 62631-3-2 |

| Electric Strength | 34 | kV/mm | IEC 60243-1 |

| Comparative Tracking Index | 175 | V | IEC 60112 |

| Value | Units | Test Method / Conditions | |

| Water Absorption in Water (at 23°C after 24h) | 0.05 | % | ISO 62 |

| Humidity Absorption | 0.05 | % | Sim. to ISO 62 |

| Density | 1550 | kg/m³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Molding Shrinkage (parallel) | 0.21 | % | ISO 294-4 |

| Molding Shrinkage (normal) | 0.65 | % | ISO 294-4 |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Chemical Resistance

Chemical Type Chemical Name Resistance Other 1% nonylphenoxy-polyethyleneoxy ethanol in water at 23°C resistant Other 50% Oleic acid + 50% Olive Oil at 23°C resistant Other Acetaldehyde (40% by mass) at 23°C resistant Other Acetamide (50% by mass) at 23°C resistant Other Acetamide (50% by mass) at >140°C resistant Other Acetic acid (10% by mass) at 100°C resistant Other Acetic acid (10% by mass) at 23°C resistant Acids Acetic Acid (5% by mass) at 23°C resistant Other Acetic acid (95% by mass) at 23°C resistant Ketones Acetone at 23°C resistant Other Acetophenone at 23°C resistant Other Acetyl chloride at 23°C resistant Other Acetylene at 23°C resistant Other Acrylic acid at 23°C resistant Other Acrylonitril at 23°C resistant Other Aliphatic amines at 23°C resistant Other Aliphatic hydrocarbons at 23°C resistant Other Alkylbenzenes at 23°C resistant Other Allyl alcohol at 23°C resistant Other Aluminum acetate (saturated) at 23°C resistant Other Aluminum chloride (10% by mass) at 23°C resistant Other Aluminum hydroxide (saturated) at 23°C resistant Other Aluminum salts of mineral acids (saturated) at 23°C resistant Other Aluminum trichloride (10% by mass) at 23°C resistant Other Amino acids (saturated) at 23°C resistant Other Ammonia at 23°C resistant Other Ammonium chloride (35% by mass) at 100°C resistant Other Ammonium chloride (35% by mass) at 23°C resistant Other Ammonium fluoride (saturated) at 23°C resistant Other Ammonium hydroxide (10% by mass) at 23°C resistant Bases Ammonium Hydroxide solution (10% by mass) at 23°C resistant Other Ammonium salts of mineral acids (10% by mass) at 23°C resistant Other Ammonium salts of mineral acids (10% by mass) at 50°C resistant Other Ammonium sulfide (saturated) at 23°C resistant Other Ammonium thiocyanate (saturated) at 23°C resistant Other Amyl acetate at 100°C resistant Other Amyl acetate at 23°C resistant Other Amyl alcohol at 23°C resistant Other Aniline at 23°C resistant Other Anise at 23°C resistant Other Anodizing liquid (HNO3/H2SO4) at 23°C resistant Other Antimony trichoride (saturated) at 23°C resistant Other Aqua Regia (HCl/HNO3) at 23°C resistant Other Aromatic hydrocarbons at 23°C resistant Other ASTM 1 at 23°C resistant Other ASTM 3 at 23°C resistant Mineral oils Automatic hypoid-gear oil Shell Donax TX at 135°C resistant Other Bariumsalts of mineral acids at 23°C resistant Other Benzaldehyde at 23°C resistant Other Benzene at 23°C resistant Other Benzene at 80°C resistant Other Benzoic acid (20% by mass) at 23°C resistant Other Benzoic acid (saturated) at 23°C resistant Other Benzyl alcohol at 23°C resistant Other Beverages at 23°C resistant Other Bleaching agent (NaOCl) at 23°C resistant Other Blood at 23°C resistant Other Boric acid (10% by mass) at 23°C resistant Other Boron trifluoride at 23°C resistant Other Brake fluids (DOT 3/4) at 23°C resistant Other Bromine water (saturated) at 23°C resistant Other Bromobenzene at 23°C resistant Other Bromochlorodifluoromethane at 23°C resistant Other Bromotrifluoromethane at 23°C resistant Other Burnishing oil at 23°C resistant Other Butadiene at 23°C resistant Other Butane at 23°C resistant Other Butanediols at 23°C resistant Other Butanediols at >140°C resistant Other Butanols at 23°C resistant Other Butene glycol at 23°C resistant Other Butene glycol at >160°C resistant Other Butene-1 at 23°C resistant Other Butter at 23°C resistant Other Butyl acetate at 23°C resistant Other Butyl acrylate at 23°C resistant Other Butyl glycolate at 23°C resistant Other Butyl phthalate at 23°C resistant Other Butyric acid (20% by mass) at 23°C resistant Other Butyrolactone at 23°C resistant Other Butyrolactone at >90°C resistant Other Calcium chloride (10% by mass) at 100°C resistant Other Calcium chloride (10% by mass) at 23°C resistant Other Calcium chloride (alcoholic) (20% by mass) at 23°C resistant Other Calcium chloride (saturated) at 100°C resistant Other Calcium chloride (saturated) at 23°C resistant Other Calcium chloride (saturated) at 60°C resistant Other Calcium hydroxide (saturated) at 23°C resistant Other Calcium hypochloride (saturated) at 23°C resistant Other Camphor (alcoholic) (50% by mass) at 23°C resistant Other Caprolactam (50% by mass) at 23°C resistant Other Caprolactam (50% by mass) at >150°C resistant Other Carbon dioxide (moist) at 23°C resistant Other Carbon disulfide at 23°C resistant Other Carbon disulfide at 60°C resistant Other Carbon tetrachloride at 23°C resistant Other Casein at 23°C resistant Other Castor oil at 23°C resistant Other Chloral hydrate at 23°C resistant Other Chloramines (10% by mass) at 23°C resistant Other Chlorinated biphenyls at 80°C resistant Other Chlorine gas (dry) at 23°C resistant Other Chlorine gas (moist) at 23°C resistant Other Chlorine water at 23°C resistant Other Chloroacetic acid (10% by mass) at 23°C resistant Other Chlorobenzene at 23°C resistant Other Chlorobenzene at 50°C resistant Other Chlorobromomethane at 23°C resistant Other Chlorodifluoroethane at 23°C resistant Other Chlorodifluoromethane at 23°C resistant Other Chlorofluoroethylene at 23°C resistant Other Chloroform at 23°C resistant Other Chlorosulfonic acid (10% by mass) at 23°C resistant Other Chromic acid (1% by mass) at 23°C resistant Other Chromic acid (10% by mass) at 23°C resistant Acids Chromic Acid solution (40% by mass) at 23°C resistant Other Chromyl chloride at 23°C resistant Other Cinnamon at 23°C resistant Other cis-2-butene at 23°C resistant Other Citric acid (10% by mass) at 23°C resistant Other Citric acid (20% by mass) at 80°C resistant Acids Citric Acid solution (10% by mass) at 23°C resistant Other Cobalt salt (20% by mass) at 23°C resistant Other Coolant Glysantin G48, 1:1 in water at 125°C resistant Other Copper sulfate (10% by mass) at 23°C resistant Other Copper(II) salt (10% by mass) at 23°C resistant Other Cresols at 23°C resistant Other Cycloalcohols (incl their esters) at 23°C resistant Other Cycloalkanes at 23°C resistant Other Cycloalkanones at 23°C resistant Other Cyclohexanol at 23°C resistant Other Decalin at 23°C resistant Other Deionized water at 90°C resistant Other Developer (photografic) at 23°C resistant Other Diamyl phthalate at 23°C resistant Other Dibutyl phthalate at 23°C resistant Other Dibutyl phthalate at 60°C resistant Other Dichlorobenzene at 23°C resistant Other Dichloroethane at 23°C resistant Other Dichloroethylene at 23°C resistant Other Dichlorofluoromethane at 23°C resistant Other Dichlorotetrafluoroethane at 23°C resistant Standard Fuels Diesel EN 590 at 100°C limited resistant, tests necessary to verify Standard Fuels Diesel fuel (pref. ISO 1817 Liquid F) at 23°C resistant Standard Fuels Diesel fuel (pref. ISO 1817 Liquid F) at 90°C resistant Standard Fuels Diesel fuel (pref. ISO 1817 Liquid F) at >90°C limited resistant, tests necessary to verify Ethers Diethyl ether at 23°C resistant Other Diethylene glycol at 23°C resistant Other Diethylene glycol at >140°C resistant Other Difluoromethane at 23°C resistant Other Dimethyl acetamide at 23°C resistant Other Dimethyl acetamide at >150°C resistant Other Dimethyl ether at 23°C resistant Other Dimethylamine at 23°C resistant Other Dimethylformamide at 23°C resistant Other Dimethylformamide at 90°C resistant Other Dimethylsilane at 23°C resistant Other Dimethylsulfoxide at 125°C resistant Other Dimethylsulfoxide at 23°C resistant Other Dinonyl phtalate at 23°C resistant Other Dioctyl phtalate at 23°C resistant Other Dioxan at 23°C resistant Other Dioxan at 60°C resistant Other Diphenyl ether at 80°C resistant Other Dipropyl ether at 23°C resistant Other DOT No. 4 Brake fluid at 120°C resistant Other DOT No. 4 Brake fluid at 130°C resistant Other Drilling oil at 23°C resistant Other Duck grease at 23°C resistant Other Edible fats waxes and oils at 100°C resistant Other Electroplating bath (acidic) at 23°C resistant Other Electroplating bath (alkali) at 23°C resistant Other Essential oil at 23°C resistant Other Ethane at 23°C resistant Alcohols Ethanol at 23°C resistant Other Ethyl Acetate at 23°C resistant Other Ethyl amine at 23°C resistant Other Ethyl bromide at 23°C resistant Other Ethyl chloride at 23°C resistant Other Ethylene at 23°C resistant Other Ethylene carbonate at 100°C resistant Other Ethylene carbonate at 50°C resistant Other Ethylene chloride at 23°C resistant Other Ethylene chlorohydrin at 23°C resistant Other Ethylene Glycol (50% by mass) in water at 108°C resistant Other Ethylene glycol at 100°C resistant Other Ethylene glycol at 23°C resistant Other Ethylene oxide at 23°C resistant Other Ethylene oxide at >80°C resistant Other Ethylenediamine at 23°C resistant Other Fatty acids at 23°C resistant Other Fatty alcohols at 23°C resistant Other Ferric chloride (2,5% by mass) at 100°C resistant Other Ferric chloride (2,5% by mass) at 23°C resistant Other Fish oil at 23°C resistant Other Fixer (photografic) at 23°C resistant Other Fluorinated hydrocarbons at 70°C resistant Other Fluorine at 23°C resistant Other Formaldehyde (30% by mass) at 23°C resistant Other Formamide at 23°C resistant Other Formamide at >150°C resistant Other Formic acid (10% by mass) at 23°C resistant Other Formic acid (10% by mass) at 50°C resistant Other Formic acid (30% by mass) at 23°C resistant Other Fruit juices at 23°C resistant Other Fuel; Diesel at 85°C resistant Other Fuel; FAM 1A at 23°C resistant Other Fuel; FAM 2A at 23°C resistant Other Fuel; Gasoline at 85°C resistant Other Fuel; LPG at 23°C resistant Other Furfural at 23°C resistant Other Furfuryl alcohol at 23°C resistant Other Glucose at 23°C resistant Other Glycerol at 170°C resistant Other Glycerol at 23°C resistant Other Glycolic acid (30% by mass) at 23°C resistant Other Glycols at 23°C resistant Other Grease (based on ester oils) at <100°C resistant Other Grease (based on metal soaps) at <100°C resistant Other Grease (based on polyphenylester) at <100°C resistant Other Hardening oils at 23°C resistant Other Heating oils at 23°C resistant Other Heptane at 23°C resistant Other Hexachlorobenzene at 80°C resistant Other Hexachloroethane at 23°C resistant Other Hexafluoroisopropanol at 23°C resistant Other Hexamethylenetetramine at 23°C resistant Other Hexane at 23°C resistant Other Hydraulic fluids at 100°C resistant Mineral oils Hydraulic oil Pentosin CHF 202 at 125°C resistant Other Hydrobromic acid (10% by mass) at 23°C resistant Other Hydrochloric acid (10% by mass) at 23°C resistant Other Hydrochloric acid (20% by mass) at 23°C resistant Acids Hydrochloric Acid (36% by mass) at 23°C resistant Other Hydrochloric acid (conc.% by mass) at 23°C resistant Other Hydrofluoric acid (40% by mass) at 23°C not resistant Other Hydrofluoric acid (5% by mass) at 23°C resistant Other Hydrogen at 23°C resistant Other Hydrogen peroxide (0.5% by mass) at 23°C resistant Other Hydrogen peroxide (1% by mass) at 23°C resistant Other Hydrogen peroxide (3% by mass) at 23°C resistant Other Hydrogen peroxide (30% by mass) at 23°C resistant Other Hydrogen peroxide at 23°C resistant Other Hydrogen sulfide (10% by mass) at 23°C resistant Other Hydroiodic acid at 23°C resistant Other Hydroquinone (5% by mass) at 23°C resistant Other Impregnating oils at 23°C resistant Other Ink at 23°C resistant Mineral oils Insulating Oil at 23°C resistant Other Iodine (alcoholic) at 23°C resistant Other Iron(III)chloride (acidic) (10% by mass) at 23°C resistant Other Iron(III)chloride (neutral) (10% by mass) at 23°C resistant Other Iron(III)chloride (saturated) at 23°C resistant Other Iron(III)thiocyanate (10% by mass) at 23°C resistant Standard Fuels ISO 1817 Liquid 1 at 60°C resistant Standard Fuels ISO 1817 Liquid 2 at 60°C resistant Standard Fuels ISO 1817 Liquid 3 at 60°C resistant Standard Fuels ISO 1817 Liquid 4 at 60°C resistant Hydrocarbons iso-Octane at 23°C resistant Other isoamylalcohol at 23°C resistant Other Isocyanates (aromatic) at 23°C resistant Other Isooctane at 80°C resistant Other Isopropanol at 23°C resistant Other Isopropanol at 60°C resistant Alcohols Isopropyl alcohol at 23°C resistant Other Ketones (aliphatic) at 23°C resistant Acids Lactic Acid (10% by mass) at 23°C resistant Other Lactic acid at 10°C resistant Other Lactic acid at 90°C resistant Other Lead acetate (10% by mass) at 23°C resistant Other Linseed oil at 23°C resistant Other Lithium bromide (10% by mass) at 23°C resistant Other Lithium chloride (20% by mass) at 23°C resistant Other Lithium hydroxide (10% by mass) at 23°C resistant Other Lithium hydroxide (10% by mass) at 80°C resistant Other Lubricating oil (gear) at <130°C resistant Other Lubricating oil (hydraulics) at <130°C resistant Other Lubricating oil (transformers) at <130°C resistant Other Magnesium hydroxide (10% by mass) at 23°C resistant Other Magnesium salts (10% by mass) at 23°C resistant Other Maleic acid (25% by mass) at 23°C resistant Other Maleic acid (saturated) at 23°C resistant Other Manganese salts (10% by mass) at 23°C resistant Other Mercury at 23°C resistant Other Mercury(II)chloride (saturated) at 23°C resistant Other Methane at 23°C resistant Alcohols Methanol at 23°C resistant Other Methyl acetate at 23°C resistant Other Methyl chloride at 23°C resistant Other Methyl ethyl ketone at 23°C resistant Other Methyl formate at 23°C resistant Other Methyl glycol at 23°C resistant Other Methylamine at 23°C resistant Other Methylaniline at 23°C resistant Other Methylbromide at 23°C resistant Other Methylene chloride at 23°C resistant Other Methylpyrrolidone at 23°C resistant Other Milk at 23°C resistant Mineral oils Motor oil OS206 304 Ref.Eng.Oil, ISP at 135°C resistant Other n-Butyl ether at 23°C resistant Other n-Butyl glycol at 23°C resistant Hydrocarbons n-Hexane at 23°C resistant Other Naphtha at 23°C resistant Other Naphthalene at 23°C resistant Other Naphthalenesulfonic acids at 23°C resistant Other Naphthenic acids at 23°C resistant Other Naphthols at 23°C resistant Other Nickel nitrate (10% by mass) at 23°C resistant Other Nickel salts (10% by mass) at 23°C resistant Other Nitric acid (10% by mass) at 23°C resistant Other Nitric acid (2% by mass) at 23°C resistant Other Nitric acid (20% by mass) at 23°C resistant Acids Nitric Acid (40% by mass) at 23°C resistant Other Nitric acid (conc.% by mass) at 23°C resistant Other Nitrobenzene at 23°C resistant Other Nitrobenzene at >100°C resistant Other Nitrocellulose lacquers (alcoholic) at 23°C resistant Other Nitrocellulose lacquers (non-alcoholic) at 23°C resistant Other Nitrogen oxides at 23°C resistant Other Nitromethane at 23°C resistant Other Nitropropane at 23°C resistant Other Nitrotoluene at 23°C resistant Other Nitrotoluene at >100°C resistant Other Nitrous fumes at 23°C resistant Other Nitrous oxide at 23°C resistant Other Octane at 23°C resistant Other Octene at 23°C resistant Other Oil (Burmah TAF 21) at 23°C resistant Other Oil (Castrol TAF) at 23°C resistant Other Oil (Shell 10W40) at 23°C resistant Other Oil (Shell Dexron ATF) at 23°C resistant Other Oil (Shell Spirax EP90) at 23°C resistant Other Oil (transformers, switchgear) at 50°C resistant Other Oils (vegatable, mineral, ethereal) at 23°C resistant Other Oleic acid at 23°C resistant Other Oleum (H2SO4+SO3) at 23°C resistant Other Oxalic acid (10% by mass) at 23°C resistant Other Oxalic acid (10% by mass) at 80°C resistant Other Ozone at 23°C resistant Other Paint solvents at 23°C resistant Other Palmatic acid at 80°C resistant Other Paraffin at 23°C resistant Other Pentane at 23°C resistant Other Pentasin CHF 11 (S) at 23°C resistant Other Pentasin CHF 7.1 at 23°C resistant Other Peracetic acid at 23°C resistant Other Perchloric acid (10% by mass) at 23°C resistant Other Perchloric acid (conc.% by mass) at 23°C resistant Other Perchloro ethylene at 23°C resistant Other Petroleum at 23°C resistant Other Petroleum ether and solvents at 80°C resistant Other Phenol (alc. sol.) (70% by mass) at 23°C resistant Other Phenol (conc.% by mass) at 23°C resistant Other Phenol at >40°C resistant Other Phenol solution (5% by mass) at 23°C resistant Other Phenyl ether at 23°C resistant Other Phenyl ethyl alcohol at 23°C resistant Other Phenyl ethyl alcohol at >160°C not resistant Other Phosphate sol. (neutral, alkaline) (10% by mass) at 23°C resistant Other Phosphine at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C resistant Other Phosphoric acid (3% by mass) at 23°C resistant Other Phosphoric acid (conc.% by mass) at 23°C resistant Other Phosphorous acid (conc.% by mass) at 23°C resistant Other Phosphorous oxychloride at 23°C resistant Other Phosphorous trichloride at 23°C resistant Other Phthalic acid (saturated) at 23°C resistant Other Polyols at 23°C resistant Other Potassium bromide (10% by mass) at 23°C resistant Other Potassium bromide (saturated) at 23°C resistant Other Potassium carbonate (saturated) at 23°C resistant Other Potassium chloride (10% by mass) at 23°C resistant Other Potassium chloride (10% by mass) at 70°C resistant Other Potassium chloride (saturated) at 23°C resistant Other Potassium cyanide at 23°C resistant Other Potassium dichromate (5% by mass) at 23°C resistant Other Potassium dichromate (saturated) at 23°C resistant Other Potassium hydroxide (50% by mass) at 23°C resistant Other Potassium nitrate (10% by mass) at 23°C resistant Other Potassium perchlorate (10% by mass) at 23°C resistant Other Potassium permanganate (1% by mass) at 23°C resistant Other Potassium permanganate (10% by mass) at 23°C resistant Other Potassium persulphate (10% by mass) at 23°C resistant Other Potassium rhodanide (saturated) at 23°C resistant Other Potassium thiocyanate (saturated) at 23°C resistant Other Propane at 23°C resistant Other Propanol at 23°C resistant Other Propanol at >100°C resistant Other Propene at 23°C resistant Other Propionic acid (20% by mass) at 23°C resistant Other Propionic acid (5% by mass) at 23°C resistant Other Propionic acid (50% by mass) at 23°C resistant Other Pyridine at 23°C resistant Other Pyridine at 80°C resistant Other Pyrocatechol at 23°C resistant Other Pyrrolidone at 23°C resistant Other Pyruvic acid (10% by mass) at 23°C resistant Other Rainwater (acidic) at 23°C resistant Other Rapeseed oil at 23°C resistant Other Refrigerator oil at 23°C resistant Other Resorcinol (alcoholic) (1% by mass) at 23°C resistant Other Resorcinol (alcoholic) (50% by mass) at 23°C resistant Other Road salts at 23°C resistant Mineral oils SAE 10W40 multigrade motor oil at 130°C resistant Mineral oils SAE 10W40 multigrade motor oil at 23°C resistant Other SAE 80 at 23°C resistant Mineral oils SAE 80/90 hypoid-gear oil at 130°C resistant Other Salicylic acid (saturated) at 23°C resistant Other Seawater at 23°C resistant Other Sewing machine oil at 23°C resistant Other Silane at 23°C resistant Other Silicone oils at <80°C resistant Other Silicone oils at >100°C resistant Other Silver nitrate (10% by mass) at 23°C resistant Other Soap solution (10% by mass) at 80°C resistant Other Sodium - Machinery for Injection Molding

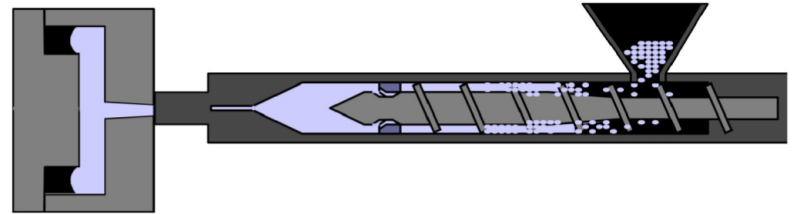

Xytron™ grades can be processed on general injection molding machines.

Screw Geometry- Typically 3-zone screw designs with volumetric compression ratios of approximately 2.5 work fine.

Steel Type

- Abrasive-resistant steel types which are generally used for glass fiber reinforced, high temperature, polyamide or PPS materials are also to be used for the Xytron™ grades in tools, nozzles and screws. Failing to do so may result in wear, especially of the screw/barrel (due to the high temperatures involved there), which can lead to decreasing processing performance.

Nozzle Temperature Control

- The use of an open nozzle with good temperature control and an independently-controlled thermocouple nearby the tip and heater bands with sufficient output is recommended.

Hot Runner Layout

- Try to achieve a close contact with your hot runner supplier and Envalior as the material supplier, to be sure that the right hot runner system is chosen.

- When processing Xytron™ with hot runners, keep in mind these basic rules:

- Central bushing heated separately

- Only use external heated system

- Manifold heated from both sides

- Tip with thermocouple in front (near gate)

- Very accurate temperature control in the gate area

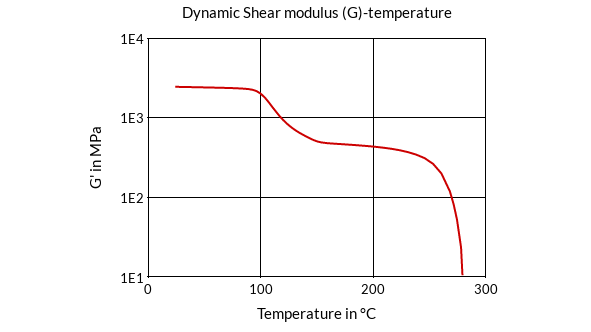

- Dynamic Shear Modulus (G)-Temperature

- Temperature Settings for Injection Molding

Mold Temperature

- Xytron™ can be used with a wide range of tool temperatures (140 - 150°C / 284 - 302°F). However, we recommend a low mold temperature for parts with thick walls and a high mold temperature for good dimensional stability, flow properties and surface esthetics.

Barrel Temperature

- Optimal settings are governed by barrel size and residence time. Furthermore, the level of glass and/or mineral reinforcement has to be taken into account.

Mold/Tool Measured melt Nozzle Front Center Rear 140 - 150°C

284 - 302°F310-340°C

590-644°F310-340°C

590-644°F320-340°C

608-644°F310-330°C

590-626°F300-320°C

572-608°FMelt Temperature

- To generate a good and homogeneous melt, the melt temperature should always be above 310°C / 590°F. Optimal mechanical properties will be achieved at melt temperatures between 310-340°C / 590-644°F.

- We advise to frequently measure the melt temperature by pouring the melt in a Teflon cup and inserting a thermo probe into the melt.

Hot Runner Temperature

- A hot runner temperature set to the same level as the nozzle temperature should work fine and not lead to excessive overheat of the Xytron™ grade. When starting up, an increased tip temperature may be necessary to overcome a frozen nozzle.

- Stress-Strain

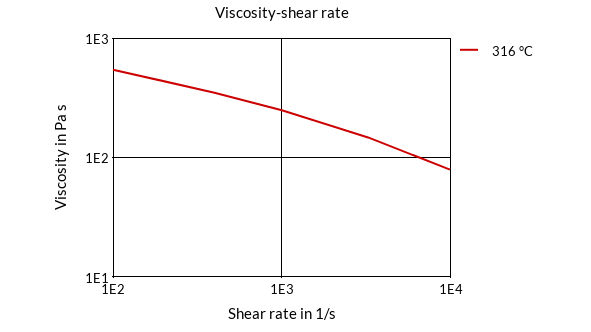

- Viscosity-Shear Rate

- General Processing Settings for Injection Molding

Screw Rotation Speed

- To realize a good and homogeneous melt, it is advised to set a screw rotation speed resulting in a plasticizing time that is just within the cooling time.

- The rotational speed of the screw should not exceed 6500 / D RPM (where D is the screw diameter in mm).

Back Pressure

- Back pressure should be between 30-100 bars effective. Keep it low in order to prevent nozzle-drooling, excessive shear heating and long plasticizing times.

Decompression

- In order to prevent nozzle drool after plasticizing and retracting the nozzle from the mold, a short decompression stroke can be used. However, to prevent oxidation of the melt, which may result in surface defects on the parts, it is recommended to keep this as short as possible.

Injection Speed

- Moderate to high injection speeds are required in order to prevent premature crystallization in the mold during injection phase and to obtain a better surface finish. The recommended injection speed profile goes from fast (for sprue and runner filling) to medium (for part filling) to avoid excessive shear heating and allow air to escape from the mold. Adequate mold venting is required to avoid burning at the end of the flow path (due to diesel effect).

Injection Pressure

- The real injection pressure is the result of the flowability of the material (crystallization rate, flow length, wall thickness, filling speed). The set injection pressure should be high enough to maintain the set injection speed (use set injection pressure higher than the peak pressure if possible). Tooling air vents must be effective to allow optimum filling pressure and prevent burn marks.

Holding Time

- Effective holding time is determined by part thickness and gate size. Holding time should be maintained until a constant product weight is achieved.

Holding Pressure

- The most adequate holding pressure is the level whereby no sinkmarks or flash are visible. A too high holding pressure can lead to stresses in the part.

Cooling Time

- Actual cooling time will depend on part geometry and dimensional quality requirements as well as the tool design (gate size).

- Melt Residence Time for Injection Molding

The optimal Melt Residence Time (MRT) for Xytron™ G3080R is ≤ 6 minutes with preferably at least 50% of the maximal shot volume used. The MRT should not exceed 8 minutes.

A formula to estimate the MRT is described below:

𝑀𝑅𝑇 = (∏D³ρ/m) * (t/60)

Whereas:

MRT = Melt Residence Time [minutes]

D = Screw Diameter [cm]

p = Melt Density [g/cm3]

m = Shot Weight [g]

t = Cycle Time [s]

Please note: In the calculation above, the hotrunner volume has not been taken into account. When a hotrunner is part of the setup, please add the hotrunner volume to the calculation.- Startup/Shut Down/Cleaning for Injection Molding

- Production has to be started and stopped with a clean machine. Cleaning can be done with PA6-GF or PA66-GF, applicable cleaning agents or HDPE. Hot runners can also be cleaned and put out of production cleaning them with PA6-GF or PA66-GF.

- Production Breaks for Injection Molding

- During production breaks longer than a few minutes, we advise emptying the barrel. The temperature of the barrel and the hot runner [if applicable) should be reduced to a level far enough below the melting point of the compound in order to stop decomposition of the compound.

- When the hot runner, nozzle, or even the screw is blocked, be aware that under these conditions a sudden outburst of molten material can take place. Always wear personal safety protections for hand/eye/body.

Packaging & Availability

- Packaging Type

Storage & Handling

- Material Handling for Injection Molding

Storage

- In order to prevent contamination, supplied packaging should be kept closed and undamaged. For the same reason, partial bags should be re-closed before re-storage.

- Allow the material that has been stored elsewhere to adapt to the temperature in the processing room while keeping the bag closed.

Packaging

- Xytron™ grades are supplied in polyethylene bags.

Moisture Content as Delivered

- Xytron™ PPS grades show hardly any moisture pick up. The moisture content is not specified.

Conditioning Before Molding

- To prevent moisture condensing on granules, bring cold granules up to ambient temperature in the molding shop while keeping the packaging closed.

Moisture Content Before Molding

- Since Xytron™ has a low moisture pick up and is not hygroscopic, still the advise is to dry Xytron™ G3080R for a short time. The advisable moisture level before molding is maximum 500 ppm.

Drying

- Hot air ovens or hopper driers can be used for pre-drying Xytron™ grades, however preferred driers are dehumidified driers with dew points maintained between -30 and -40°C / -22 and -40°F. Vacuum driers with N₂ purge can also be used.

Moisture content Time Temperature [%] [h] [°c] [°F] as delivered 2-6 130-140 266-284 Regrind

- Regrind can be used taking into account that this regrind must be clean/low dust content/not thermally degraded/dry, of same composition and similar particle size as the original material. The acceptable level of regrind depends on the application requirements (e.g. UL Yellow Card). Be aware that regrind can cause some small color deviations.